Concrete paver for civil engineering

A concrete and paver technology, applied in construction, road, road repair and other directions, can solve problems such as reducing production efficiency, affecting the effect of paving and flattening, and increasing the workload of builders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Reference will now be made in detail to the exemplary embodiments, examples of which are illustrated in the accompanying drawings. When the following description refers to the accompanying drawings, the same numerals in different drawings refer to the same or similar elements unless otherwise indicated. The implementations described in the following exemplary examples do not represent all implementations consistent with the present disclosure. Rather, they are merely examples of apparatuses and methods consistent with aspects of the presently disclosed embodiments as recited in the appended claims.

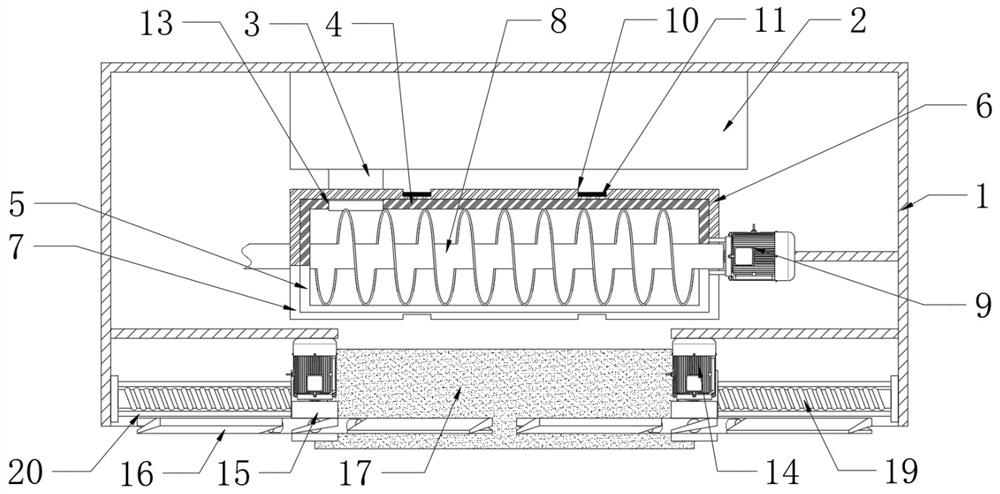

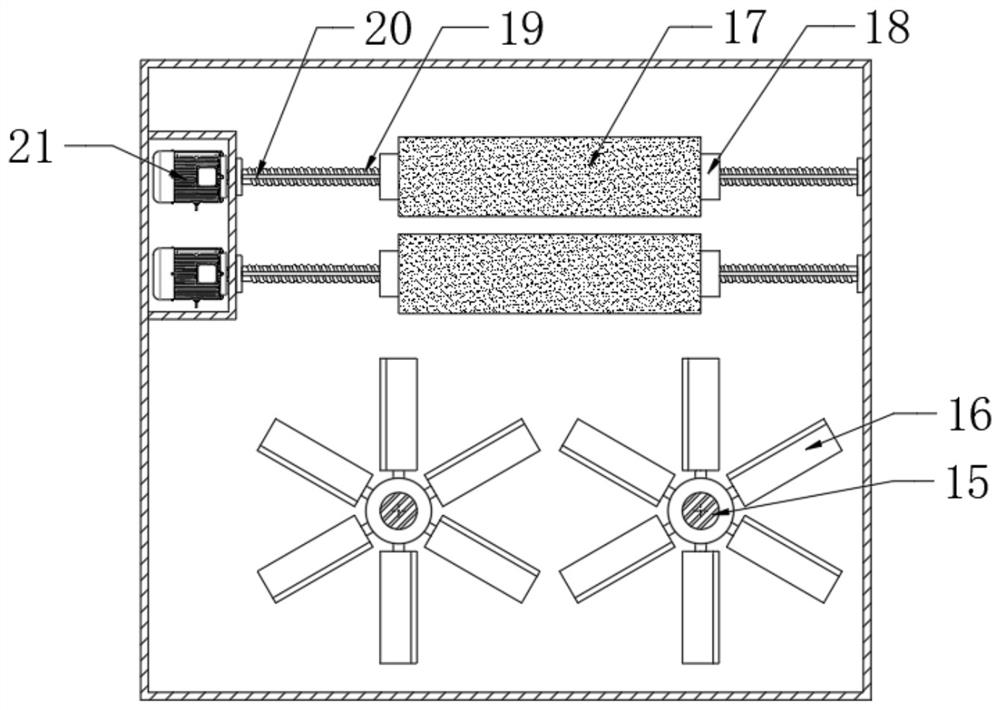

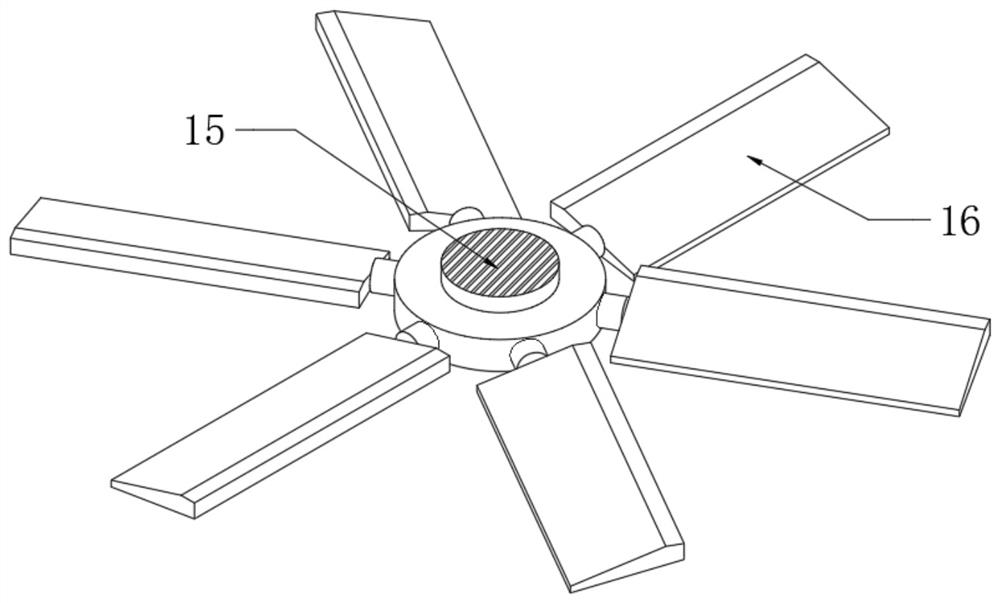

[0022] Such as Figure 1~3 As shown, in the embodiment of the present invention, a concrete paver for civil works includes: a cabinet 1, a fixed cylinder 4 and a rotating cylinder 6, a material storage box 2 is installed on the cabinet 1, and the fixed cylinder 4 is fixed Installed in the case 1, the storage box 2 is connected to the fixed cylinder 4 through the connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com