Mechanical light nail thorn anchoring pile and construction method

An anchoring pile, mechanical technology, applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of difficult transportation, heavy raw material weight, complicated grouting construction process, etc., to ensure the installation efficiency and reduce the transportation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

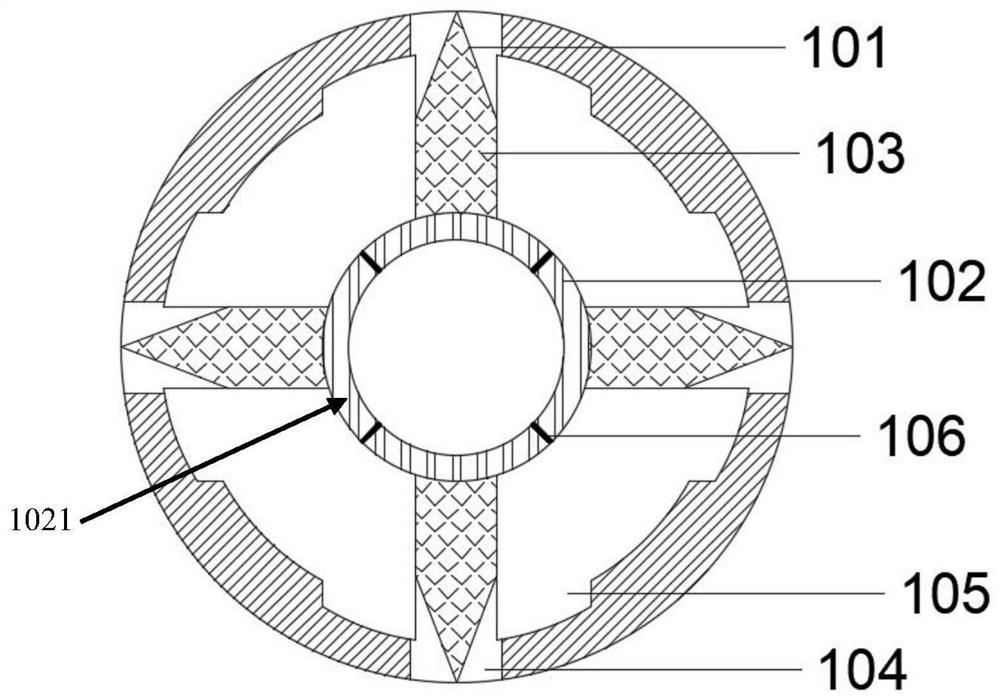

[0034] Embodiment 1: The mechanical light nailing anchor pile according to the present invention includes an anchor pile body 10, a pile cap 20 arranged at the upper end of the anchor pile body 10, a spud shoe 30 arranged at the lower end of the anchor pile body 10, and a pile cap 30 arranged at the lower end of the anchor pile body 10. The drilling mechanism 40 and the impact pile 50 at the bottom of the boot 30. The axis described in the present invention is Figure 10 The direction of the Y-axis, the radial direction is the same as Figure 10 In the direction parallel to the direction of the X-axis, the radial pressure is the force of outward extrusion starting from the axial centerline of the anchor pile.

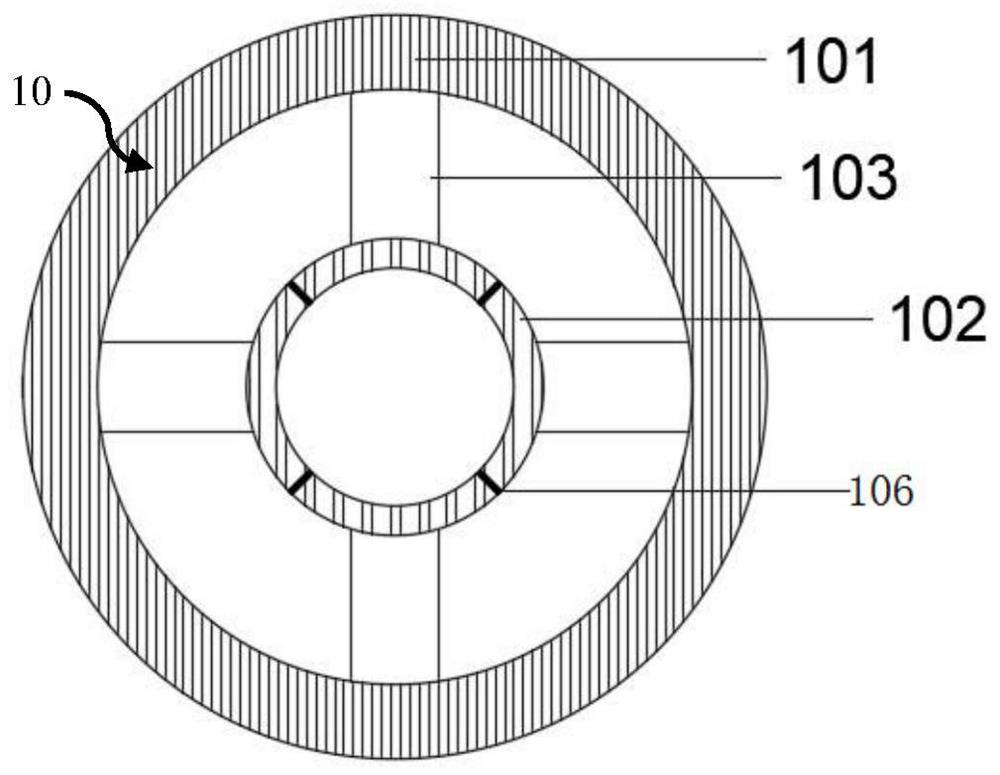

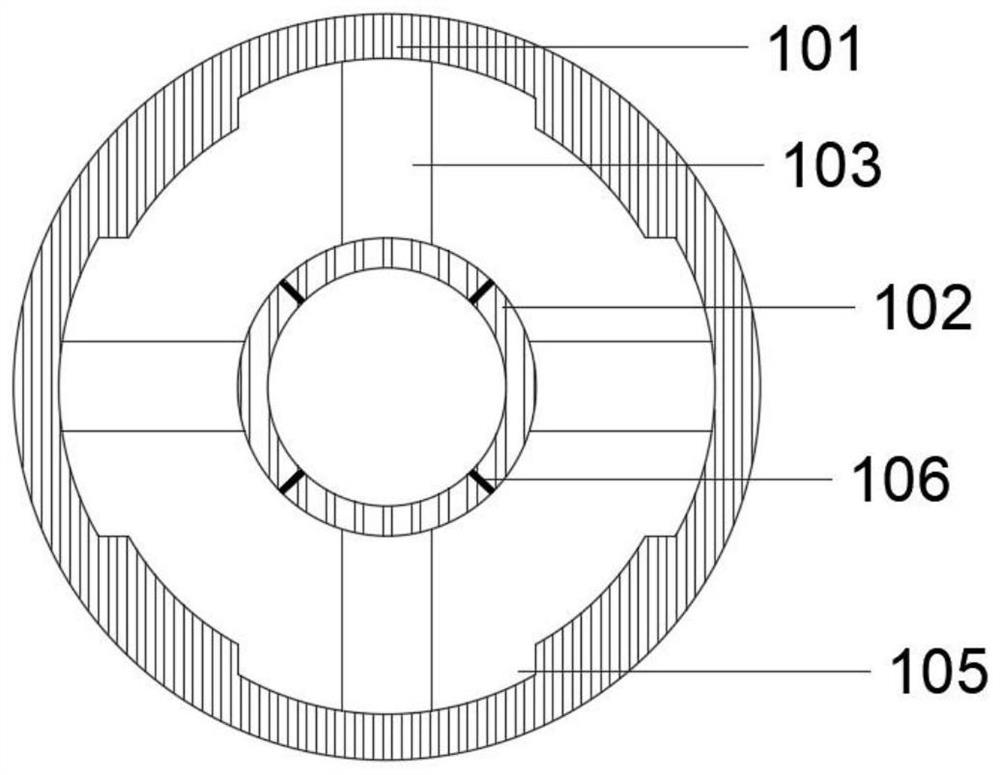

[0035] The anchor pile body 10 includes an outer tube 101 and an inner tube 102 disposed inside the outer tube 101 that can be separated under radial (squeeze) pressure. The outer tube 101 and the inner tube 102 are both hollow tubular structures, and the inner and out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com