Fertilizer processing production line and method

A technology for production lines and fertilizers, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as misdetection, box friction damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

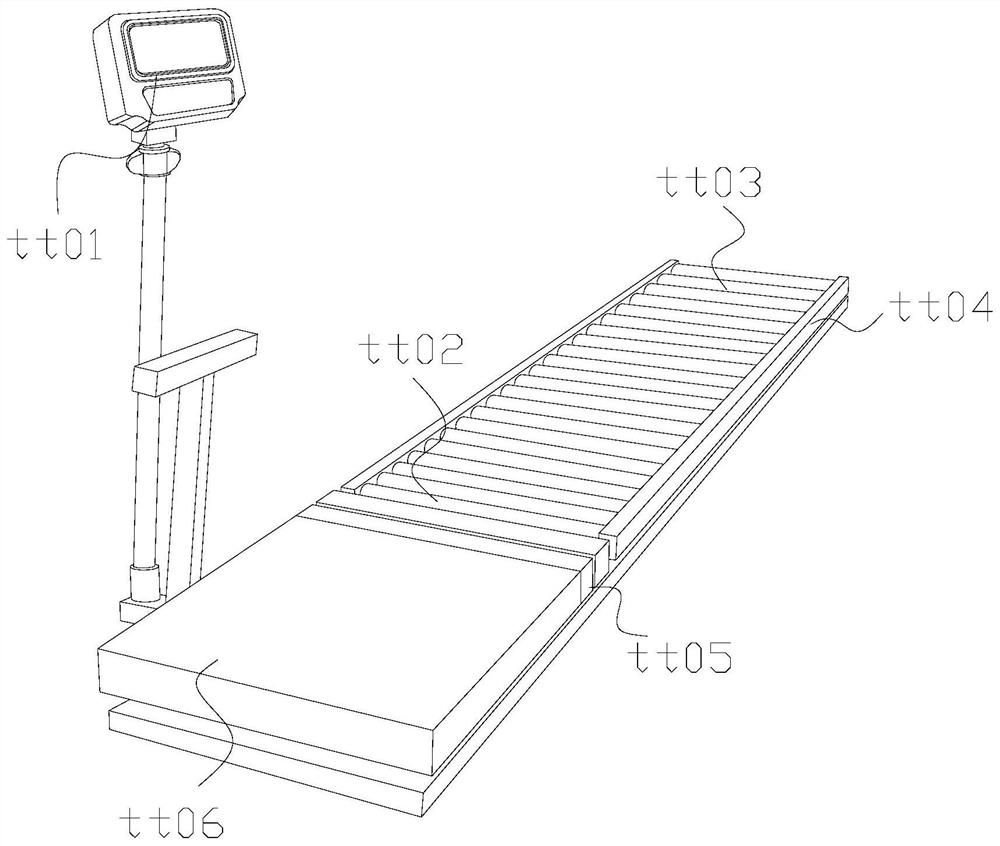

[0031] as attached figure 1 to attach Figure 5 Shown:

[0032] The invention provides a chemical fertilizer processing production line and method, the structure of which includes a display terminal tt01, a terminal roller tt02, a conveying cylinder tt03, a side support plate tt04, a heavy rail tt05, and a weighing surface tt06.

[0033] The display end tt01 is connected to the scale surface tt06, the end roller tt02 is connected to the delivery cylinder tt03 through the side support plate tt04, and the heavy lifting rail tt05 is installed on the outer surface of the scale surface tt06.

