Floor system comprising box beams and construction method thereof

A construction method and technology of box girders, which are applied to building structures, floor slabs, buildings, etc., can solve problems such as the inability to meet the net height limit of basements, complex floor construction, and large spans of floor slabs, etc., to achieve enhanced rigidity and convenience The effect of hoisting and speeding up the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

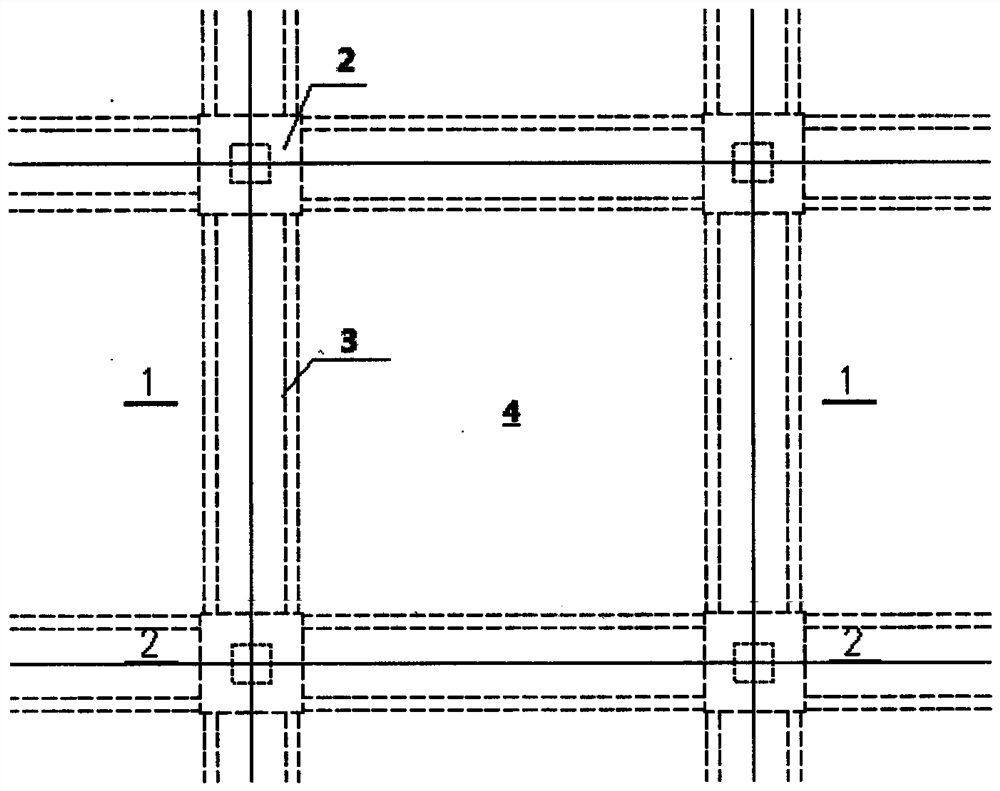

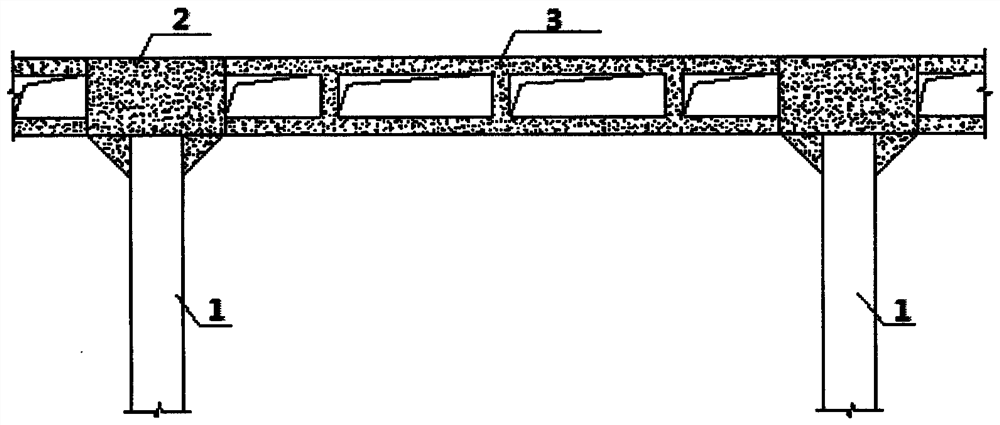

[0035] see Figure 1-3 , a floor system comprising a box girder of the present invention, comprising: a column 1, a column cap 2, a box girder 3, and a floor 4, the column cap 2 is located at the top of the column 1, and the box girder 3 Erected between two adjacent column caps 2 and arranged in two directions, the floor slab 4 is arranged between the box beams 3 to form several grid structures, and the floor slab 4 is located in the grid ; The box beam 3 is a rectangular structure; the box beam (3) is a concrete structure or a steel structure; the box beam 3 is a prestressed structural beam.

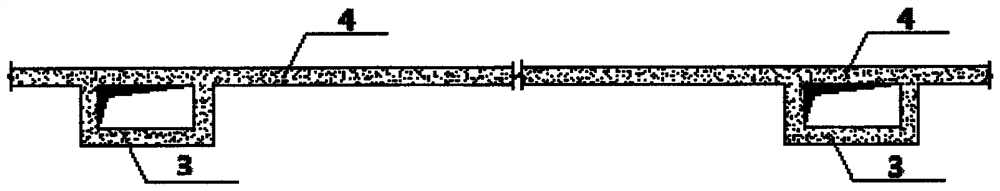

[0036] see Figure 4 , preferably, the box girder 3 has multiple cavities.

[0037] see Figure 5 , preferably, the box girder 3 is a variable section beam.

[0038] see Figure 6 , Preferably, the box girder 3 is a haunched girder. Further, the haunching is a horizontal or vertical haunching structure.

[0039] join Figure 7 , the box girders can also be arranged in one direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com