System for monitoring unmanned aerial vehicle personnel in blasting construction site and using method

A technology of drones and personnel, applied in data processing applications, computer components, and collaborative operation devices, etc., can solve the problems that monitoring efficiency is difficult to meet the needs of production supervision, and achieve broad application scenarios, development potential, and low cost , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

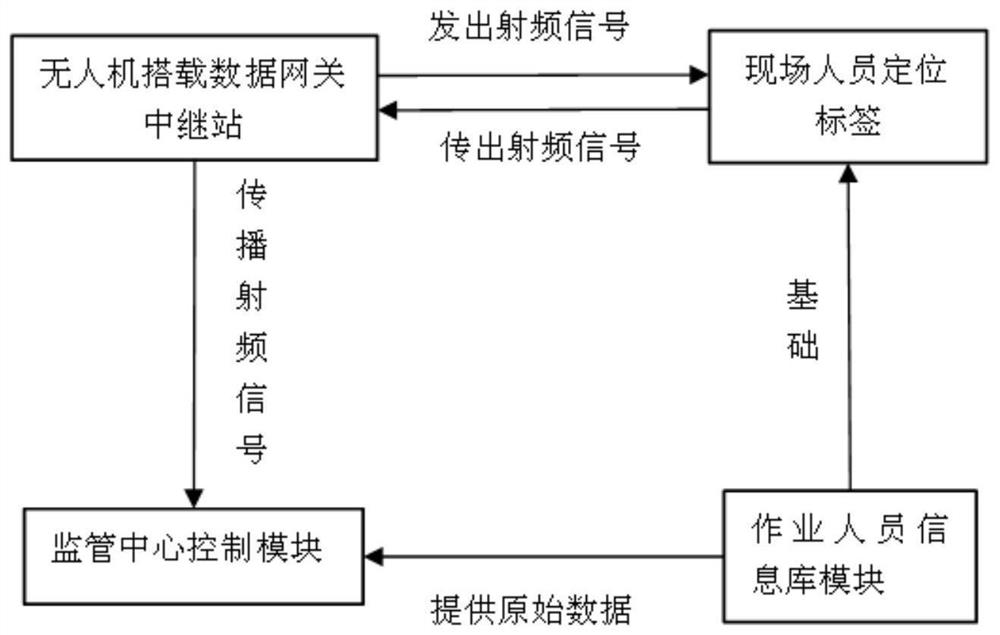

Method used

Image

Examples

Embodiment 1

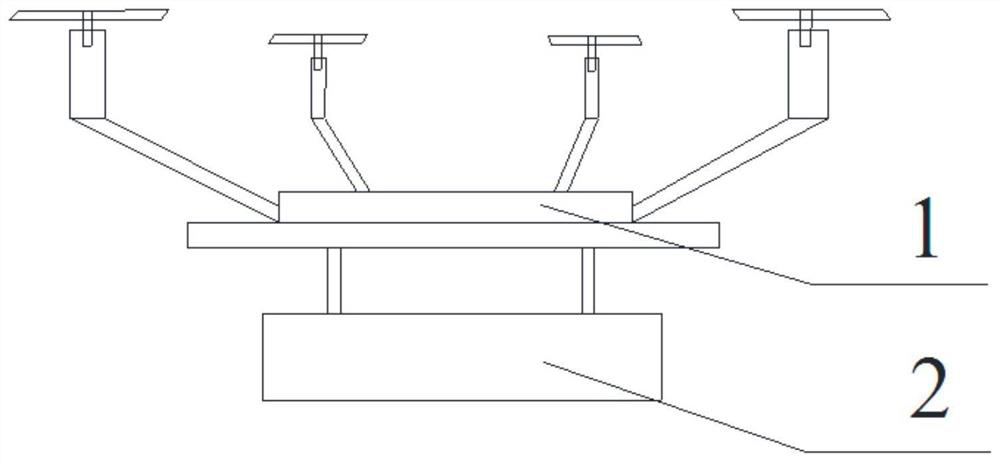

[0036] The test site is open-pit mine blasting. The blasting area is 10 square kilometers. Deep hole step blasting is carried out. The step height is 12m. For the alert range, the XF-K02(A) satellite positioning card is selected as the identification card worn by personnel, the DJI M600 UAV is selected as the carrying model, and the XF-W005(R) LORA dedicated data gateway is selected to be carried to the unmanned on board.

