A kind of carbon nanotube and its preparation method and application

A technology of carbon nanotubes and transition metal salts, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of unfavorable industrial production, small diameter of carbon nanotubes, cumbersome preparation process, etc. Achieve great application value, low cost, and simplify the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a method for preparing carbon nanotubes, comprising the following steps:

[0029] Ball milling transition metal salts, phenolic compounds and non-ionic block copolymers to obtain gel-like precursor materials;

[0030] The gel precursor material is carbonized in a protective atmosphere, and then washed to obtain carbon nanotubes.

[0031] In the invention, the transition metal salt, the phenolic compound and the non-ionic block copolymer are ball-milled to obtain a gel precursor material.

[0032] In the present invention, the transition metal salt preferably includes at least one of cobalt salt, nickel salt, zinc salt, iron salt, ferrous salt, manganese salt and copper salt; specifically, the cobalt salt preferably includes anhydrous Cobalt Chloride, Cobalt Chloride Dihydrate, Cobalt Chloride Hexahydrate, Cobalt Nitrate Anhydrous, Cobalt Nitrate Hexahydrate, Cobalt Sulfate Anhydrous, Cobalt Sulfate Monohydrate, Cobalt Sulfate Hexahydrate, Cobalt ...

Embodiment 1

[0044] Weigh 0.5g cobalt chloride hexahydrate, 0.75g tannic acid and 2g F127, and ball mill for 4h at a speed of 200rpm to obtain a gel-like precursor material; 2 In the atmosphere, the gel precursor material was heated from room temperature (25°C) to 300°C at a rate of 5°C / min, kept at 300°C for 1 hour, and then heated to 800°C at a rate of 5°C / min. °C, heat preservation treatment at 800 °C for 4 hours; the obtained material was naturally cooled to room temperature, and the material was washed with hydrochloric acid with a concentration of 1mol / L, and then washed three times with distilled water to obtain carbon nanotubes.

