High-strength steel sheet for sour-resistant line pipe, method for producing same, and high-strength steel pipe using high-strength steel sheet for sour-resistant line pipe

A technology of high-strength steel plate and manufacturing method, which is applied in the field of high-strength steel plate for acid-resistant line pipe and its manufacture and high-strength steel pipe using high-strength steel plate for acid-resistant line pipe, which can solve the problems of uneven scale thickness, deviation of steel plate material, Problems such as cooling speed deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

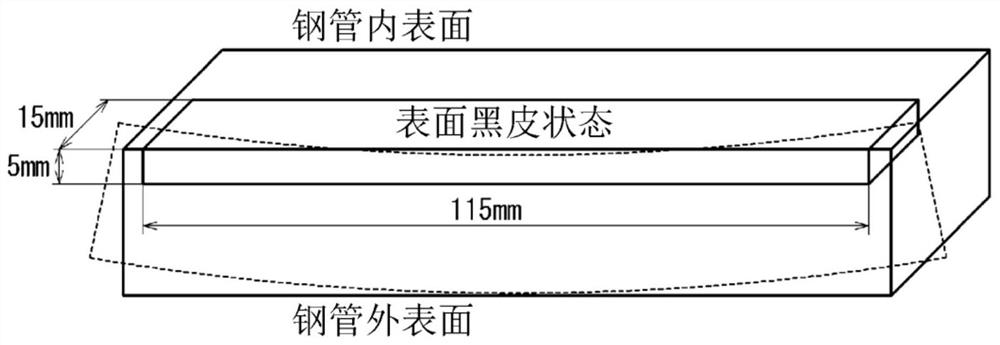

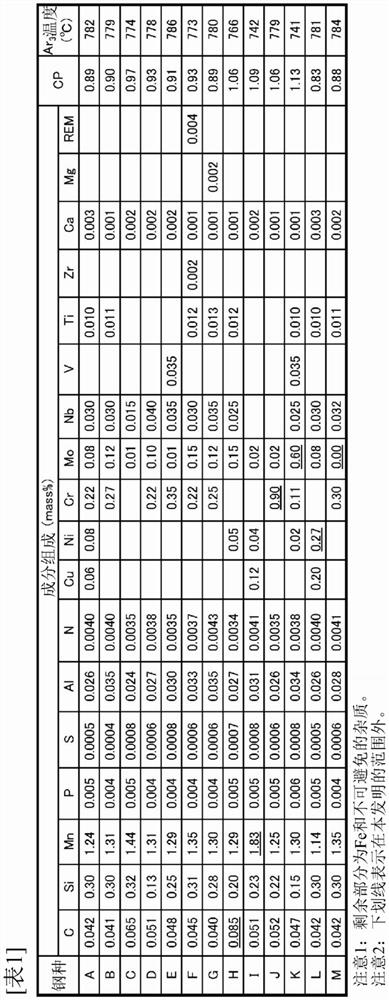

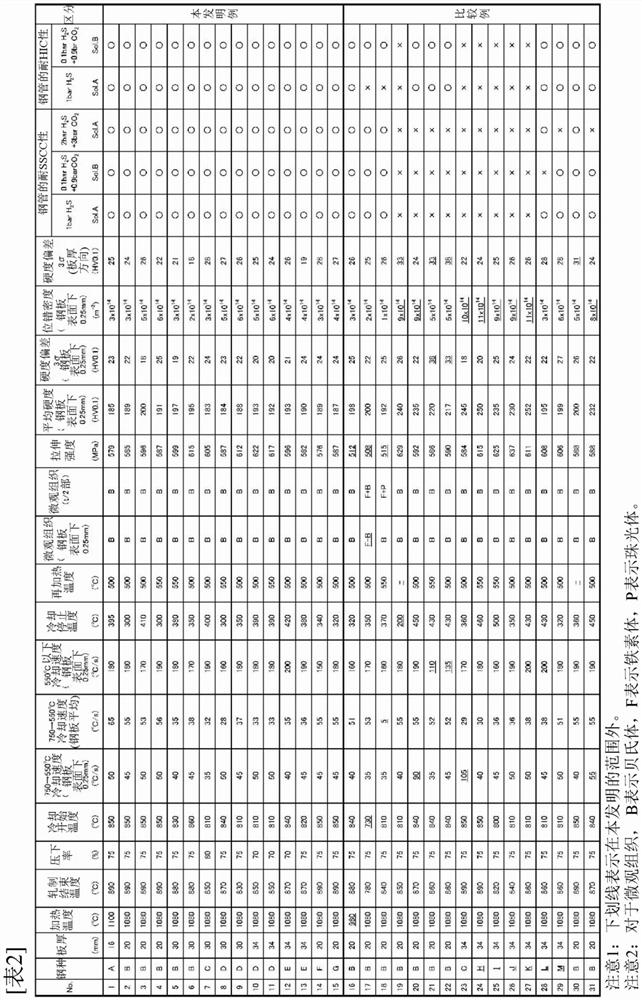

[0119] The steels (steel grades A to M) having the composition shown in Table 1 were made into slabs by continuous casting, heated to the temperature shown in Table 2, and then rolled at the end temperature and reduction shown in Table 2. Hot-rolled at a certain rate to produce steel sheets with the thicknesses shown in Table 2. Then, under the conditions shown in Table 2, the steel plates were controlled and cooled using a water-cooled controlled cooling device. Then, the steel plate was reheated immediately using the online induction heating apparatus so that the average temperature of the steel plate became "reheating temperature" of Table 2.

[0120] [determination of organization]

[0121] The microstructure of the obtained steel sheet was observed with an optical microscope and a scanning electron microscope. Table 2 shows the structure at a position 0.25 mm below the surface of the steel plate and the structure at the center of the plate thickness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| dislocation density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com