Drill jumbo lighting and camera shooting follow-up system, control method and drill jumbo

A rock drilling jumbo and servo system technology, applied to drilling equipment and methods, TV system components, earthwork drilling and mining, etc., can solve problems such as poor lighting and camera effects, increase the workload of operators, etc., and achieve Effects of improving work efficiency and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings, wherein the terms "first", "second", "third" and the like are only used for description purposes, and cannot be understood as indicating or implying relative importance.

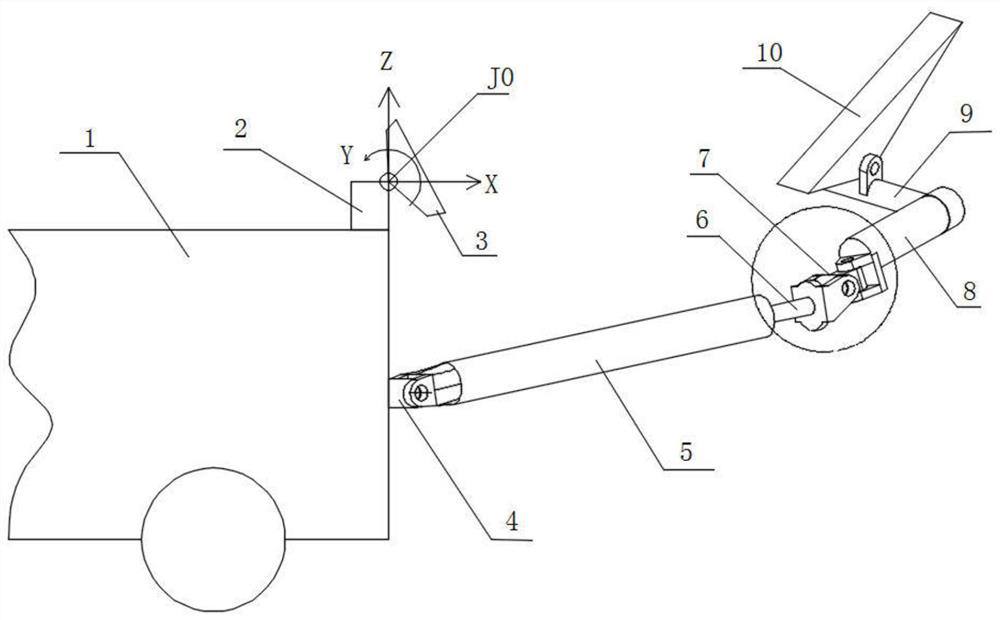

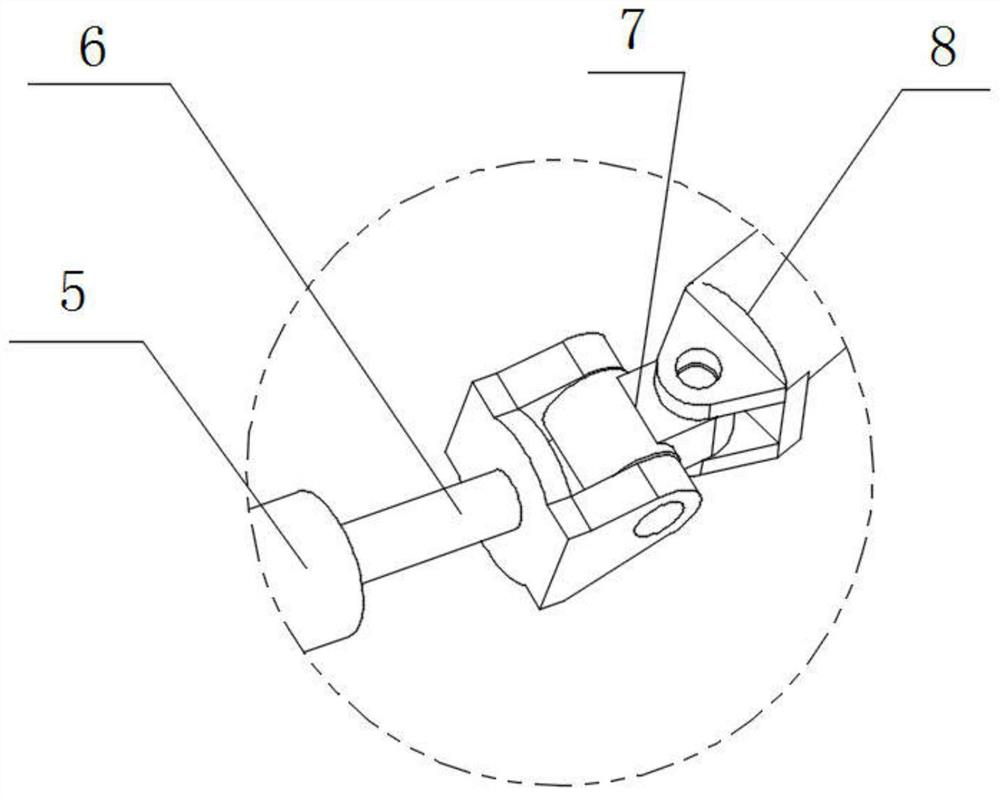

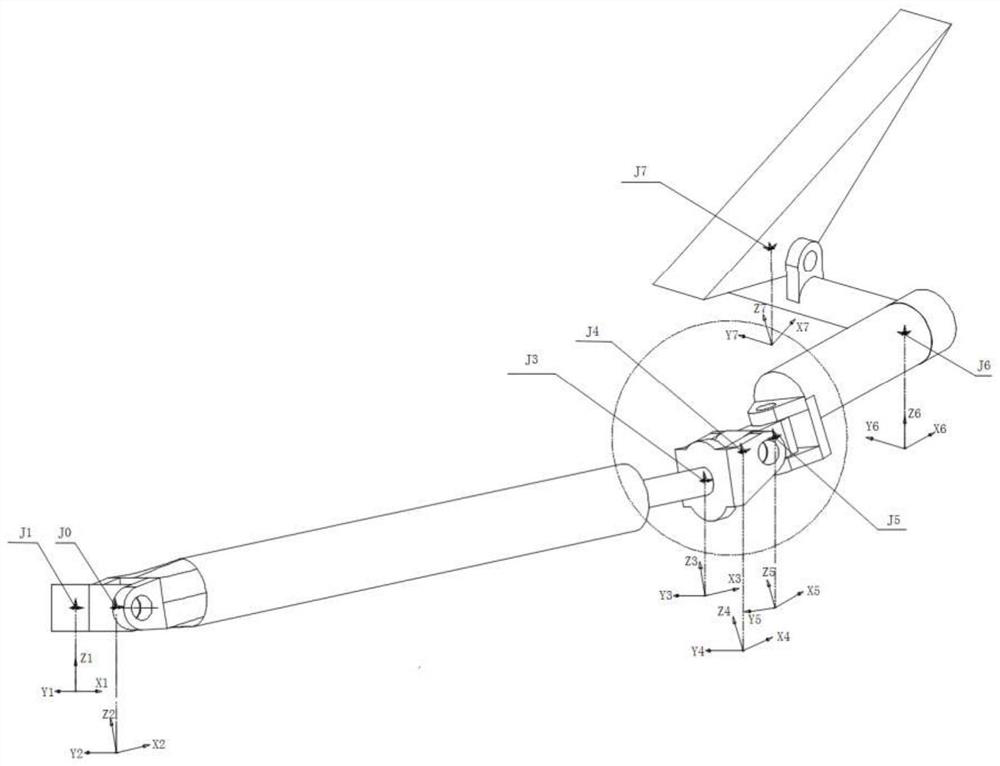

[0063] combine figure 1 As shown, the lighting camera follow-up system of the present invention includes a vehicle frame 1, a rock drilling work assembly arranged on the vehicle frame 1, a cloud platform 2 and a control device, and the cloud platform 2 is provided with an illumination camera device 3, the drilling The rock working assembly is provided with a rock drill 11 . The cloud platform 2 is used to install, fix and support the lighting camera device 3, and the motor can be used to adjust the horizontal and pitch angles of the lighting camera device 3. Usually, the lighting direction and the camera direction are the same, so they are arranged on the same cloud platform 2. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com