Floor system structure composed of assembly boxes

A technology for assembling boxes and floors, which is applied to floors, building components, building structures, etc. It can solve the problems of difficult assembly construction, difficult maintenance of assembly components, modularization, unitization, inconvenient installation, laying, inspection and repair, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

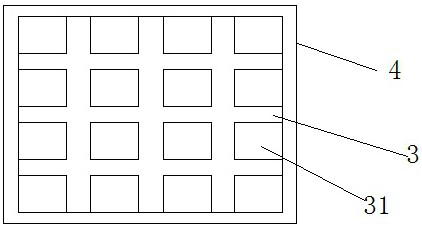

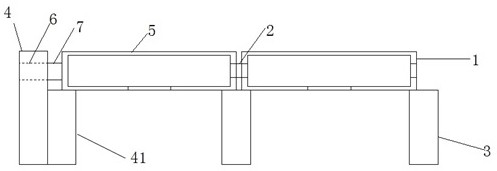

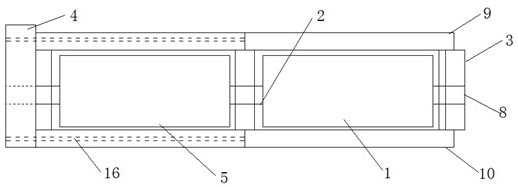

[0041] Such as figure 1 and Figure 4 As shown, a floor structure composed of assembly boxes includes an assembly box array composed of a plurality of assembly boxes 1, and interconnecting pipes 2 are connected between adjacent assembly boxes 1 in the assembly box array. Pipelines are laid in the box array, and the pipelines can be smoke exhaust pipelines, fire-fighting pipelines, ventilation pipelines, etc. There are well-shaped beams 3 arranged in the gaps of the assembly box arrays, and a plurality of assembly boxes 1 are respectively connected to a plurality of well-shaped beams 3. The beam grids 31 correspond one by one, and the outer frame beam 4 fixedly connected with the well-shaped beam 3 is arranged on the periphery of the assembly box array, and the multiple peripheral assembly boxes 5 located on the periphery of the assembly box array are all connected to the web of the outer frame beam 4 , the web of the outer frame beam 4 is provided with a pipe outlet 6 corresp...

Embodiment 2

[0050] The cross-sectional shapes of the well-shaped beam 3 and the outer frame beam 4 can be hollow rectangular beams, T-shaped beams and I-shaped beams. The present invention uses I-shaped beams as an example to focus on description below.

[0051] Such as Figure 5 As shown, the beam structures of the outer frame beam 4 and the well-shaped beam 3 are I-beams, and the edge of the bottom plate of the assembly box 1 is installed above the upper flange of the corresponding I-beam, and the bottom plate of the assembly box 1 and the The upper flange is fixedly connected by bolts.

[0052] Such as Figure 6 and Figure 7 As shown, the edge of the assembly box 1 is embedded in the groove formed by the web, upper flange and lower flange of the I-beam, the top plate 17 of the assembly box 1 is horizontally aligned with the upper flange of the I-beam, and the top plate 17 The edge of the edge is provided with the step that is sunken to the board, the height of the step is consisten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com