Pressing block for adding liquid into sample, liquid adding assembly and liquid adding needle cleaning method

A technology for adding liquid needles and samples, which is applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., and can solve the problems of large space occupation, complex analyzer structure design, unfavorable instrument simplification and miniaturization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

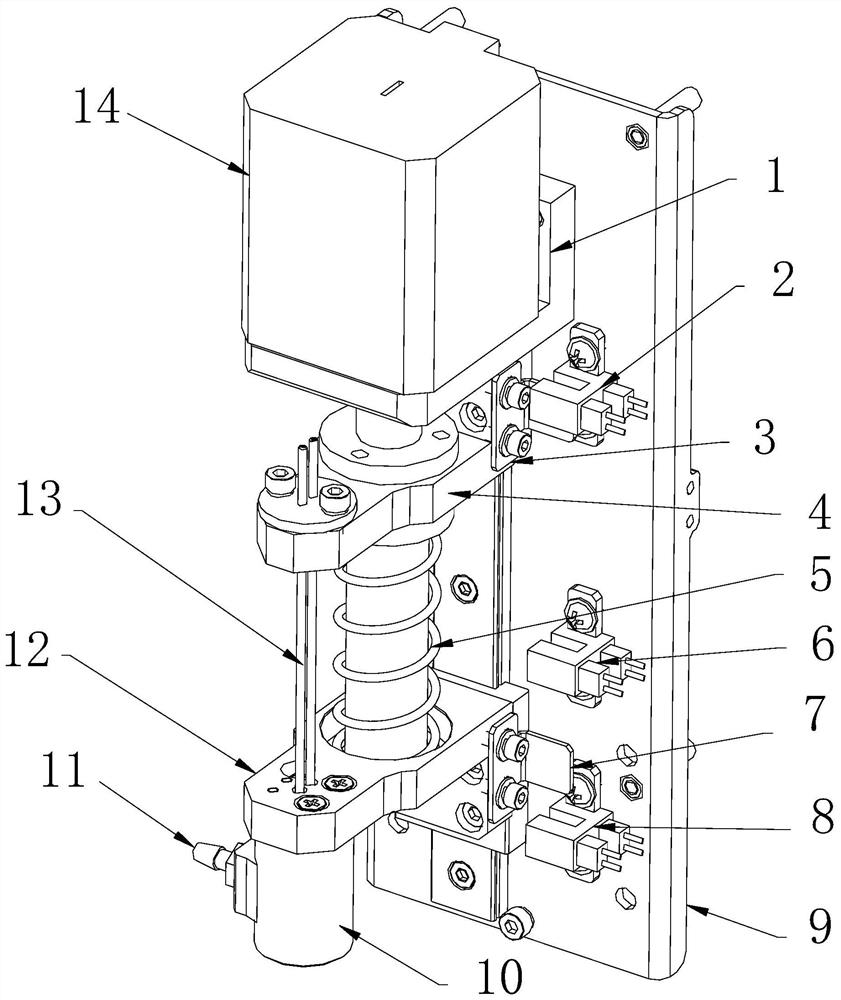

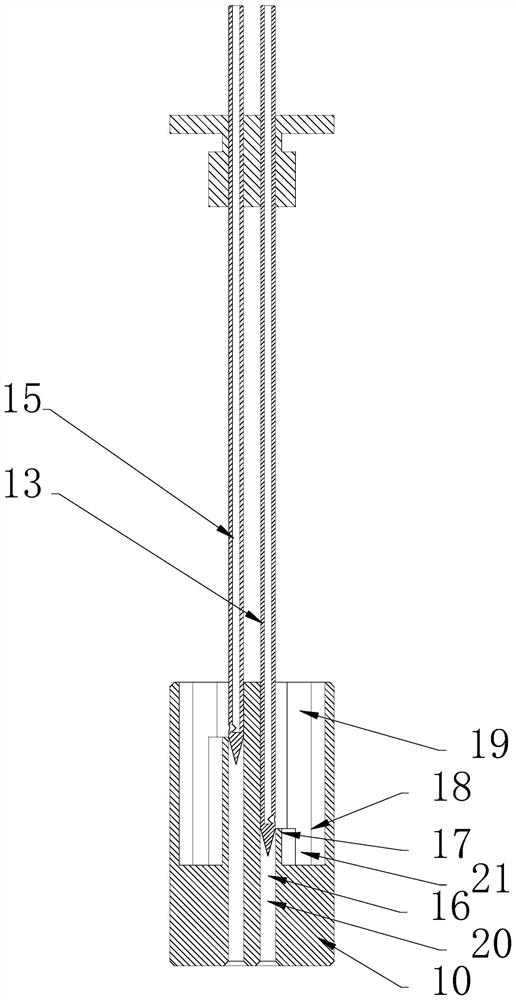

[0035] Such as Figure 1 to Figure 2 As shown, the briquetting block used for adding liquid to the sample includes a block-shaped briquetting body 10, and the briquetting body 10 is provided with a through hole 16 passing through a pair of opposite ends thereof, and the through hole 16 includes a The liquid needle 13 passes through the straight section of the briquetting body 10; the through hole 16 includes a first hole section 19 at one end and a second hole section 20 at the other end, the first hole section 19 and the second hole section The hole segments 20 are connected, and the cross-sectional area of the first hole segment 19 is greater than the cross-sectional area of the second hole segment 20; when the outlet of the liquid-feeding needle 13 is located in the first hole segment 19, the first hole segment The space of the hole section 19 can be used to form an accommodating tank 18 for accommodating the cleaning liquid at the outlet side of the liquid supply needl...

Embodiment 2

[0040] The present embodiment is further limited on the basis of embodiment 1, as Figure 1 to Figure 2 As shown, as a person skilled in the art, the above accommodating tank 18 can not only form a cleaning environment for the surface of the liquid filling needle 13, but also can accommodate the corresponding cleaning liquid through a larger cross-sectional area than the straight hole, reducing the first hole section 19 is the pressure of the cleaning liquid at the position where the second hole section 20 meets, but in actual use, since the surface of the liquid feeding needle 13 needs to be cleaned using the above cleaning environment, the final liquid condition in the storage tank 18 is that there is a section The liquid column, in order to ensure the capacity of the accommodation tank 18 and reduce the static pressure generated by the liquid column at the position where the second hole segment 20 meets the first hole segment 19, is set as: the first The hole section 19 als...

Embodiment 3

[0043] The present embodiment is further limited on the basis of embodiment 1, as Figure 1 to Figure 2 As shown, in order to facilitate processing, it is set that: the first hole section 19, the second hole section 20, and the sinkhole section 21 are all straight hole sections.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com