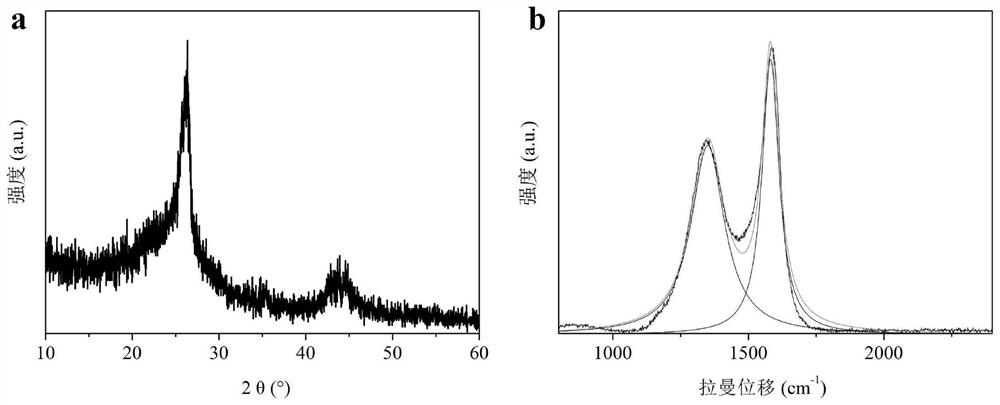

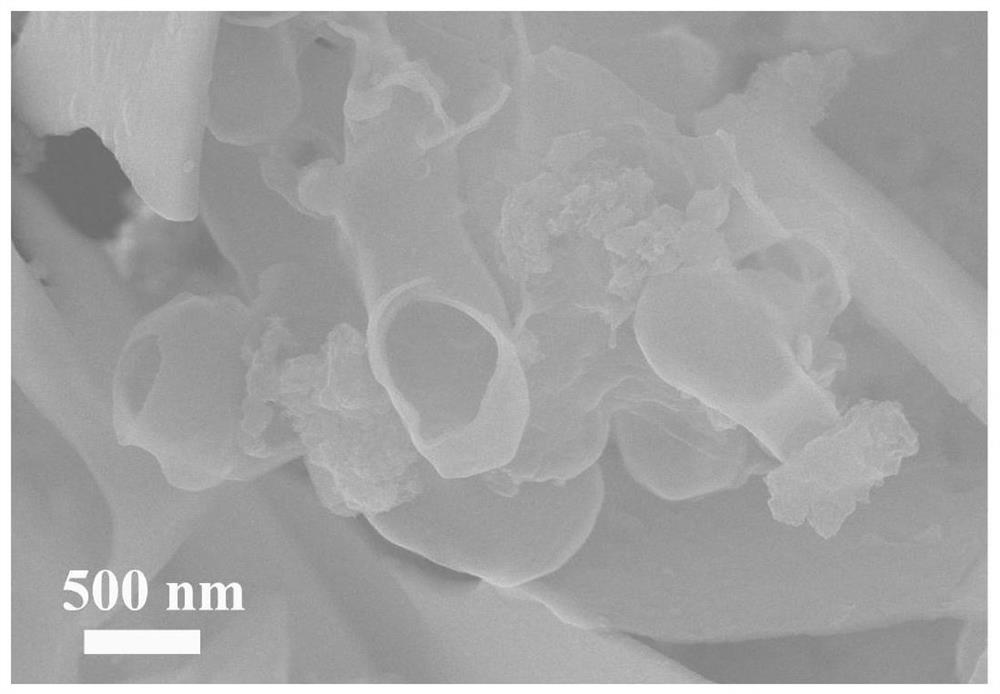

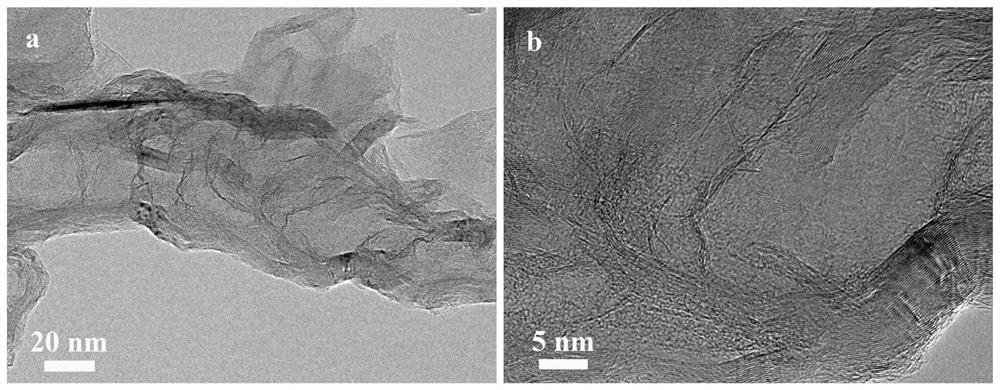

[0045] figure 1 The X-ray diffraction pattern and Raman spectrum pattern of the carbon nanotube prepared for Example 1, wherein, a is the X-ray diffraction pattern, and b is the Raman spectrum pattern. Depend on figure 1 It can be seen that the metal impurities in the carbon nanotubes have been completely removed by a in figure 1 It can be seen that th...

Embodiment 2

[0050] 0.5g of ferric chloride hexahydrate, 0.75g of tannic acid and 2g of F127 were ball-milled at 200rpm for 4h to obtain a gel-like precursor material; 2 In the atmosphere, the gel precursor material was heated from room temperature (25°C) to 300°C at a rate of 5°C / min, kept at 300°C for 1 hour, and then heated to 800°C at a rate of 5°C / min. °C, heat preservation treatment at 800 °C for 4 hours, the obtained material was naturally cooled to room temperature, the material was washed with hydrochloric acid with a concentration of 1.5 mol / L, and then washed three times with distilled water to obtain carbon nanotubes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com