Electric welding machine for transformer production

A technology for transformers and electric welding machines, which is applied in the direction of transformer/coil connector, inductor/transformer/magnet manufacturing, circuits, etc. Avoid shedding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

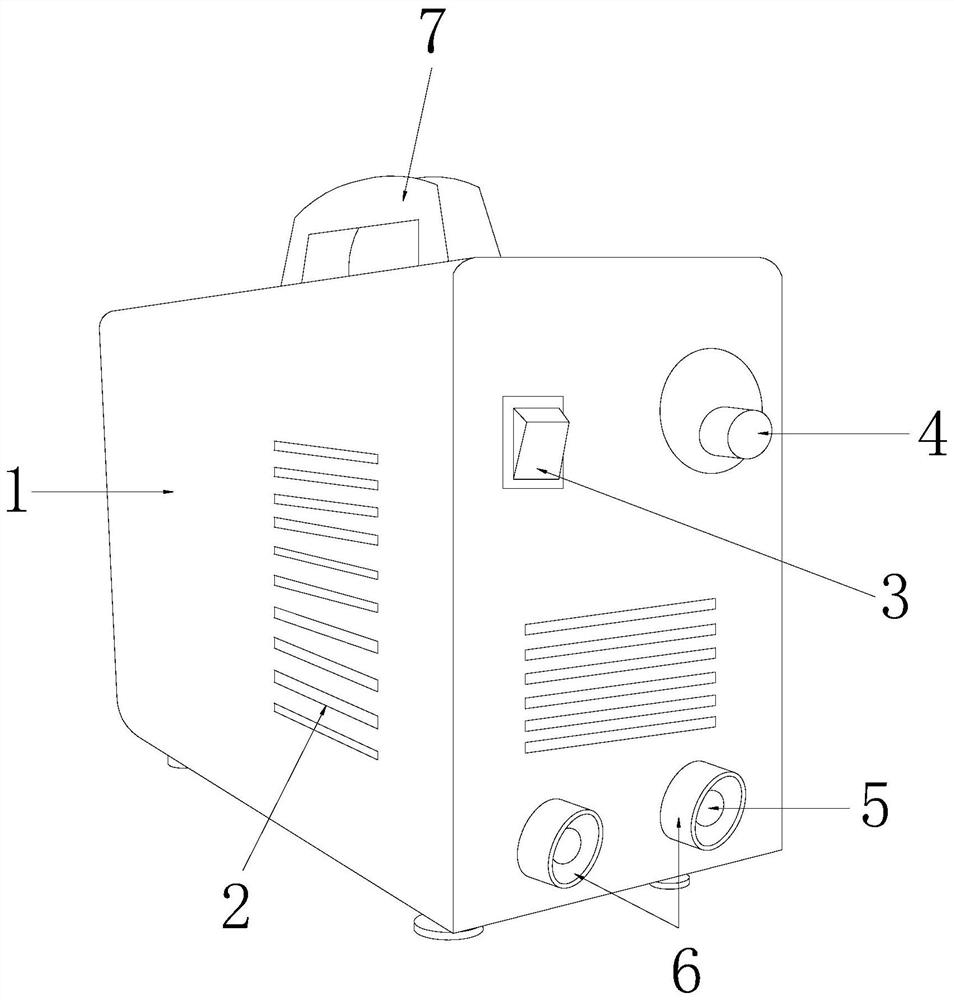

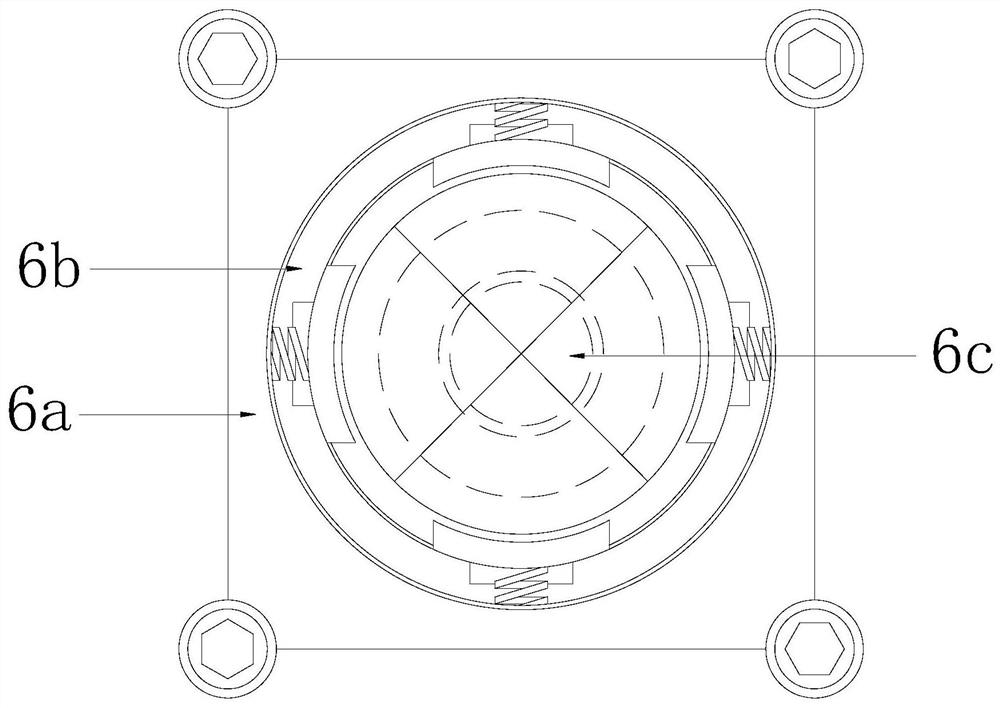

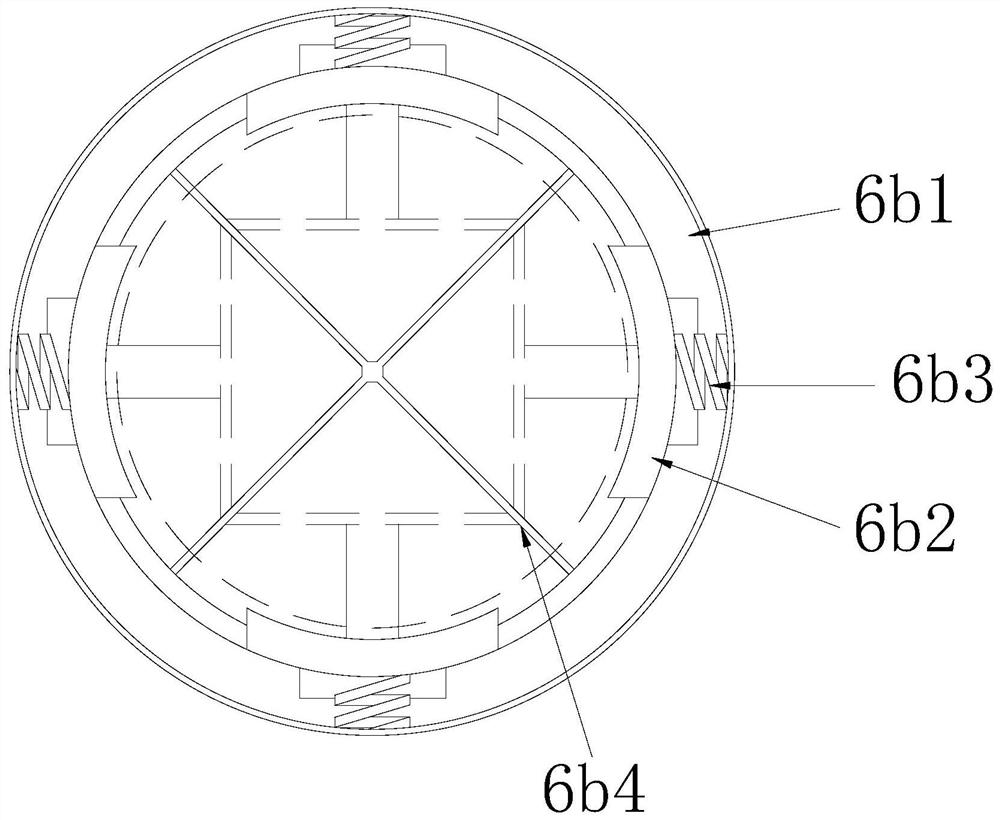

[0029] Such as Figure 1-Figure 4 As shown, the present invention provides a kind of technical scheme of electric welding machine for transformer production:

[0030] Such as Figure 1-Figure 2 As shown, an electric welding machine for transformer production has a structure including a device main body 1, a heat dissipation port 2, a switch part 3, an adjustment button 4, a connection port 5, and a protective cover 6. The heat dissipation port 2 is arranged on the front surface of the device body 1 and the left side surface, the switch part 3 is arranged on the upper part of the front surface of the device main body 1 and is electrically connected, the adjustment button 4 is arranged on the right side of the switch part 3, and the connection ports 5 are provided with two and are flush with each other. installed in the lower part of the front surface of the device main body 1, the connecting port 5 is electrically connected to the device main body 1, and the protective cover 6...

no. 2 example

[0037] Such as figure 1 , figure 2 , Figure 4 , Figure 5 , Figure 6 As shown, the present invention provides a kind of technical scheme of electric welding machine for transformer production:

[0038] Such as Figure 1-Figure 2As shown, an electric welding machine for transformer production has a structure including a device main body 1, a heat dissipation port 2, a switch part 3, an adjustment button 4, a connection port 5, and a protective cover 6. The heat dissipation port 2 is arranged on the front surface of the device body 1 and the left side surface, the switch part 3 is arranged on the upper part of the front surface of the device main body 1 and is electrically connected, the adjustment button 4 is arranged on the right side of the switch part 3, and the connection ports 5 are provided with two and are flush with each other. installed in the lower part of the front surface of the device main body 1, the connecting port 5 is electrically connected to the devi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap