Hanging machine for wide bridge construction

A technology of bridge construction and hanging machine, which is applied in the direction of bridge, bridge construction, erection/assembly of bridges, etc. It can solve the problems of large sliding collision, loss of bridge-slab fit and low bridge-slab fit, and achieve anti-knock frame protection The effect of balance adjustment improvement, improvement of protection and tightness, and improvement of splicing fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

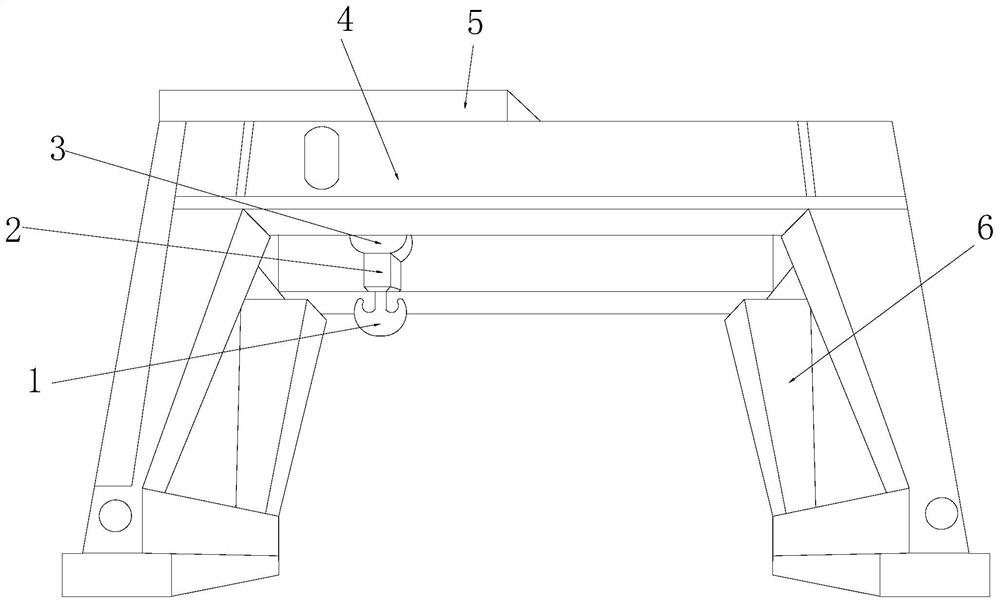

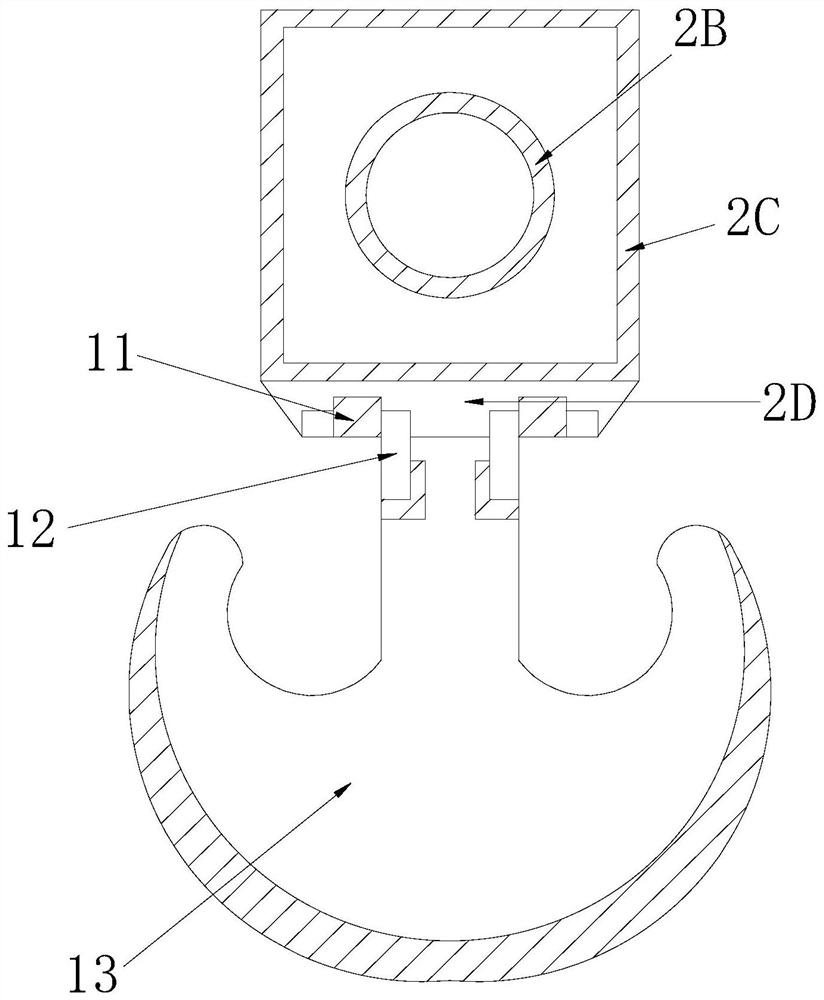

[0035] see Figure 1-Figure 8 , the present invention provides a kind of hanging machine for wide bridge construction, its structure comprises: barb kettle frame block 1, wheel disc support groove block 2, hinge roller plate groove 3, beam column block 4, sliding hanging plate 5, support Column 6, the wheel support slot block 2 is nested under the bottom of the hinge roller pan slot 3 and is on the same vertical plane, the barbed still frame block 1 is inserted into the wheel support slot block 2 Under the bottom, the hinge roller pan groove 3 is mechanically connected with the sliding hanging plate 5 through a chain and is perpendicular to each other. The sliding hanging plate 5 is close to the top surface of the beam column block 4 