Processing equipment for polyethylene film

A polyethylene film and processing equipment technology, applied in metal processing, winding strips, sending objects, etc., can solve the problems of affecting the appearance of products, uneven ends of film rolls, and increasing the workload of manual processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

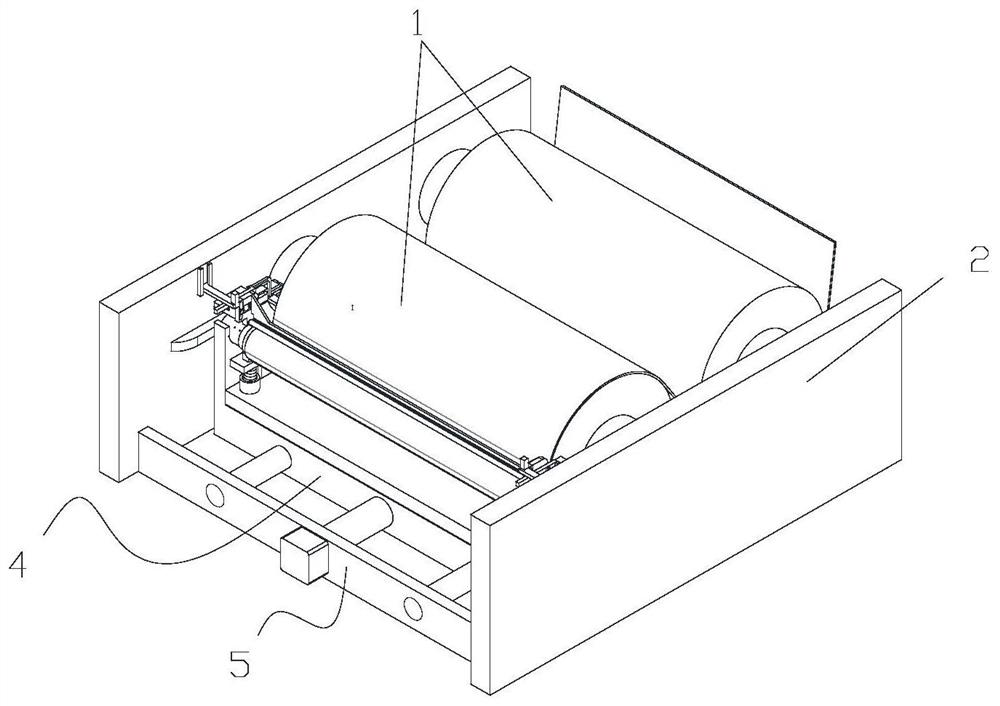

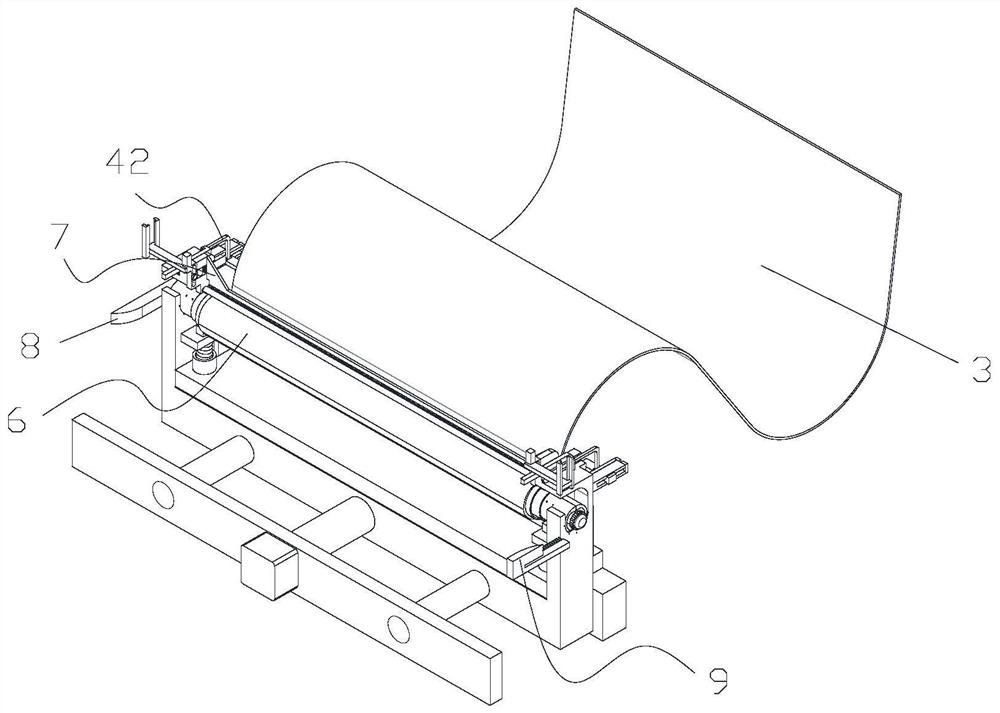

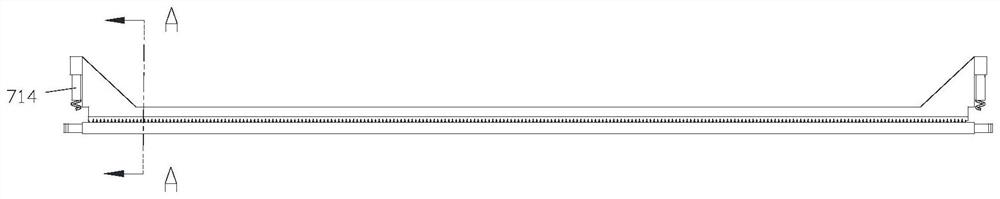

[0023] Such as Figure 1-10 Shown, a kind of processing equipment for polyethylene film, comprises a plurality of guiding cylinders that guide polyethylene film, is fixed on the two support plates that are used to support guiding cylinder on both sides of guiding cylinder, polyethylene film, is used to use Rolling device for polyethylene film into a roll, support table for supporting the roll device, displacement device for moving the support table, cutting assembly for cutting polyethylene film, first guide plate fixed on the support plate , the second guide plate fixed on the support plate; the cutting assembly includes a cutting knife, two horizontally placed upper turning ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap