Wafer expanding device, wafer expanding apparatus and wafer processing method

A device and wafer technology, applied in the manufacturing of electrical components, electrical solid-state devices, semiconductor/solid-state devices, etc., can solve the problems of film peeling, uneven chip spacing, unfavorable chip operation, etc., to increase stability and simplify extension control. Steps, the effect of increasing the flexibility of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, the present invention will be described in more detail with reference to the accompanying drawings. In the various drawings, the same elements are denoted by the same or similar reference numerals. For the sake of clarity, various parts in the drawings have not been drawn to scale. Also, some well-known parts may not be shown. For the sake of simplicity, the semiconductor structure obtained after several steps can be described in one figure.

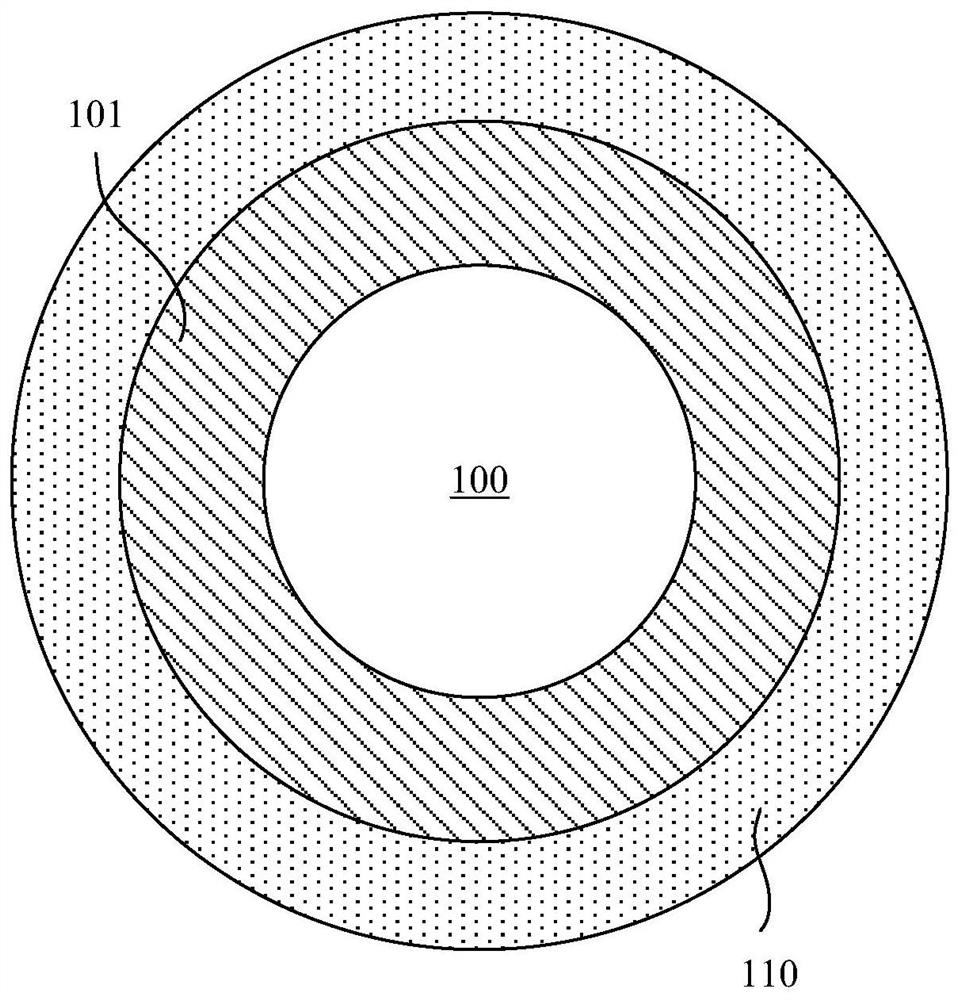

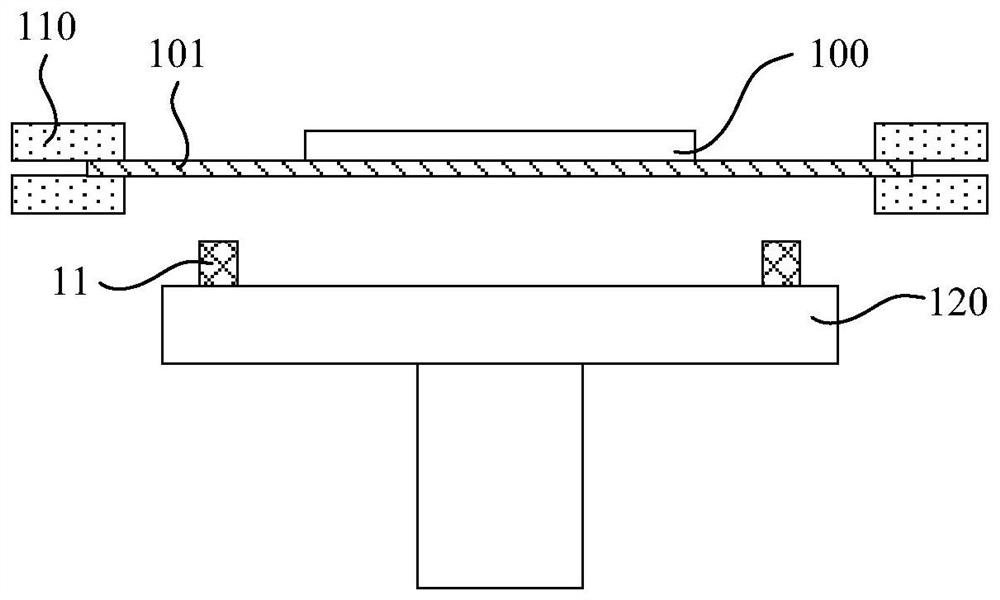

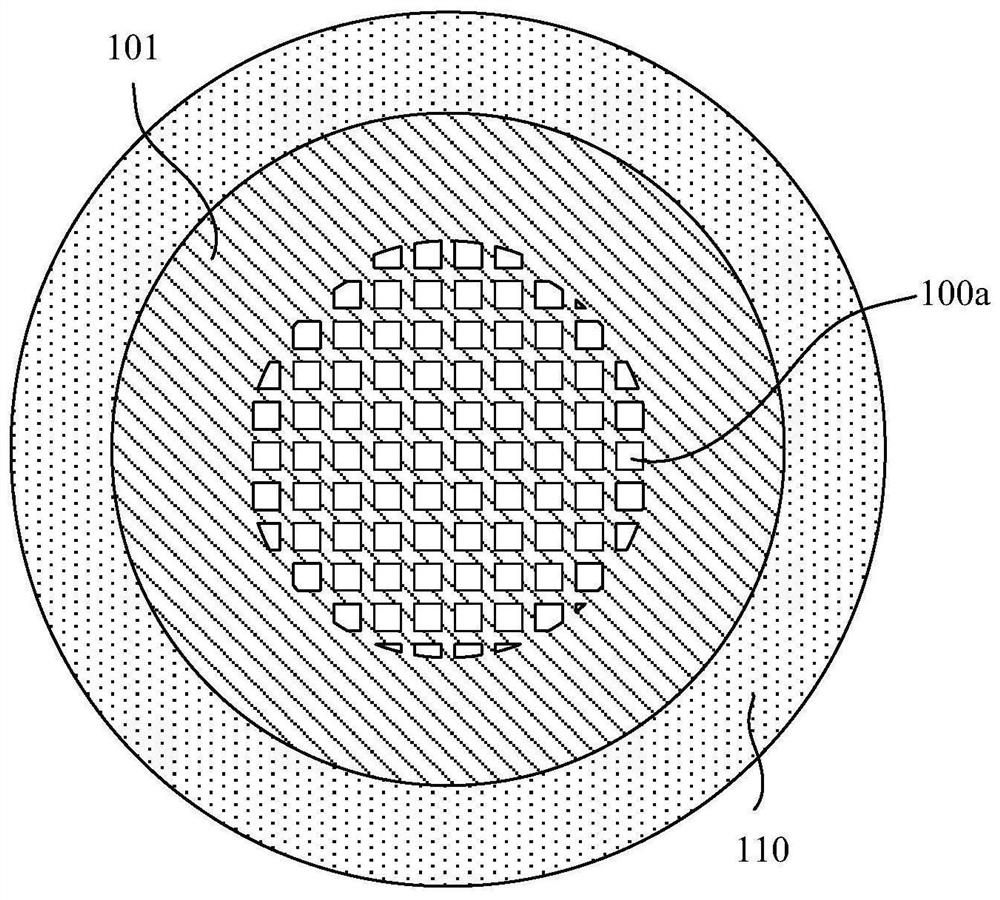

[0030] Figure 1a to Figure 4b is a schematic diagram of some stages of the wafer processing method in the related process, wherein, Figure 1a for Figure 1b top view of the Figure 2a for Figure 2b top view of the Figure 3a for Figure 3b top view of the Figure 4a for Figure 4b bottom view.

[0031] In the related process, the edge of the thin film 101 carrying the diced wafer 100 needs to be clamped and fixed by the clamping structure 110 first, and then the inner expansion ring 11 is placed on the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com