A kind of production method of high-toughness nickel-containing gear steel for heavy-duty transmission

A production method and high-toughness technology, applied in the field of metallurgy, can solve the problems of high oxygen content, high-grade banded structure, and difficult-to-control inclusions in gear steel, so as to reduce segregation of alloy elements, improve surface quality, and reduce the burden of heating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

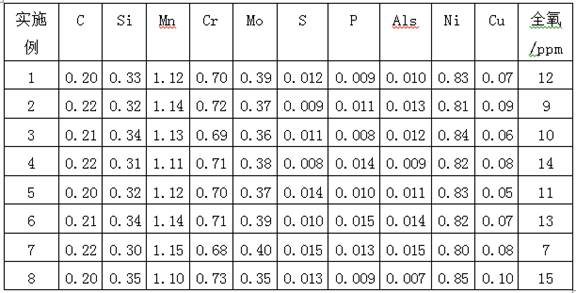

Examples

Embodiment 1

[0020] In this embodiment, a production method of high-toughness nickel-containing gear steel for heavy-duty transmissions includes converter smelting, LF refining, continuous casting, blanking, heating, and rolling processes. The specific process steps are as follows:

[0021] (1) Converter smelting process, using double slag process for smelting, dephosphorization to P to 0.028% at the beginning, then pouring 70% of the slag in the middle, returning to the zero position of the converter to re-slag with oxygen, adding active lime 21kg / t steel, magnesium balls 5kg / t steel, composite slag material 6kg / t steel, low-nickel pig iron with a phosphorus content of 0.060% and a nickel content of 12% was added in the early stage of smelting to replace the nickel plate, and coke was added to make up for the heat loss caused by the addition of cold material. The blowing process controls the carbon and oxygen product at the end of the blowing to 0.0021%. After the slag is removed from the...

Embodiment 2

[0028] In this embodiment, a production method of high-toughness nickel-containing gear steel for heavy-duty transmissions includes converter smelting, LF refining, continuous casting, blanking, heating, and rolling processes. The specific process steps are as follows:

[0029] (1) The converter smelting process adopts the double slag process, dephosphorizes to P to 0.025% at the beginning, then dumps 75% of the slag in the middle, returns to the zero position of the converter to re-slag with oxygen, and adds 23kg / t of active lime to steel and 4.5 magnesium balls kg / t steel, composite slag 7kg / t steel, low-nickel pig iron with a phosphorus content of 0.055% and a nickel content of 13% is added in the early stage of smelting to replace the nickel plate, coke is added to compensate for the heat loss caused by the addition of cold material, and the top and bottom of the double ring seam The double blowing process controls the carbon and oxygen product at the end of blowing to 0.00...

Embodiment 3

[0036] In this embodiment, a production method of high-toughness nickel-containing gear steel for heavy-duty transmissions includes converter smelting, LF refining, continuous casting, blanking, heating, and rolling processes. The specific process steps are as follows:

[0037] (1) Converter smelting process, using double slag process for smelting, initially dephosphorized to P to 0.026%, then dumped 69% of the slag in the middle, returned to the zero position of the converter to re-slag with oxygen, added active lime 22kg / t steel, magnesium balls 4.8 kg / t steel, composite slag material 6.5kg / t steel, low-nickel pig iron with a phosphorus content of 0.058% and a nickel content of 11% was added in the early stage of smelting to replace the nickel plate, coke was added to compensate for the heat loss caused by the addition of cold material, and the double-ring seam roof Bottom double blowing process controls the carbon and oxygen product at the end of blowing to 0.0018%. After th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com