Cambered surface forming device of tongue depressor for observing throat for ophthalmology and otorhinolaryngology

A technology of forming device and tongue depressor, applied in special forming/shaping machine, forming/shaping machine, solid separation, etc., can solve problems such as safety hazards, and achieve the effect of thorough cleaning and clean surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

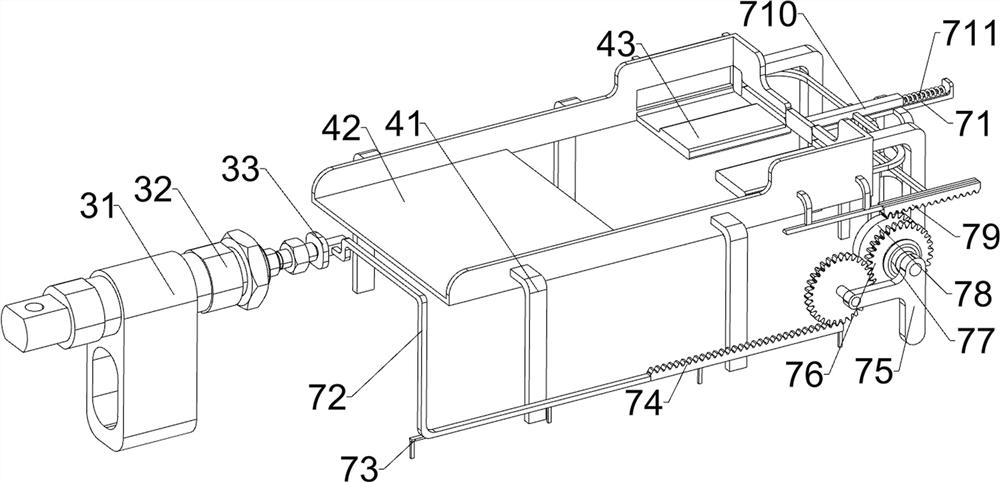

[0045]One type of five-serviced tongue arc surface molding apparatus for observing the throat, such asfigure 1 As shown, there is a bottom plate 1, a slot plate 2, a curved cutting mechanism 3, and a placed collecting mechanism 4, and the top plate 1 is provided with a placed groove plate 2, and a curved cutting mechanism 3 is provided on the top left side of the bottom plate 1, top of the bottom plate 1. The right side is connected to the placement collection mechanism 4.

[0046]The staff can place the wood on the placement collecting mechanism 4, and the arc-shaped cutting mechanism 3 operates to cut the wood. After cutting, the new wood is pushed into the left, slipping to the left, and the collection mechanism 4 is automatically filtered. Collection, all cut, stop the curved cutting mechanism 3 to operate, collect the finished products and waste of the cut.

Embodiment 2

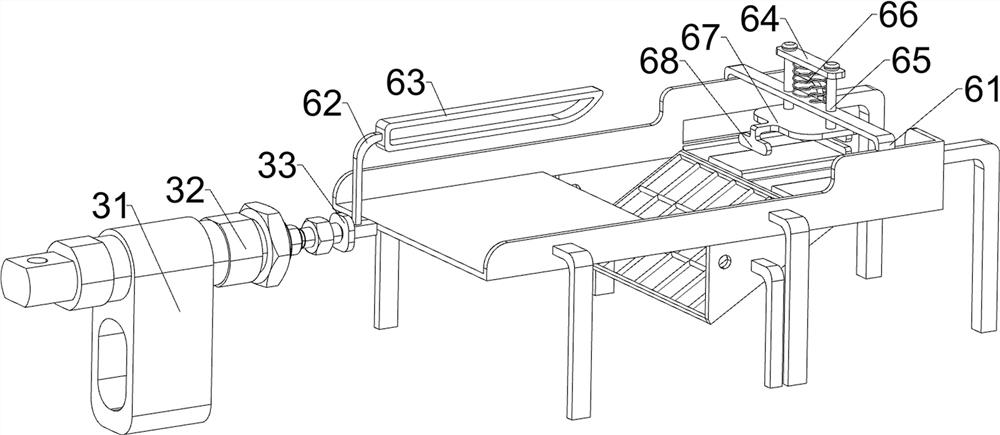

[0048]On the basis of Example 1, such asfigure 2 As shown, the curved cutting mechanism 3 includes a mount 31, a cylinder 32, a telescopic push rod 33, a connecting rod 34, and an arc cutting tool 35. The upper left side of the bottom plate 1 is provided with a mount 31, and the mount 31 is provided with a cylinder. 32. The telescopic push rod 33 is connected to the telescopic rod of the cylinder 32, and the connecting rod 34 is connected to the right side of the telescopic push rod 33, and the arc surface cutting tool 35 is connected to the front and rear sides of the connecting rod 34.

[0049]The placement collecting mechanism 4 includes a support frame 41, a cutting guide plate 42, a pad 43, a screening sheet 44, a finished collecting frame 45, and a waste collecting frame 46, and 6 support frames 41 on top of the bottom plate 1, support frame 41 A cutting guide plate 42 is connected between the top, and the cutting guide plate 42 is opened, and the cutting guide plate 42 is sided,...

Embodiment 3

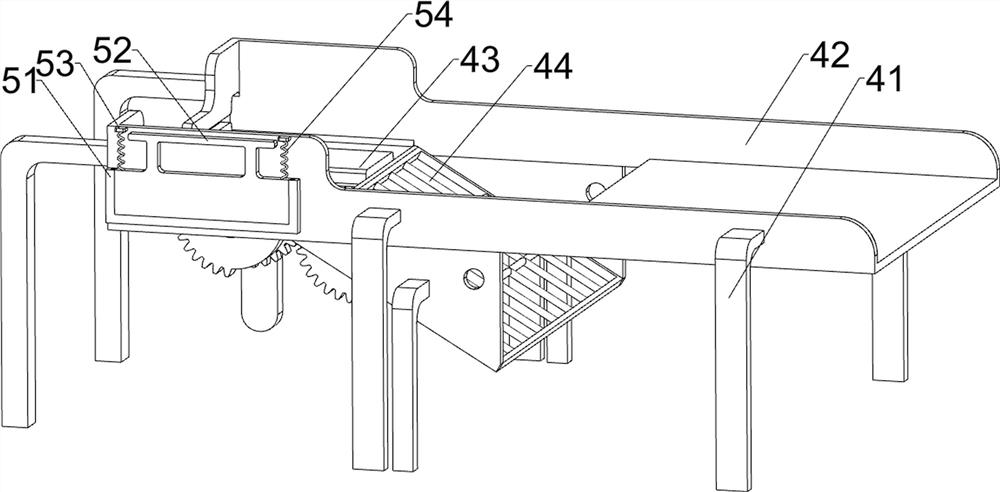

[0052]On the basis of Example 2, such asFigure 3 to 6As shown, there is also included a waste-free drop mechanism 5, and the waste material drop mechanism 5 includes a movable guide plate 51, a hand-pulled bar 52, a mounting plate 53, and a first resident spring 54, and a cutting guide plate 42 rear side. It is provided with a movable guide plate 51, and the movable guide plate 51 is slidably connected to the hand-held plate 52, and the rear side of the cutting guide plate 42 is provided with the mounting plate 53, and the bottom portion of the mounting plate 53 is connected between the hand-drawing plate 52. Limit spring 54.

[0053]In order to prevent the waste from being removed from the upper mouth, the staff can push the hand-held plate 52 upward movement without blocked the upper portion, at which time the first resident spring 54 is compressed. Subsequently, the wood is then pushed, then stops the hand-drawing plate 52, the first restricted spring 54 stretches the hand-pulling p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com