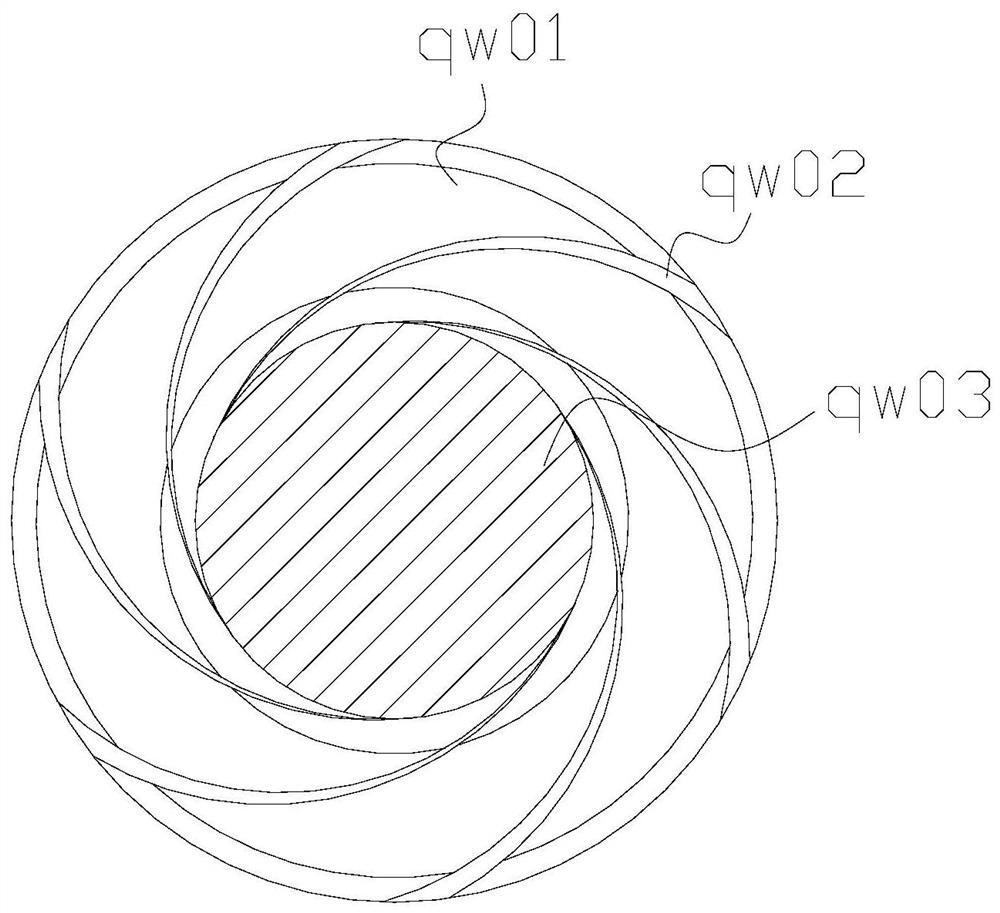

[0034] The end roller tt02 includes a support edge qw01, a rubber separation edge qw02, and a solid column qw03. The rubber separation edge qw02 is attached to the outer surface of the support edge qw01, and the support edge qw01 is connected to the solid column qw03. .

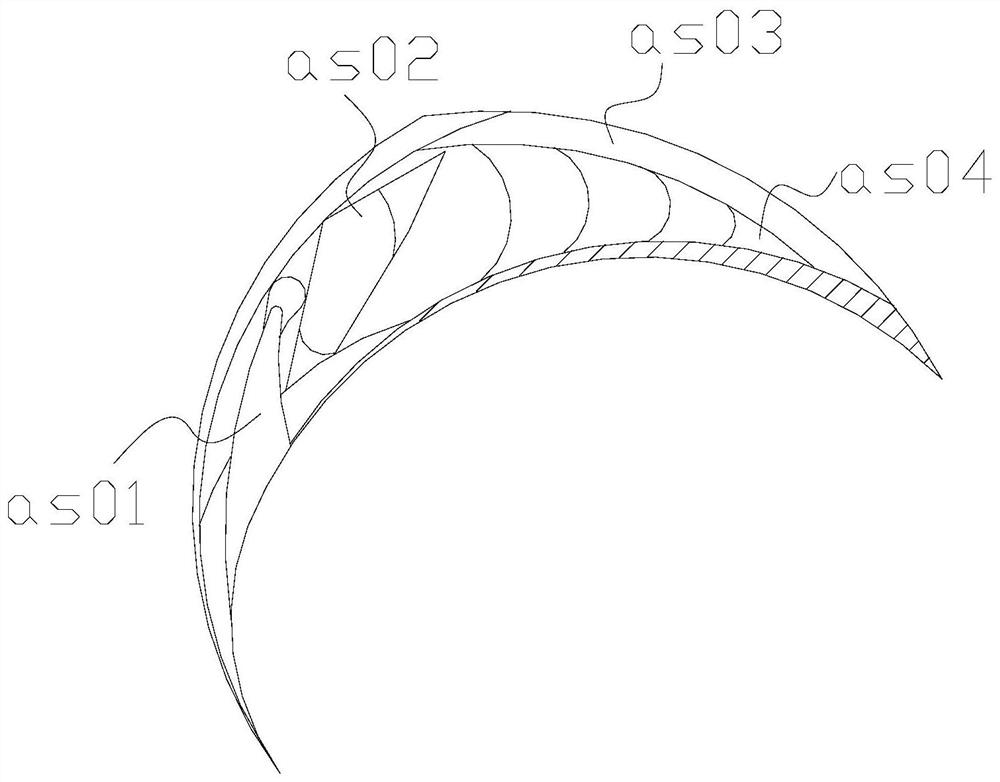

[0035] Wherein, the warping edge qw01 includes an inclination angle as01, an extension head as02, a top arc edge as03, ...

Embodiment 2

[0041] as attached Image 6 to attach Figure 7 Shown:

[0042] Wherein, the heavy warp fence tt05 includes an outer hard shell zxc1, a plastic arc edge zxc2, a pusher body zxc3, and a retaining wall zxc4, the rubber arc edge zxc2 is connected with the retaining wall zxc4, and the repeater body zxc3 is connected to the outer hard shell zxc1 connected, the retaining wall zxc4 is embedded inside the outer hard shell zxc1, the rubber arc edge zxc2 is provided with four and two in a group, the retaining wall zxc4 is a semicircular structure, and the push body zxc3 is at one end Under pressure, the other end will tilt in the opposite direction, the rubber arc zxc2 protects the outer layer and the inside, and the retaining wall zxc4 protects the inner wall.

[0043] Wherein, the revolving body zxc3 includes a pocket block b01, an expansion angle b02, a buckle extension angle b03, a rolling body b04, a middle ball b05, an arc rubber core b06, and an intermediate body b07, and the exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com