Silicon modified associative waterborne polyurethane thickener and its preparation method and application

A water-based polyurethane, associative technology, applied in the direction of coating, etc., can solve the problems of poor resistance to solvent interference, etc., achieve good thickening effect, lower requirements for synthesis conditions, and strong thickening performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

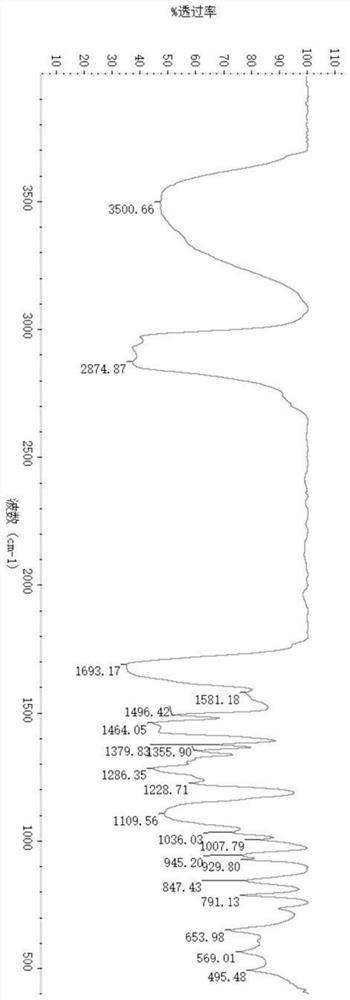

Image

Examples

Embodiment 1

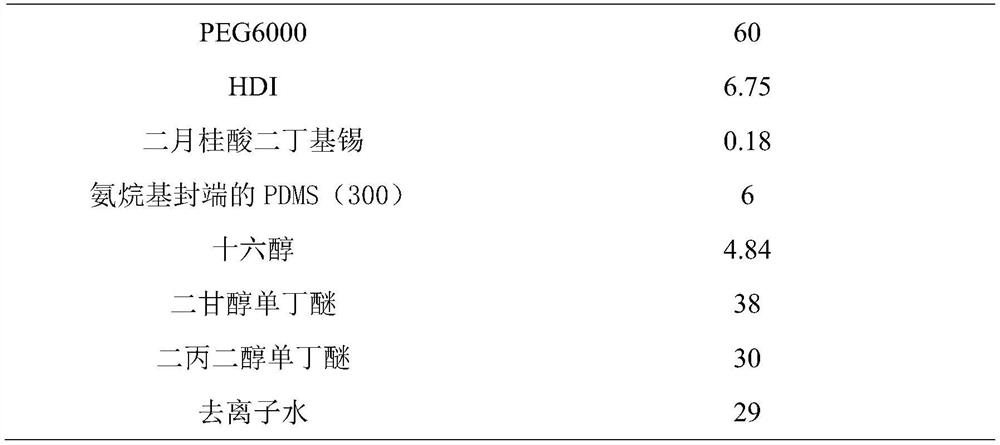

[0029] Raw material formula:

[0030] Table 1

[0031]

[0032] A preparation method of a silicon-modified associative water-based polyurethane thickener, comprising the steps of:

[0033] First add 60g of PEG6000 to the reaction vessel, raise the temperature to 100°C, and vacuum dehydrate for 3 hours until the water content is lower than 300ppm; then cool the polyethylene glycol to 60°C under nitrogen protection, and add 6g of aminoalkyl-terminated PDMS dropwise at one time (300), add 4.84g cetyl alcohol and 6.75g HDI successively after the dropwise addition, react at 70°C for 2h, then add 0.18g dibutyltin dilaurate, heat up to 100°C for 1h, cool down to 50°C, add 38g diglycol Alcohol monobutyl ether, 30g dipropylene glycol monobutyl ether and 29g deionized water were fully stirred for 30 minutes to obtain a white silicon-modified water-based associative polyurethane thickener with a solid content of 40%.

[0034] Thickener performance: The rotational viscosity at 25°C i...

Embodiment 2

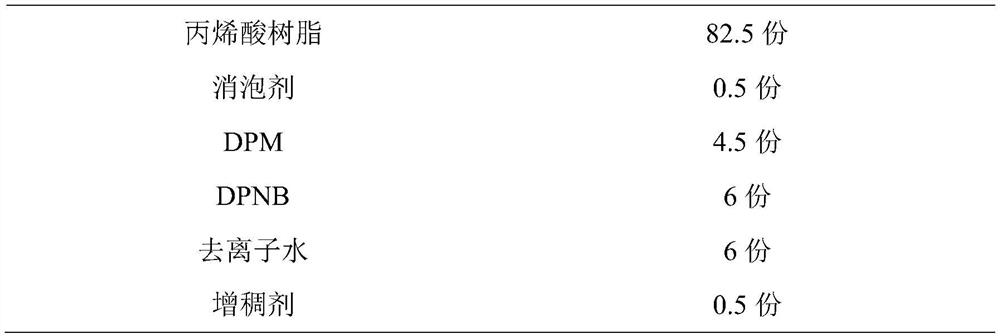

[0051] Raw material formula:

[0052] table 5

[0053]

[0054]

[0055] The preparation process comprises the following steps:

[0056] First add 20g PEG2000 to the reaction vessel, raise the temperature to 140°C, and vacuum dehydrate for 5 hours until the water content is lower than 300ppm; then cool the polyethylene glycol to 70°C under nitrogen protection, and add 20g of hydroxyalkyl-terminated PDMS dropwise at one time (1000), add 5.42g stearyl alcohol and 8.92g IPDI successively after the dropwise addition, react at 100°C for 5h, then add 0.2g N,N-dimethylcyclohexylamine, heat up to 120°C for 1-2h, cool down to At 60°C, add 20g of N-ethylpyrrolidone, 27g of dipropylene glycol monobutyl ether and 20g of deionized water, and stir thoroughly for 60 minutes to obtain a white silicon-modified water-based associative polyurethane thickener with a solid content of 40%.

[0057] Thickener properties: The rotational viscosity at 25°C is 6760mpas.

[0058] Thickener appli...

Embodiment 3

[0065] Raw material formula:

[0066] Table 8

[0067]

[0068] The preparation process comprises the following steps:

[0069] First add 80g of PEG8000 to the reaction vessel, raise the temperature to 120°C, and vacuum dehydrate for 4 hours until the water content is less than 300ppm; then cool the polyethylene glycol to 65°C under nitrogen protection, and add 12g of hydroxyalkyl-terminated PDMS dropwise at one time (600), add 4g tridecyl alcohol and 10.52g HMDI successively after the dropwise addition, react at 80°C for 2-5h, then add 1.6g organic bismuth, heat up to 110°C and react for 1-2h, cool down to 55°C, add 54g diglycol Alcohol monobutyl ether, 40g N-ethylpyrrolidone and 40g deionized water were fully stirred for 45min to obtain a white silicon-modified water-based associative polyurethane thickener with a solid content of 40%.

[0070] Thickener performance: The rotational viscosity at 25°C is 5760mpas.

[0071] Thickener application: Measurement scheme Referr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com