A kind of transformer hot spot temperature measurement system and method

A measurement method and technology of hot spot temperature, applied in transformer testing, thermometers based on physical/chemical changes, temperature maps, etc. Improved maintenance efficiency and operational reliability, high sensitivity and wide temperature measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Ultrasonic temperature measurement is a kind of acoustic temperature measurement. It adopts a non-contact temperature measurement method to measure the temperature based on the functional relationship between the propagation speed of ultrasonic waves in solid, liquid, gas and other media and the temperature of the medium. In an ideal gas, the propagation velocity of ultrasonic waves is proportional to the square root of the temperature of the medium; in most liquids, the propagation velocity of ultrasonic waves is linearly related to temperature; in general solids, the propagation velocity of ultrasonic waves decreases with increasing temperature. The speed of propagation in the medium can measure the temperature of the medium.

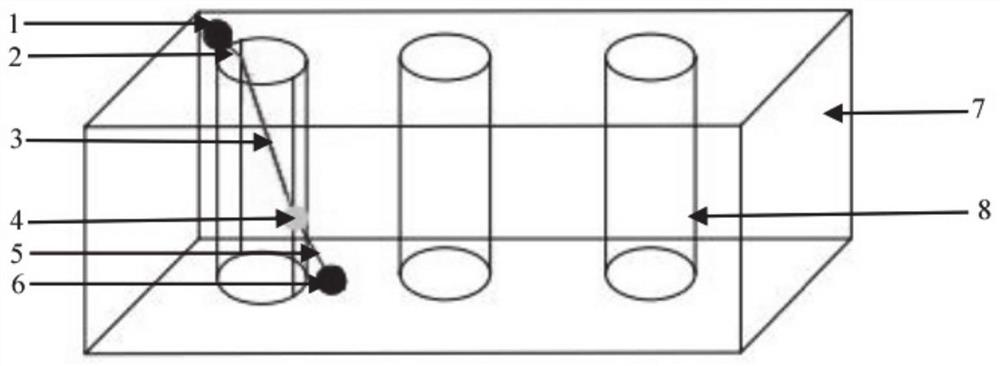

[0027] The method of ultrasonic real-time measurement of the hot spot temperature of transformer windings proposed in the present disclosure involves placing an appropriate number of ultrasonic sensors on the outer wall of the transformer, and t...

Embodiment 2

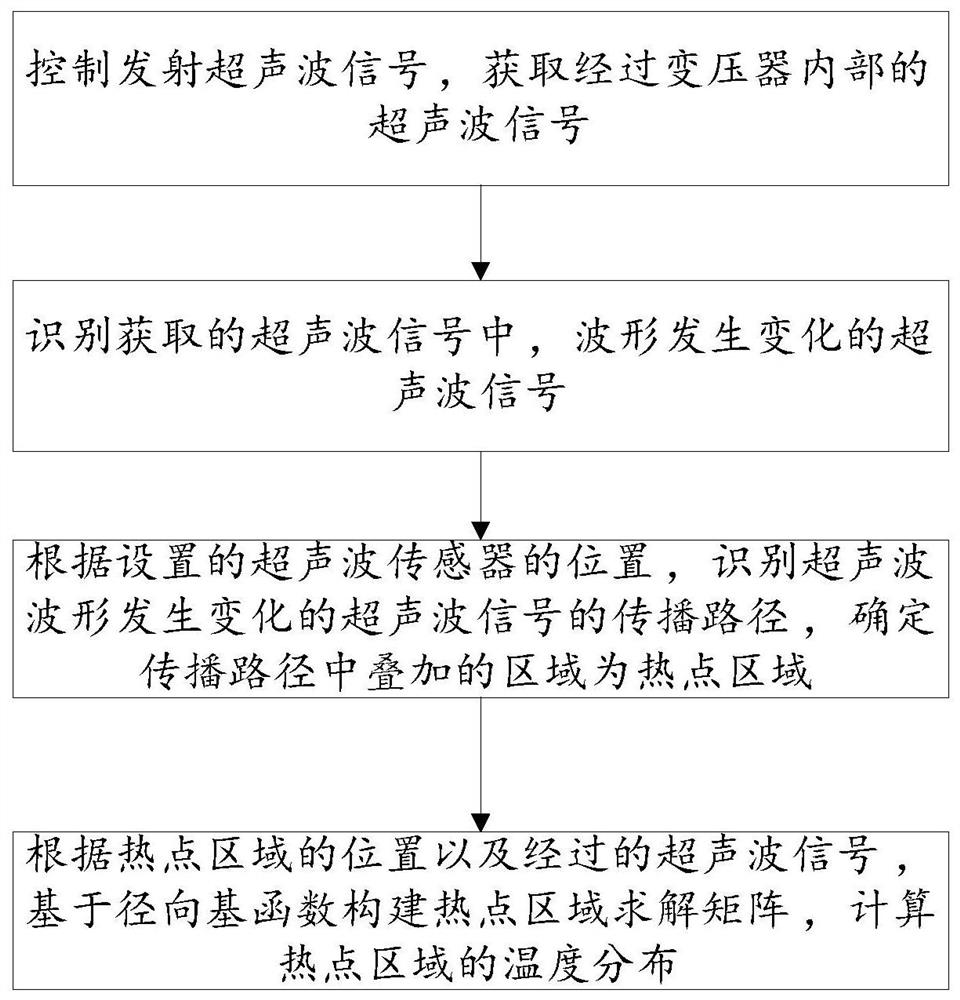

[0034] Based on the above measurement system, the present embodiment provides a method for measuring the hot spot temperature of a transformer. The method can be implemented in a processor in the measurement system, and includes the following steps:

[0035] Step 1. Transmit an ultrasonic signal, and obtain the ultrasonic signal received by the ultrasonic sensor arranged on the outer wall of the transformer tank to be tested, that is, to obtain the ultrasonic signal passing through the inside of the transformer

[0036] Step 2. Identify the ultrasonic signal whose waveform changes in the acquired ultrasonic signal;

[0037] Step 3: Identify the propagation path of the ultrasonic signal whose ultrasonic waveform changes according to the set position of the ultrasonic sensor, and determine that the superimposed area in the propagation path is a hot spot area;

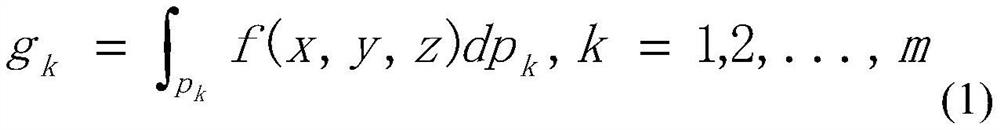

[0038] Step 4. According to the position of the hot spot and the ultrasonic signal passing through, the hot spot soluti...

Embodiment 3

[0090] This embodiment provides an electronic device, including a memory, a processor, and computer instructions stored in the memory and executed on the processor. When the computer instructions are executed by the processor, the steps described in the method of Embodiment 2 are completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com