FPGA-based buried pipeline damage harmonic magnetic field detection system and implementation method

A harmonic magnetic field and detection system technology, applied in the direction of material magnetic variables, etc., to achieve the effect of improving processing speed and throughput, reliable and accurate correction algorithm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In the following description, in order to more accurately and clearly describe the advantages of the technical solutions of the present invention, further elaborations will be made in conjunction with the accompanying drawings and specific embodiments. In the following description, detailed descriptions of well-known systems, circuits, and methods are omitted so as not to obscure the description of the present invention with unnecessary detail. However, it should be clear to those skilled in the art that the present invention can also be implemented in other embodiments without these specific details, and the embodiments without inventive improvements all belong to the protection scope of the present invention.

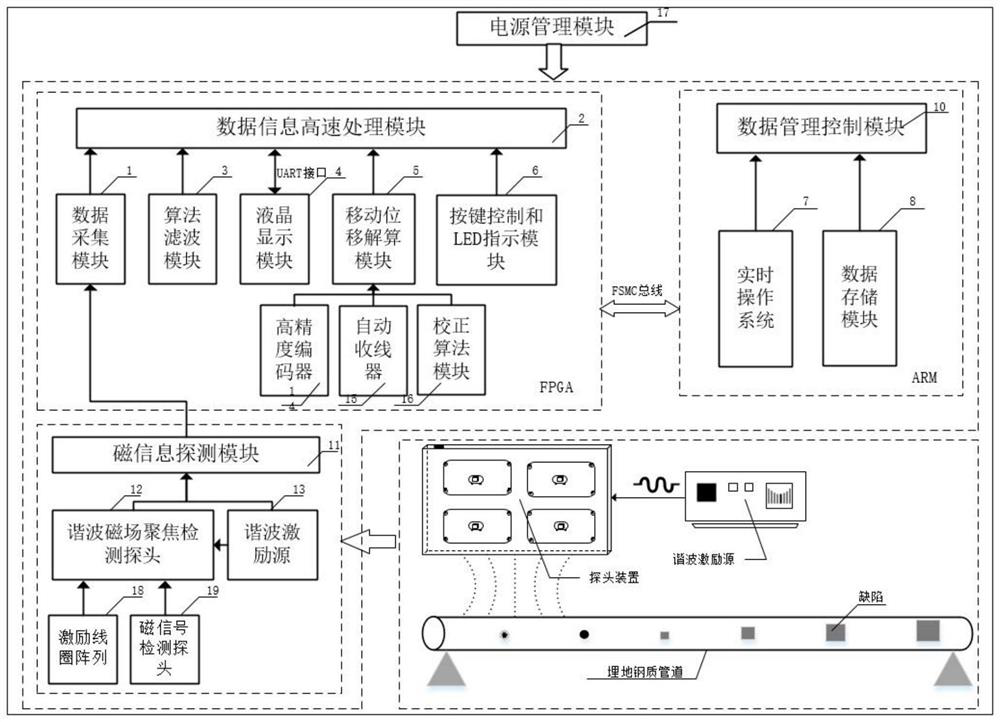

[0035] In order to realize the harmonic magnetic field detection technology of buried steel pipeline damage, the present invention designs a buried pipeline damage harmonic magnetic field detection system based on FPGA, that is, the detection probe detects at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com