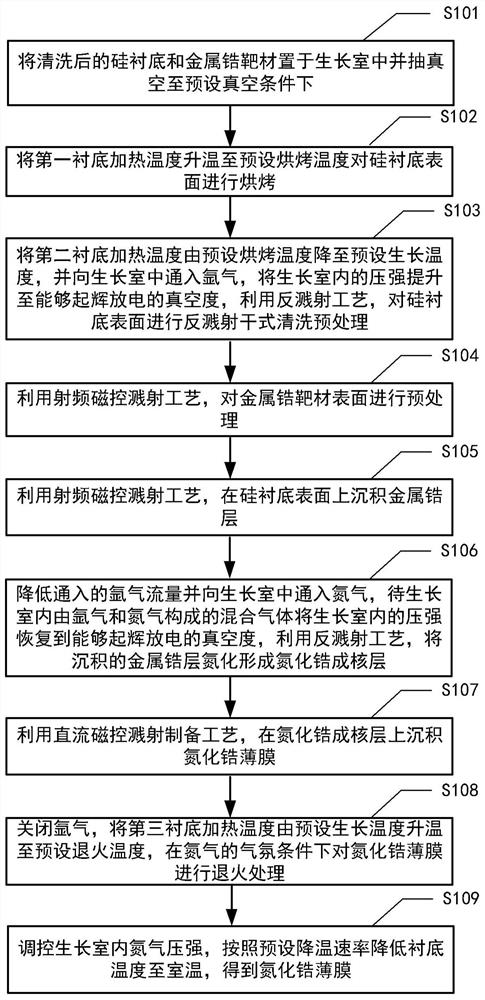

Method for preparing zirconium nitride thin film on silicon substrate by magnetron sputtering

A magnetron sputtering and radio frequency magnetron sputtering technology, applied in chemical instruments and methods, from chemical reactive gases, single crystal growth, etc. Problems such as the report of thin film growth results, to achieve the effect of good application and promotion value, small surface undulation, growth rate and film formation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

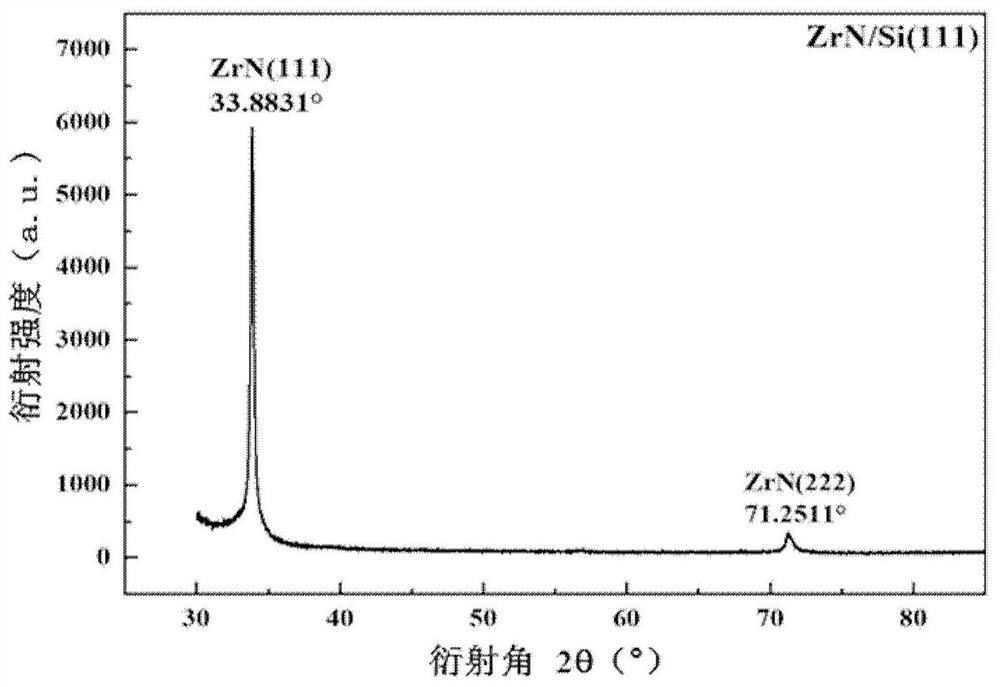

[0022] At present, due to the slow growth rate of silicon nitride deposition prepared by atomic layer deposition, although high-purity ZrN films with nanoscale thickness can be prepared, due to the low growth temperature, only amorphous or polycrystalline materials with poor crystalline quality can be grown; MOCVD process The preparation and growth of ZrN thin films is still in research and development, and there is no high-quality single-crystal thin film that can realize the X-ray rocking curve (XRC) of the ZrN (111) diffraction peak on Si substrates to reduce the full width at half maximum (FWHM) to less than 1°. The growth results are reported; Ion beam epitaxy (IBE) process achieves highly single-preferred orientation growth of ZrN thin films, but due to the small film formation area (2cm×2cm) of ion beam epitaxy process, it is not suitable to use the existing semiconductor device technology to fabricate devices.

[0023] Magnetron sputtering is still the main process for ...

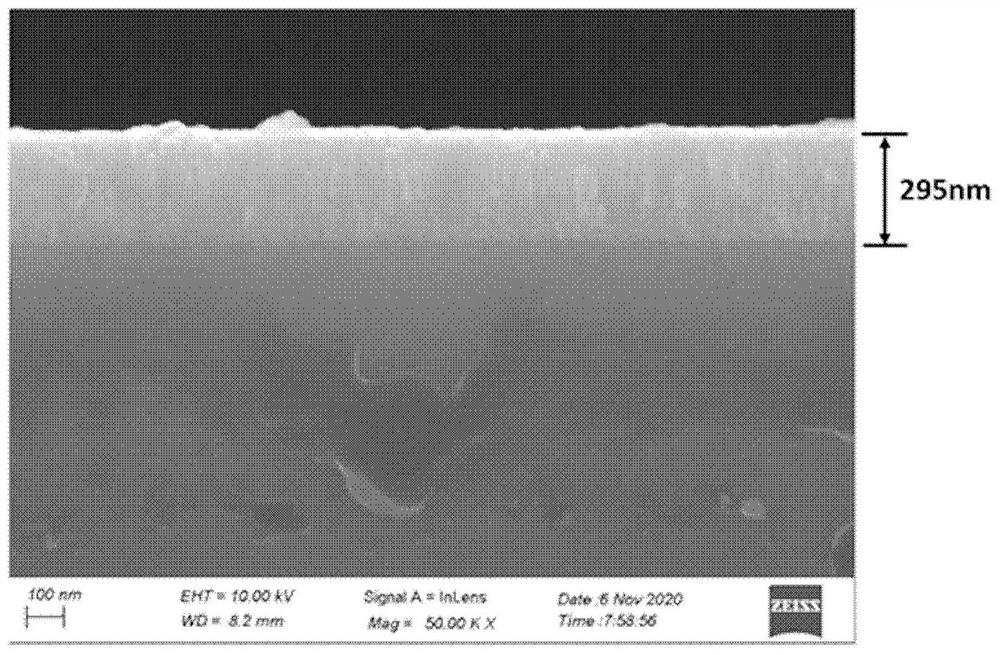

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com