Linkage shaft for cable reel and cable unfolding and lifting device

A technology of interlocking shaft and cable reel, which is applied in the field of interlocking shaft for cable reel and cable spreading and lifting device, can solve the problems such as shaking and jumping of the cable reel of the supporting shaft, affecting the efficiency of cable unfolding, etc., so as to reduce shaking and Jitter, prevent excessive pulling, correct curvature effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

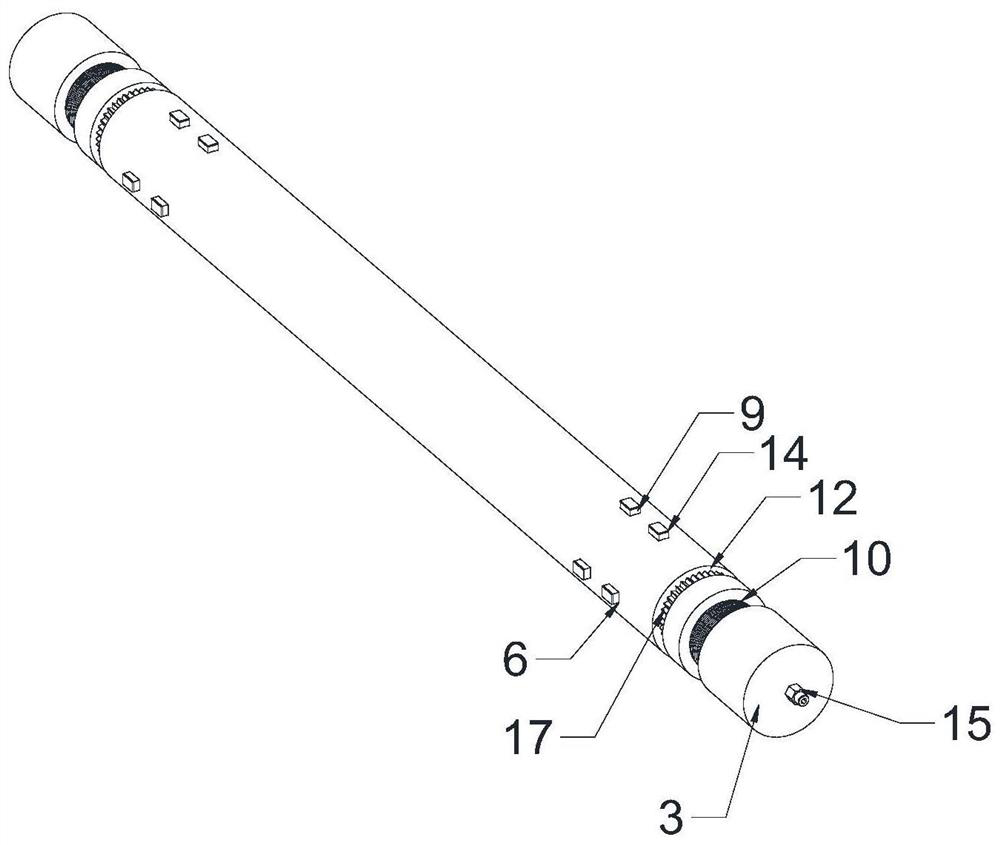

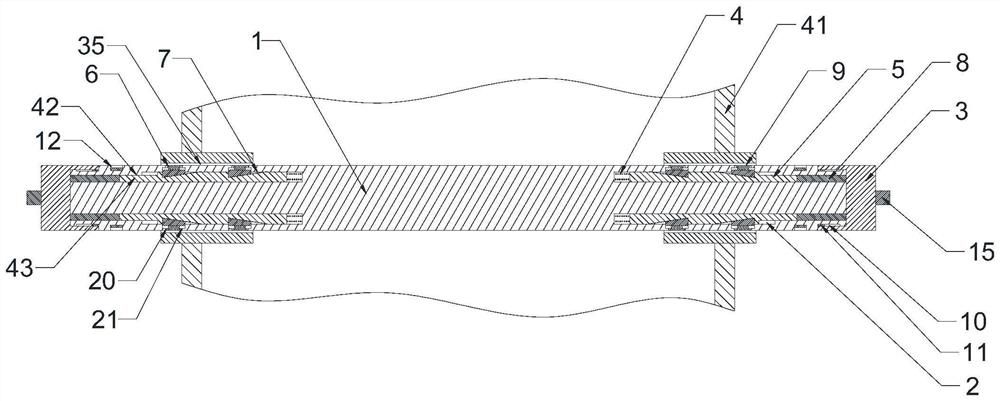

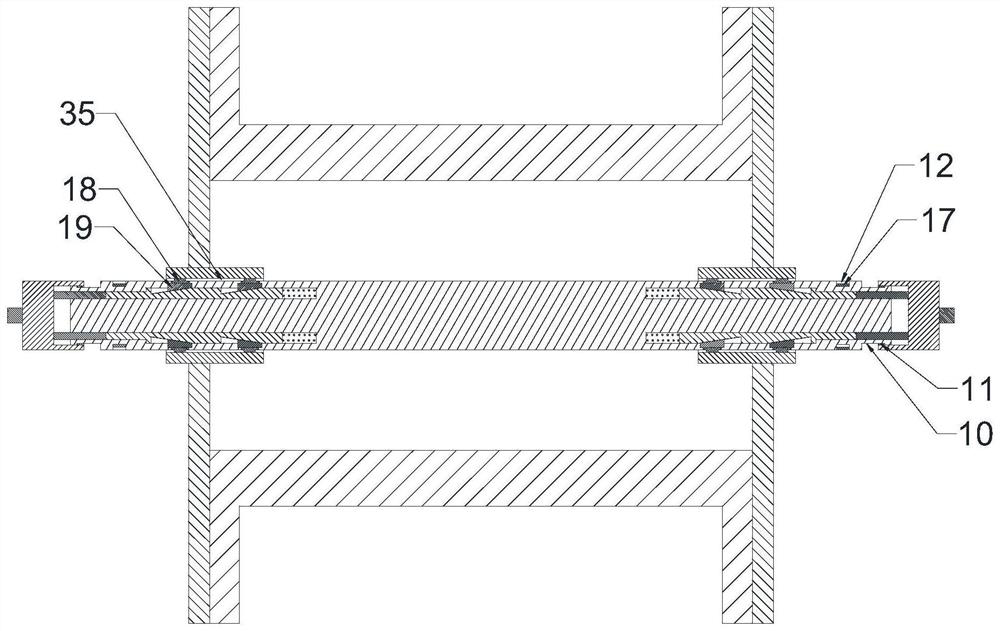

[0051] Such as Figure 1 to Figure 5 As shown, a connecting shaft for a cable reel includes a shaft body 1 and two end caps 3 that can be screwed with both ends of the shaft body 1 respectively, and both ends of the shaft body 1 are provided with a pressing assembly;

[0052] The abutment assembly includes an annular groove 2 opened at the end of the shaft body 1, the annular groove 2 runs through the outer end of the shaft body 1, and the groove bottom of the annular groove 2 along the axial direction of the shaft body 1 is connected by a sliding rod elastic member 4 There are several sliding rods 5 that can slide in the annular groove 2, and several sliding rods 5 are evenly distributed along the circumferential direction of the annular groove 2. The sliding rod 5 is provided with at least one sliding notch 7, and the sliding notch 7 The bottom of the groove is arranged on an inclined plane, and the groove depth of the sliding notch 7 is gradually deepened towards the area n...

Embodiment 2

[0067] In order to facilitate the braking of the shaft body 1, this embodiment makes the following further limitations on the basis of embodiment 1: both ends of the shaft body 1 are provided with brake assemblies;

