A passive preloaded maglev turnout main beam vibration suppression structure

A passive, turnout technology, applied in the directions of roads, tracks, buildings, etc., can solve the problems of limited vibration control frequency band and complex structure, achieve the effect of effective frequency bandwidth, improve the force of the turnout, and strengthen the connection stiffness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

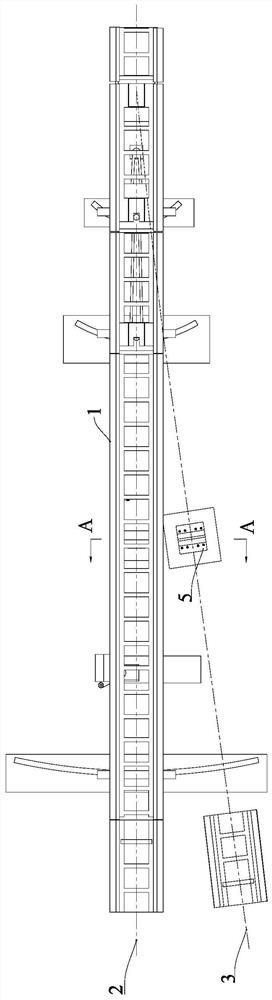

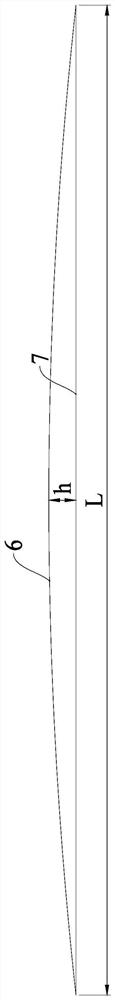

[0034] like Figure 1-Figure 2 As shown in the figure, a passive preloading type maglev turnout main beam vibration suppression structure includes a turnout main girder 1 and a passive preloading mechanism. The maximum value of the pre-camber is h under the working condition without vehicle load), and the pre-camber line 6 is as follows image 3 shown, image 3 The middle 7 is the horizontal line. The precamber h is greater than 150% of the vertical deflection of the track beam under the maximum load of the train.

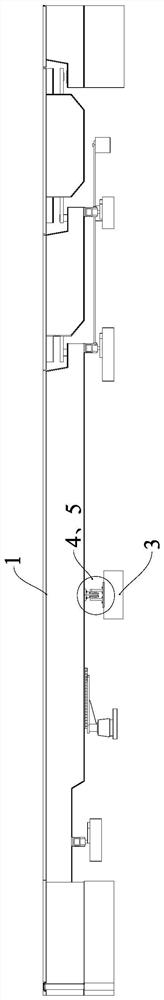

[0035] like Figure 4-Figure 5 As shown, the passive preloading mechanism in this embodiment includes a first structure 4 and a second structure 5, the first structure 4 is fixedly connected under the main beam 1 of the turnout, and the second structure 5 is respectively arranged on the forward position foundation 2 and the side The orientation base 3 and the second structure 5 are fixedly connected above the track base (the forward base 2 and the lateral base ...

Embodiment 2

[0041] like Image 6 As shown, the difference between this embodiment and Embodiment 1 is that the second structure 5 is fixedly connected under the main beam 1 of the turnout, and the first structure 4 is fixedly connected to the track foundation (the forward position foundation 2 and the lateral position foundation 3) above.

Embodiment 3

[0043] like Figure 7 As shown, the difference between this embodiment and Embodiment 1 is that an elastic connecting member 8 is connected between the first mounting seat 41 and the rolling device 42 . The elastic connector 8 may be a spring or other elastic element.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com