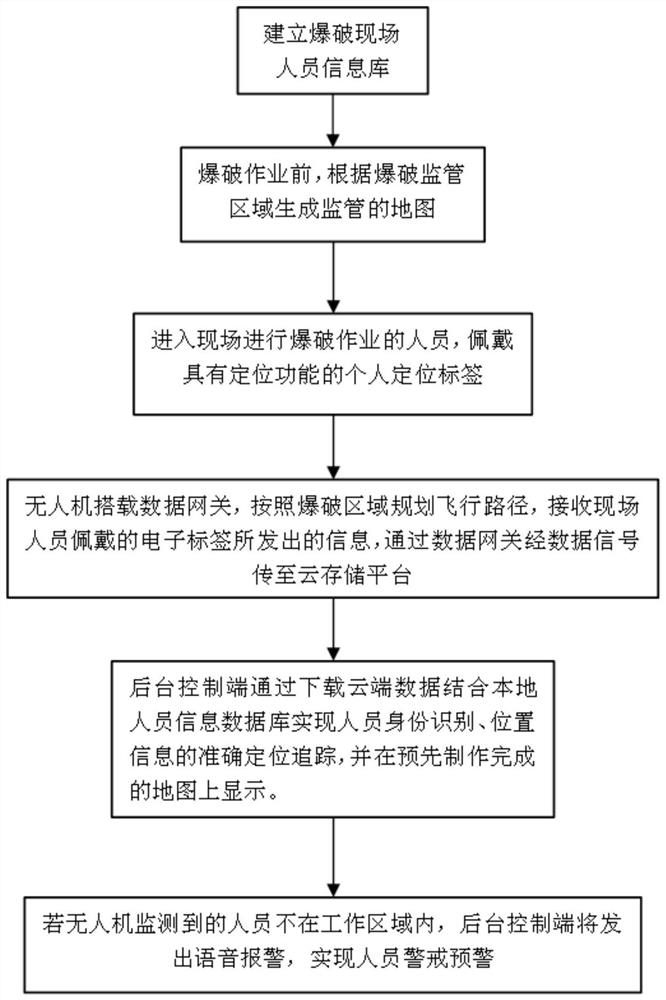

[0037] Concrete process implementation steps are as follows:

[0038] (1) Classify and count the basic information of all relevant personnel entering the blasting site, such as construction, management, and technology, establish a personnel information database at the blasting operation site according to their functions, and match the card number of the personnel identification card with the personnel information to form a card for one person collocation system.

[0039] (2) Before the blasting operation, collect the area area of the upcoming constructi...

Embodiment 2

[0045]The test site is open-pit mine blasting. The blasting area is 10 square kilometers. Deep hole step blasting is carried out. The step height is 10m, the hole spacing is designed to be 4m, and the row spacing is 3m. The blasting site is the center, and the surrounding 200m is blasting warning In terms of scope, the TK1102 satellite positioning card is selected as the identification card worn by personnel, the Yuanhang ZD550 UAV is selected as the carrying model, and the F8L10GW-L LORA dedicated data gateway is selected to be carried on the UAV.

[0046] Concrete process implementation steps are as follows:

[0047] (1) Classify and count the basic information of all relevant personnel entering the blasting site, such as construction, management, and technology, establish a personnel information database at the blasting operation site according to their functions, and match the card number of the personnel identification card with the personnel information to form a card for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com