Waterwheel oil cylinder for environmental sanitation machinery

An oil cylinder and mechanical technology, applied in the field of sanitation machinery water tanker oil cylinder, can solve the problems of no supporting heat dissipation measures, no protection measures for hydraulic rods, etc., and achieve the effects of reducing contact, protecting the working environment and reducing wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

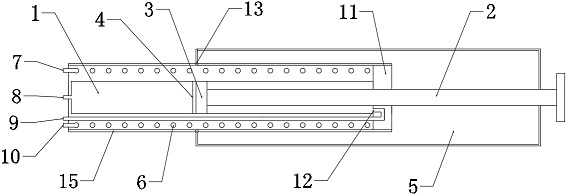

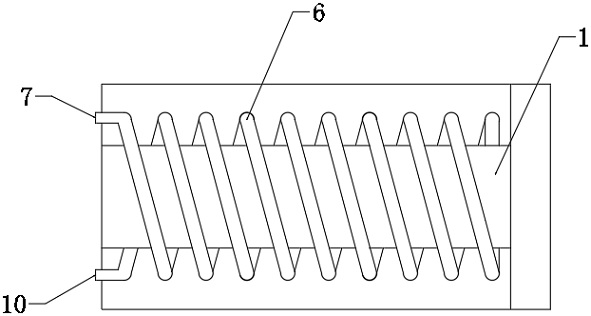

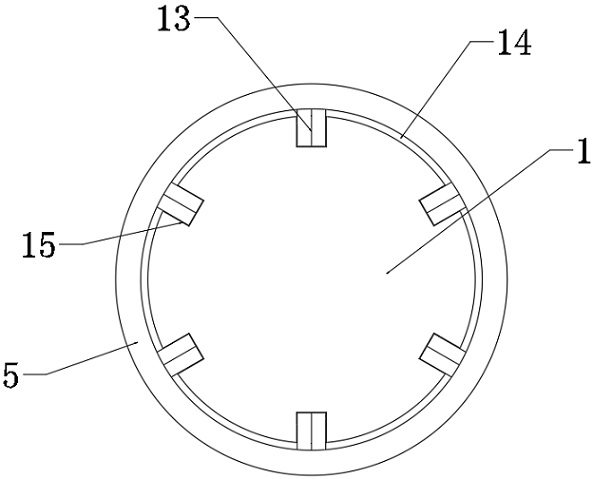

[0022] A sanitation mechanical water wheel oil cylinder, in order to facilitate heat dissipation and protect the hydraulic rod, as a preferred embodiment, such as figure 1 , figure 2 As shown, it includes cylinder body 1, hydraulic rod 2 and cylinder head 11. The top of oil cylinder body 1 is fixed with cylinder head 11 by bolts, the middle part of cylinder head 11 is provided with hydraulic rod 2, and the lower part of hydraulic rod 2 is fixed with piston 3 by bolts. The end of 3 is provided with shock absorbing device 4, the top of hydraulic rod 2 is welded with protective cover 5, protective cover 5 is cylindrical, and the inside of protective cover 5 is hollow structure, the bottom of protective cover 5 is provided with pulley 14, and the outside of oil cylinder body 1 is provided with The groove 15, the pulley 14 is slidingly connected with the groove 15, the lower oil inlet hole 8 is provided at the center of the bottom of the oil cylinder body 1, and the upper oil inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com