Tin layer high-temperature-discoloration-resistant composition

A color-changing composition, high-temperature resistant technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

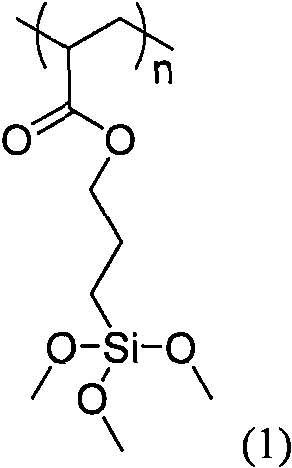

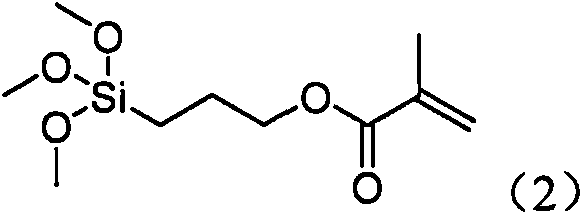

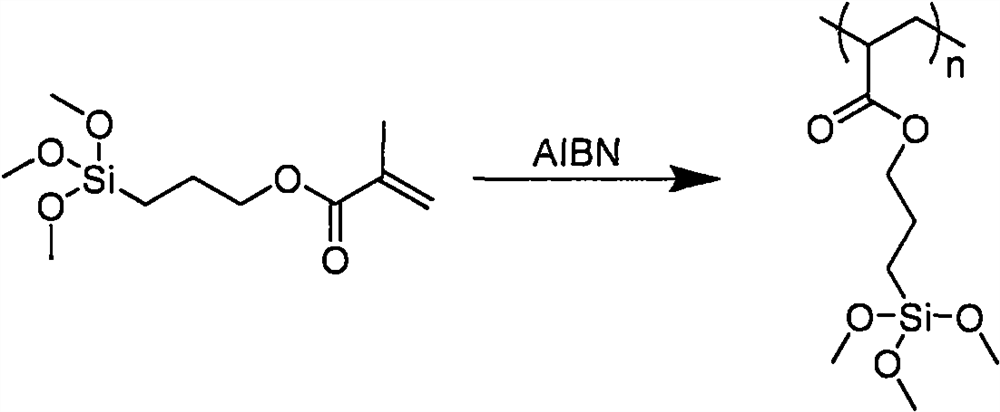

[0020] This example provides a polymer of γ-methacryloxypropyltrimethoxysilane as a monomer, its structural formula is shown in Table 1, and its synthetic route is as follows:

[0021]

[0022] Table 1: Polymer structural formula that embodiment 1 provides

[0023]

[0024] Preparation method of polymer P1

[0025] Under nitrogen protection, γ-methacryloxypropyltrimethoxysilane (24.81g, 100mmol), azobisisobutyronitrile AIBN (82.1mg, 0.5mmol), absolute ethanol (100mL) were added to In the two-necked flask, heat up to 70°C (can be any value in 60-80°C) and react for 12h (can be any value in 8-24h). The reaction solution was naturally cooled to room temperature. Anhydrous ethanol was distilled off under reduced pressure to obtain polymer P1. 1 H NMR (400MHz, CDCl 3 )δ(ppm): 4.06(t, 2H), 3.55(s, 9H), 2.13(br, 1H), 1.60-1.53(br, 4H), 0.58(t, 2H).

Embodiment 2

[0027] The configuration of the tin layer anti-high temperature discoloration composition is as follows:

[0028] Using isopropanol as a solvent, the polymer P1 of Example 1 was added in an amount of 8%, stirred evenly at room temperature, and dissolved completely.

Embodiment 3

[0030] Soak the tin layer anti-discoloration composition of the tin layer involved in Example 2 at room temperature for 10 seconds on the tin-plated layer of the lead frame, and then perform a reflow soldering application assessment test after three-stage countercurrent washing. The process is as follows:

[0031] a. Preheating, the temperature rises from room temperature to 150°C, the temperature rise rate is controlled at about 2°C / s, and the time in this temperature zone is 60-150s.

[0032] b. Uniform temperature, the temperature is from 150-217°C, and the temperature rises steadily and slowly, and the temperature rise rate is less than 1°C / s.

[0033] c. Reflux, the temperature is controlled at 217°C for 60-90s.

[0034] d. Cooling, the maximum temperature drop rate cannot exceed 4°C / s, and observe the application effect with the naked eye after cooling to room temperature.

[0035] After the lead frame tin plating layer treated with the tin layer anti-high temperature d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com