Efficient combined distributor structure for refrigerating system heat exchanger

A refrigeration system and heat exchanger technology, applied in refrigeration components, heat exchanger shells, indirect heat exchangers, etc., can solve problems such as leakage, uneven liquid separation, inconvenient disassembly and assembly, and avoid liquid leakage and disassembly. Inconvenient installation and the effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in further detail:

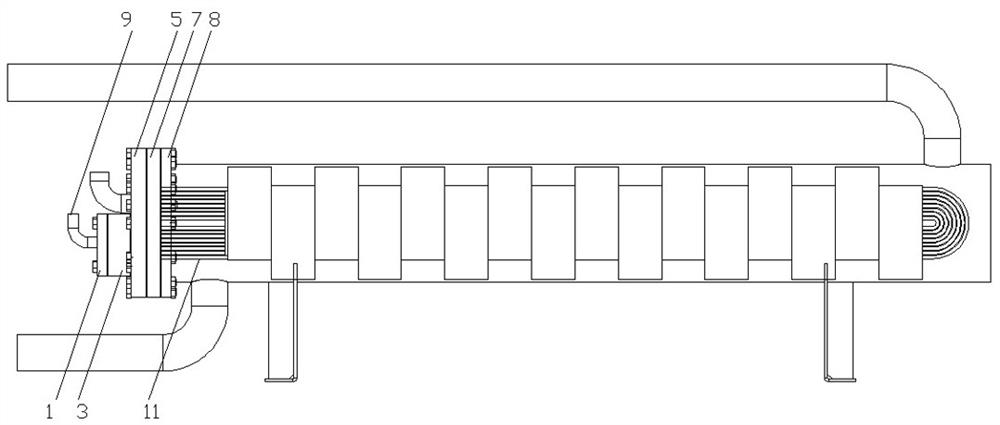

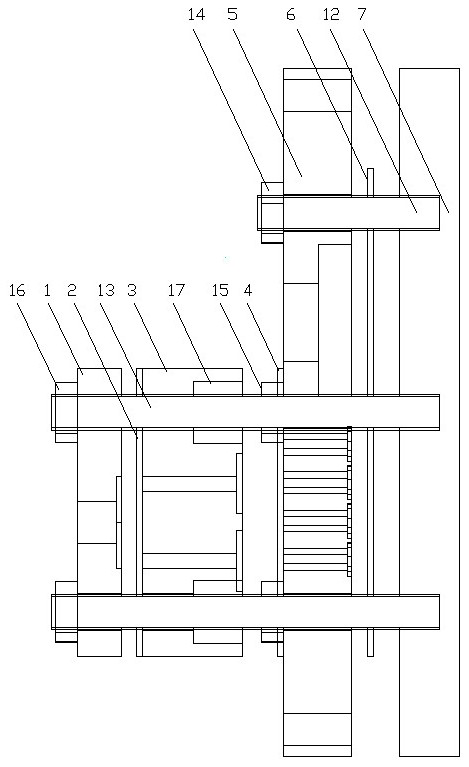

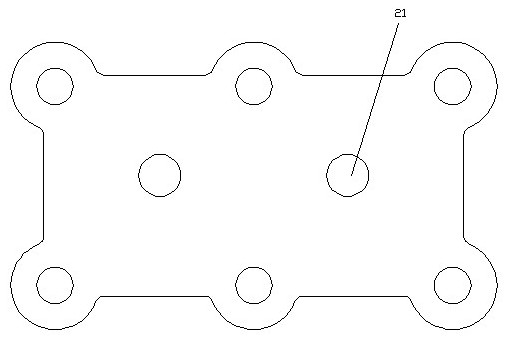

[0022] like figure 1 and 2 As shown, a high-efficiency combined distributor structure for heat exchangers in refrigeration systems, including sequentially connected cover plate 1, first gasket 2, distribution plate 3, second gasket 4, end cover 5, third Gasket 6, tube sheet 7, end cover 5, and tube sheet 7 are fixedly installed on the shell end face 8 of the heat exchanger through flanges. The tube sheet 7 is processed with a plurality of liquid inlet holes 10, and the liquid inlet holes 10 are connected with the heat exchange The heat exchange tubes 11 in the device are correspondingly communicated. Three end cap screws 12 and six cover plate screws 13 extend vertically outward from the outer end surface of the tube plate 7 , and the ends of each screw are screwed into the tube plate 7 through external threads or welded to the tube plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com