Methanol-to-olefin quenching and washing water micro-bubble pressurized flotation purification device and method

A technology for methanol to olefins and flotation devices, which is applied in chemical instruments and methods, grease/oily substance/float removal devices, separation methods, etc. Waxing etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

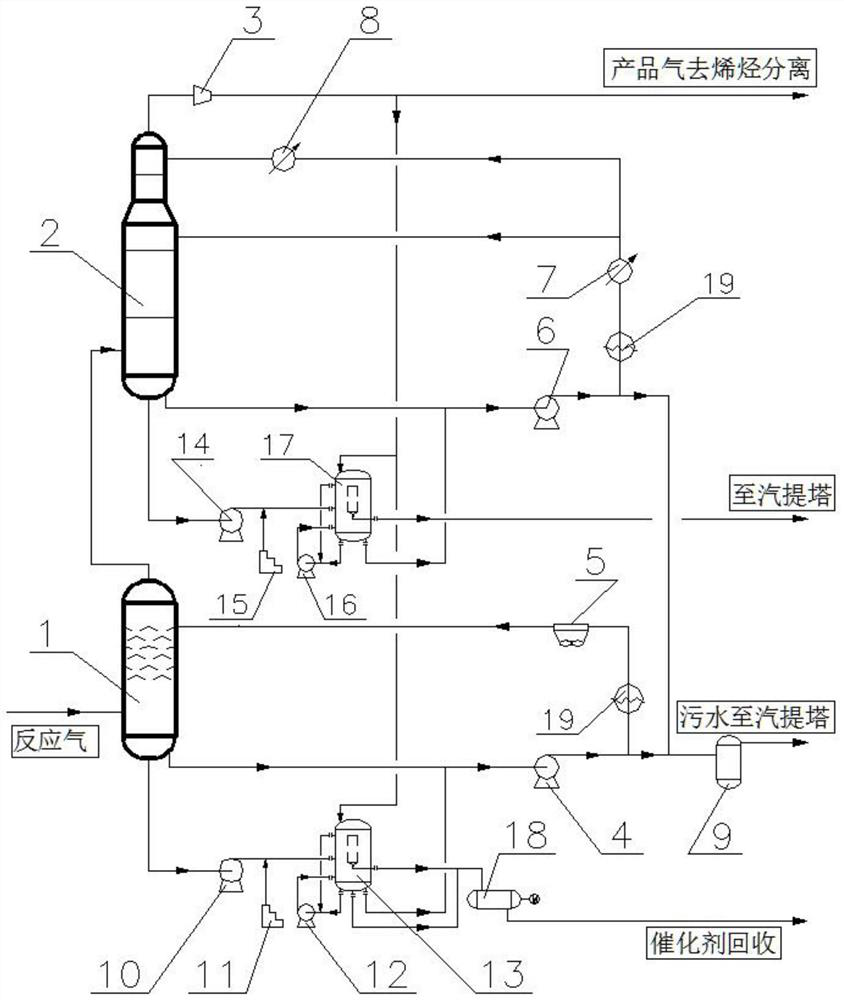

[0047] The quenching water at the bottom of the quenching tower and the washing water at the bottom of the washing tower in a methanol-to-olefins process are treated according to the method of the present invention, and the device and method of the present invention are used to treat the catalyst and pollution in the quenching water and washing water in the methanol-to-olefins process. The problem of oil removal and fouling of quench tower, water washing tower and heat exchanger can improve the operation cycle of methanol to olefins equipment, reduce cleaning costs, improve the heat utilization efficiency of the system and water recycling rate, and reduce sewage discharge.

[0048] In a methanol-to-olefins process, according to the device and method of the present invention, a treatment device for micro-bubble pressurized swirl flotation of methanol to olefins is used: (a) the quenching water at the bottom of the quenching tower and the washing water at the bottom of the washing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap