Washing machine handle injection mold

A technology for injection molds and washing machines, which can be applied to household appliances, other household appliances, household components, etc., can solve problems such as uneven wall thickness, and achieve the effects of improving product quality, improving production efficiency and yield, and directional change state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

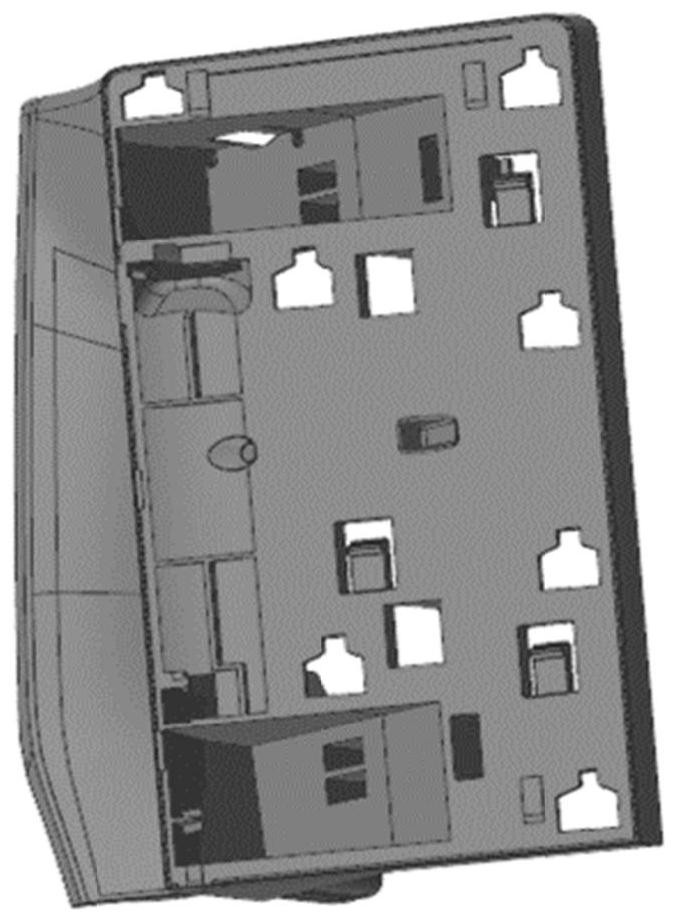

Image

Examples

Embodiment 1

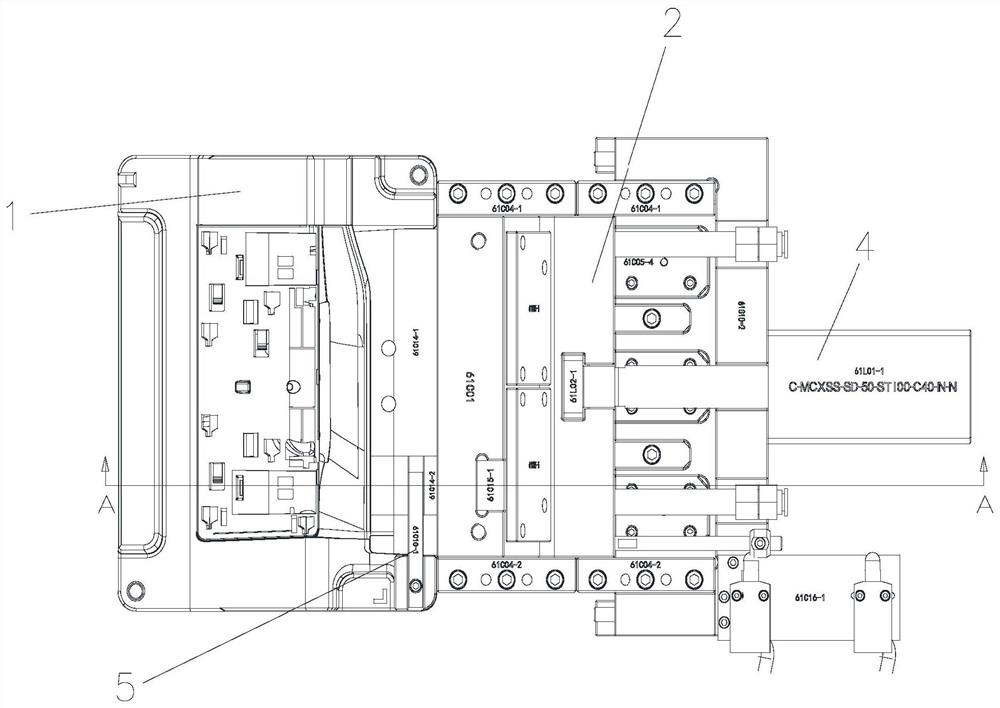

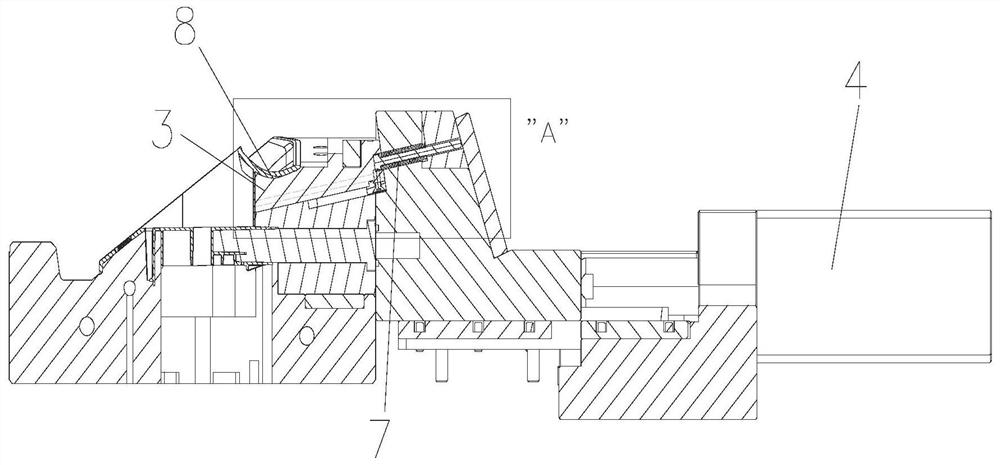

[0044] In this embodiment, the injection mold for the handle of the washing machine includes an upper mold and a lower mold 1, and the lower mold 1 is provided with a first slider 2, a second slider 3 and a first stopper 5, see figure 2 , Figure 5 and Figure 8 , the upper surface of the head of the first slider 2 is an inclined plane, the lower surface of the second slider 3 is an inclined plane matching the upper surface, and one end of the upper surface of the second slider 3 is provided with a limiting groove, and the upper surface The other end of the surface matches the arc surface of the lower surface of the washing machine handle 8, see Figure 4 , Figure 7 , Figure 10 and Figure 11 , the first limit block 5 is clamped in the limit groove when the mold is closed, so as to realize the horizontal limit of the second slider 3, see image 3 and Figure 4 .

[0045] The first limiting block 5 is fixedly connected to the mold 1 and is located on the upper surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com