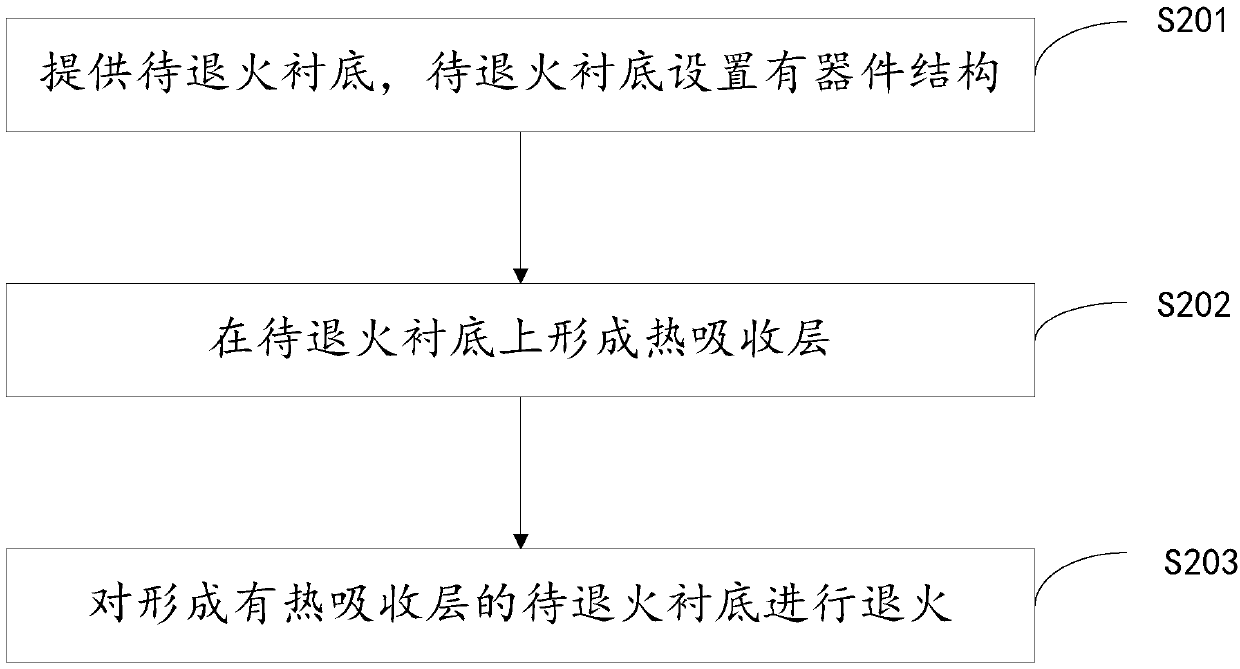

Annealing method

A technology of annealing and annealing treatment, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of uneven heat absorption efficiency, uneven heat distribution, uneven device performance, etc., to improve device performance uniformity and heat distribution. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

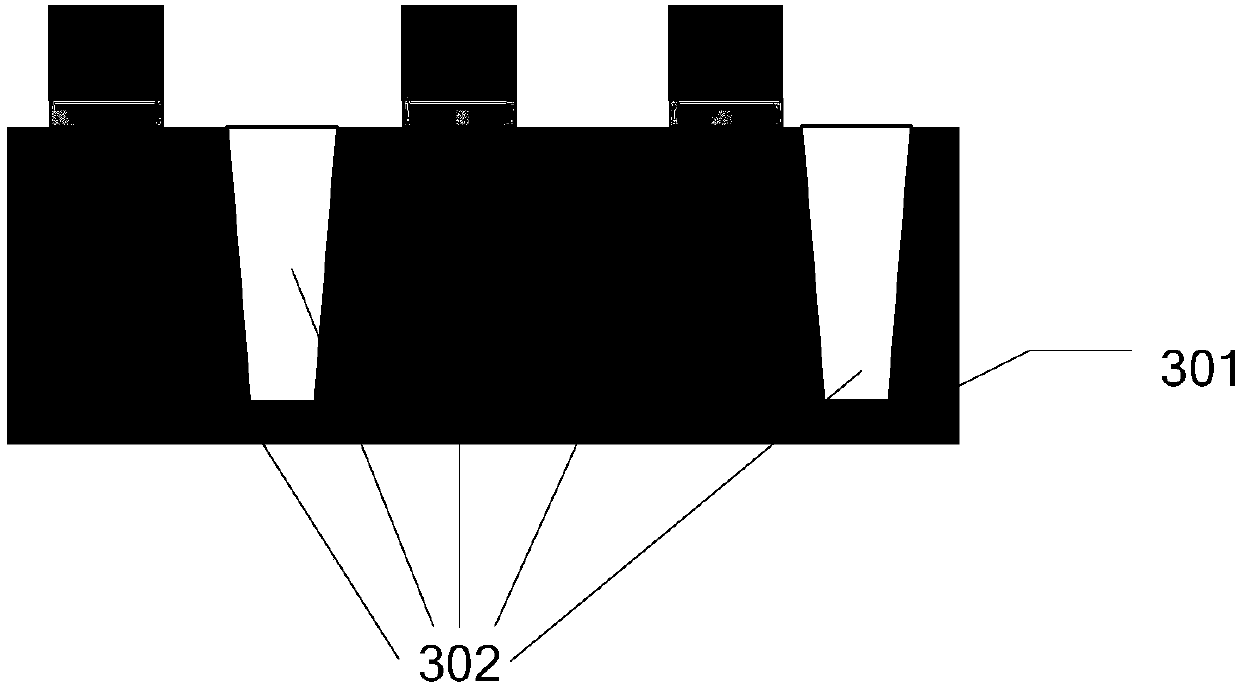

Embodiment Construction

[0029] A semiconductor is a substance whose conductivity is between that of a conductor and an insulator. In order to make semiconductor materials form PN junctions (the material basis of diodes and triodes), resistors, and interconnect lines in semiconductor devices, it is often necessary to change the electrical properties of the materials through doping.

[0030] Doping can be understood as adding the required impurities into the semiconductor material according to the required concentration and distribution. Doping can generally be achieved by diffusion or ion implantation. Generally, thermal diffusion is used for high-concentration deep junction doping, and ion implantation is used for shallow junction high-precision doping. Ion implantation can strictly control the doping amount and distribution, and has the characteristics of low doping temperature, less lateral diffusion, and more dopant elements. It can dope various materials, and the impurity concentration is not li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com