[0068] The brake assembly includes several brake teeth A17 arranged in a ring on the outer surface of the shaft body 1 .

[0069] In this embodiment, the arrangement of the braking teeth A17 can form an uneven structure on the outer surface of the shaft body 1 , so that it is easier to brake the shaft body 1 by inserting and fitting. In addition, regardless of the circumferential state of the shaft body 1 , the circular arrangement of the brake teeth A17 is designed to easily brake the shaft body 1 .

[0070] In order to avoid accidental wear of the brake tooth A17, preferably, an annular brake groove 12 is formed on the outer surface of the shaft body 1, and the brake tooth A17 is located in the brake groove 12.

[0071] In this way, the braking tooth A17 does n...

Embodiment 3

[0073] This embodiment makes the following further limitations on the basis of Embodiment 2: the outer surface of the end of the shaft body 1 is provided with a concave shaft body limiting groove 10, and the shaft body limiting groove 10 is provided with a shaft body thread part;

[0074] The inner surface of the end cap 3 is provided with an end cap limiting protrusion 11 which can cooperate with the shaft body limiting groove 10, and the position limiting protrusion 11 is provided with an end cap threaded section which is threadedly matched with the shaft body threaded section.

[0075] In this embodiment, the setting of the shaft limit groove 10 and the end cover limit protrusion 11 can limit the limit displacement of the end cover 3, so as to prevent the end cover 3 from moving excessively or even detaching from the shaft body 1, which will affect the operation of this embodiment. reliability and stable performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com