and is on the same horizontal plane. The supporting column 6 is welded together with the beam column block 4 and is perpendicular to each other. The wheel support slot block 2 is provided with a cross brace right-angle frame 2A, a winding wheel fr...

Embodiment 2

[0043] see Figure 1-Figure 8 , the present invention provides a kind of wide-type bridge construction hanger, other respects are identical with embodiment 1, and difference is:

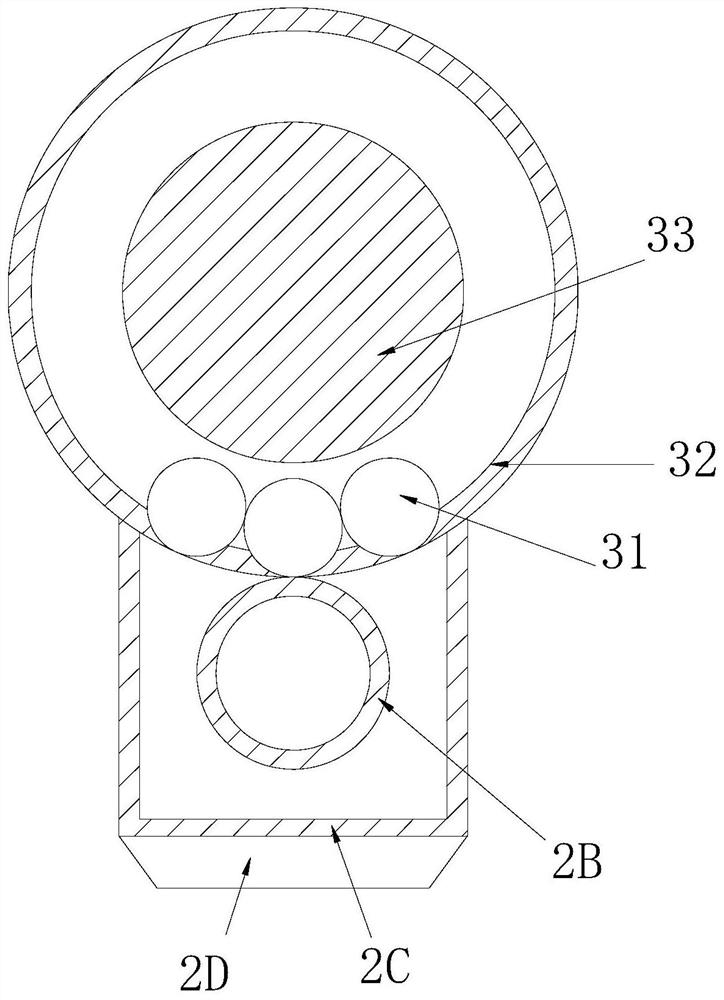

[0044] see image 3 , the hinge roller disc groove 3 is composed of a swivel frame ball 31, a ring rail frame groove 32, and a solid roller bar 33. The swivel frame ball 31 and the ring rail frame groove 32 adopt clearance fit, and the ring rail frame groove 32 and The solid roller bar 33 is nested into one body, and the rotation of the solid roller bar 33 is wrapped and pressed by the ring rail frame groove 32 to ensure the linkage groove effect of the chain belt pull buckle slide plate and the base hoisting.

[0045] see Figure 6 , the swing frame ball 31 is composed of a propeller frame rod 311, an ellipsoidal spring wire groove 312, and an arc ball groove 313. The propeller frame rod 311 is mechanically connected with the arc valve ball groove 313 and the axes are collinear, so The ellipsoida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com