Hemp rope molding pressing equipment used for eight-strand hemp rope wheel production

A technology of hemp rope and equipment, which is applied in the direction of metal processing equipment, grinding/polishing equipment, grinding devices, etc., can solve the problems of waste of efficiency, increase of labor, etc., achieve a wide range of applications, improve processing efficiency, and bend hemp rope high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

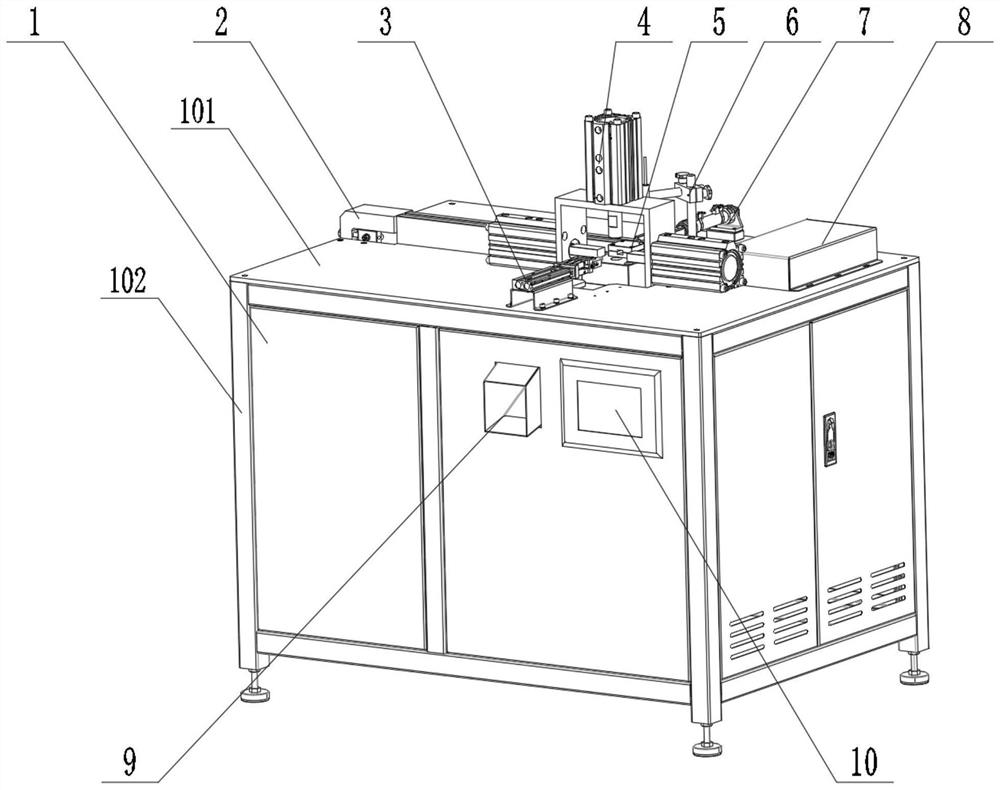

[0035] see Figure 1-6 , among the hemp rope molding equipment for producing eight-strand hemp rope wheels, a hemp rope molding equipment for producing eight-strand hemp rope wheels, including equipment box 1, conveying device 2, clamping and discharging mechanism 3, type Pressing device 4, hemp rope bending and forming guide device 5, material level detection device 6, side pushing device 7, motor shield 8, blanking port 9 and touch display screen 10.

[0036] The equipment box 1 is used as the main supporting part of the equipment, and is used to install various devices, including the platform surface 101, the main frame 102, the electrical control system, and the gas circuit control system, wherein the electrical control system is connected to the gas circuit control system, and the installation Inside the main frame 102 , the platform surface 101 is installed above the main frame 102 .

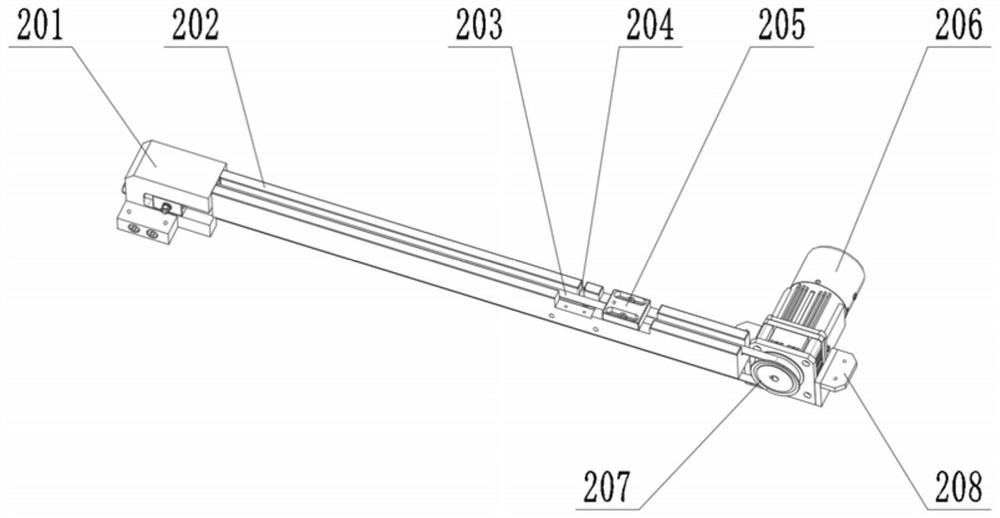

[0037]The conveying device 2 is arranged horizontally on the platform surface 101, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com