An ultrathin two-dimensional metal-organic framework material and its preparation method and application

A metal-organic framework, ultra-thin technology, applied in structural parts, battery pack parts, lithium batteries, etc., can solve the problem of irreversible attenuation of battery capacity, and achieve the effect of reducing the shuttle effect, simple and easy steps, and enriching the surface structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

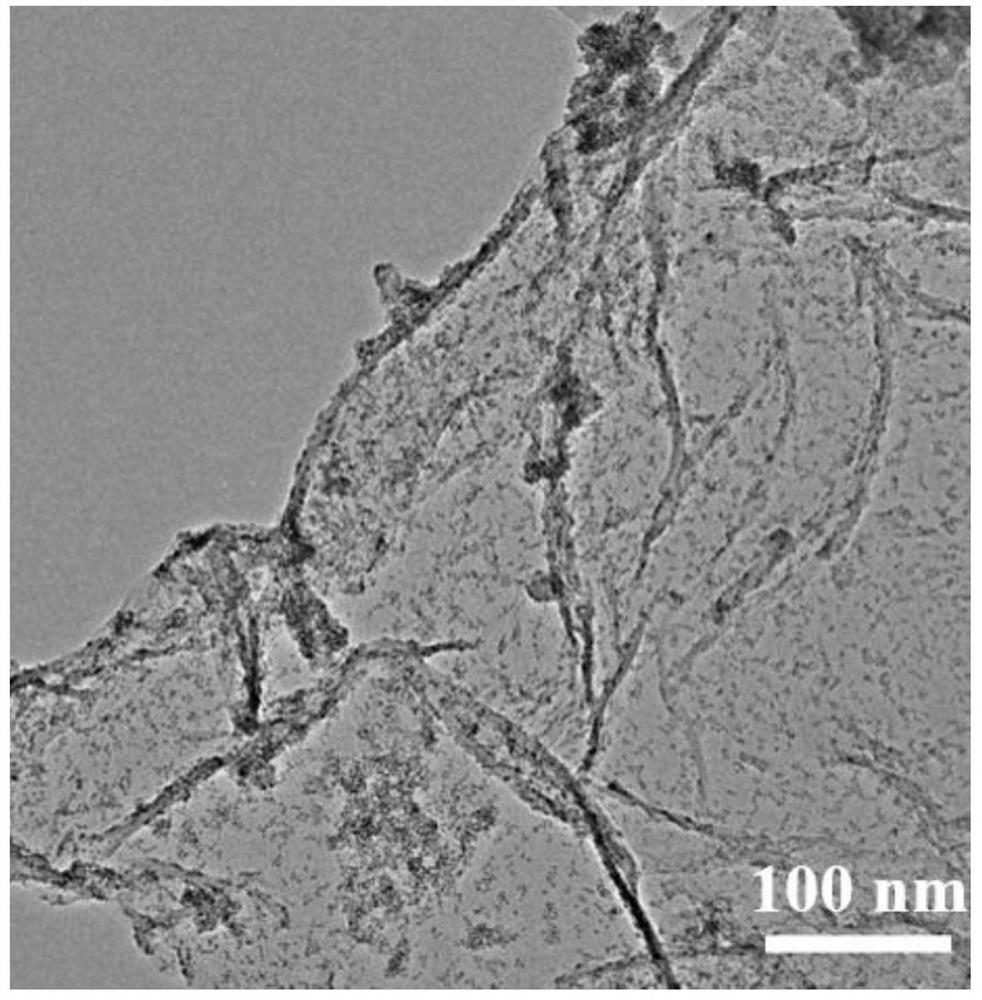

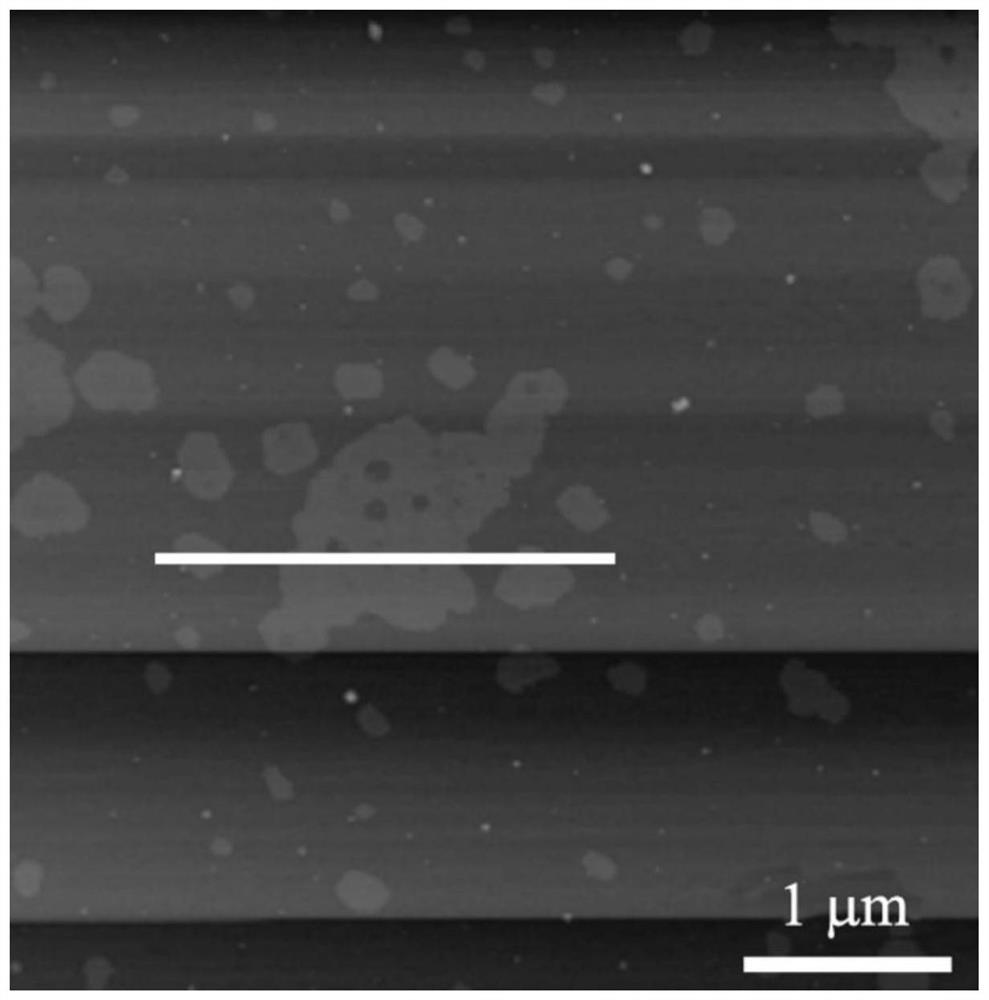

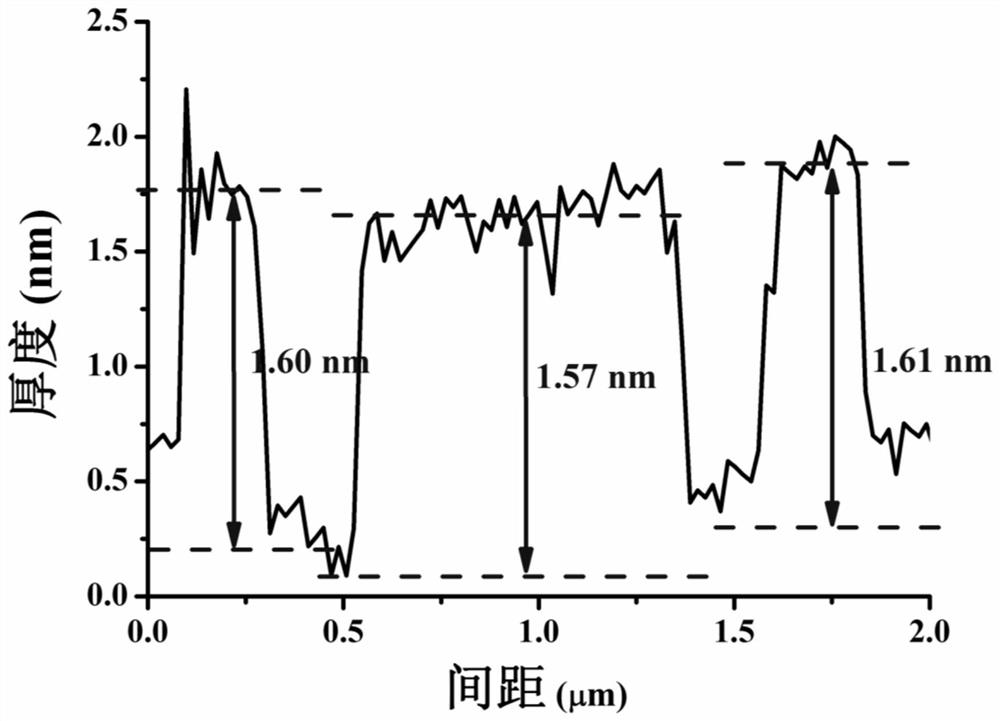

[0048] Example 1 Preparation of ultra-thin two-dimensional Co-MOF material

[0049] A method for preparing an ultrathin two-dimensional metal organic framework material, comprising the steps of:

[0050] (1) The three-dimensional layered columnar MOF precursor is subjected to ball milling, the ball milling is wet ball milling, the ball milling aid used in the ball milling is absolute ethanol, the speed of ball milling is 350r / min, the time of ball milling is 5h, and dried The temperature is 70°C to obtain the ball-milled precursor, and then weigh 15 mg of the ball-milled precursor and add it to 20 mL of solvent (N,N-dimethylformamide is selected), and the ultrasonic dispersion is uniform, and the ultrasonic time is 20 minutes. The frequency is 36kHz to obtain the mixed solution, and the O 3 / O 2 The mixed gas reacts, the reaction temperature is 0°C, the reaction time is 90min, O 3 / O 2 Mixed gas (O 3 The volume fraction is 50%) and the flow rate is 70mL / min to obtain the ...

Embodiment 2 2

[0057] Example 2 Preparation of two-dimensional Cu-MOF material

[0058] A method for preparing an ultrathin two-dimensional metal organic framework material, comprising the steps of:

[0059] (1) The three-dimensional layered columnar MOF precursor is subjected to ball milling, the ball milling is wet ball milling, the ball milling aid used in the ball milling is absolute ethanol, the speed of ball milling is 400r / min, the time of ball milling is 4h, and dried (The temperature is 60°C) to obtain the ball-milled precursor, then weigh 20mg of the ball-milled precursor and add it to 25mL solvent (N,N-dimethylformamide is selected), and the ultrasonic dispersion is uniform, and the ultrasonic time is 25min. The frequency of ultrasound is 40kHz to obtain the mixed solution, and the O 3 / O 2 The mixed gas reacts, the reaction temperature is 0°C, the reaction time is 90min, O 3 / O 2 Mixed gas (O 3 The volume fraction is 50%) and the flow rate is 70mL / min to obtain the reaction ...

Embodiment 3 2

[0066] Example 3 Preparation of two-dimensional Zn-MOF material

[0067] A method for preparing an ultrathin two-dimensional metal organic framework material, comprising the steps of:

[0068] (1) The three-dimensional layered columnar MOF precursor is subjected to ball milling treatment, the ball milling treatment is wet ball milling, the ball milling aid used in the ball milling treatment is absolute ethanol, the speed of the ball milling treatment is 300r / min, the time of the ball milling treatment is 6h, and dried (The temperature is 80°C) to obtain the ball-milled precursor, and then weigh 15 mg of the ball-milled precursor and add it to 30 mL of solvent (N,N-dimethylformamide is selected), and the ultrasonic dispersion is uniform, and the ultrasonic time is 30 minutes. The frequency of ultrasound is 36kHz to obtain the mixed solution, and the O 3 / O 2 The mixed gas reacts, the reaction temperature is 0°C, the reaction time is 90min, O 3 / O 2 Mixed gas (O 3 The volum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com