Turning type rolling pin manufacturing device

A technology for manufacturing a device and a rolling pin, which is applied in the field of turning-type rolling pin manufacturing devices, which can solve problems such as low work efficiency, difficulty in controlling the strength and duration of scraping, and unsatisfactory rolling pin effect, so as to achieve good turning effect, reduce workload, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

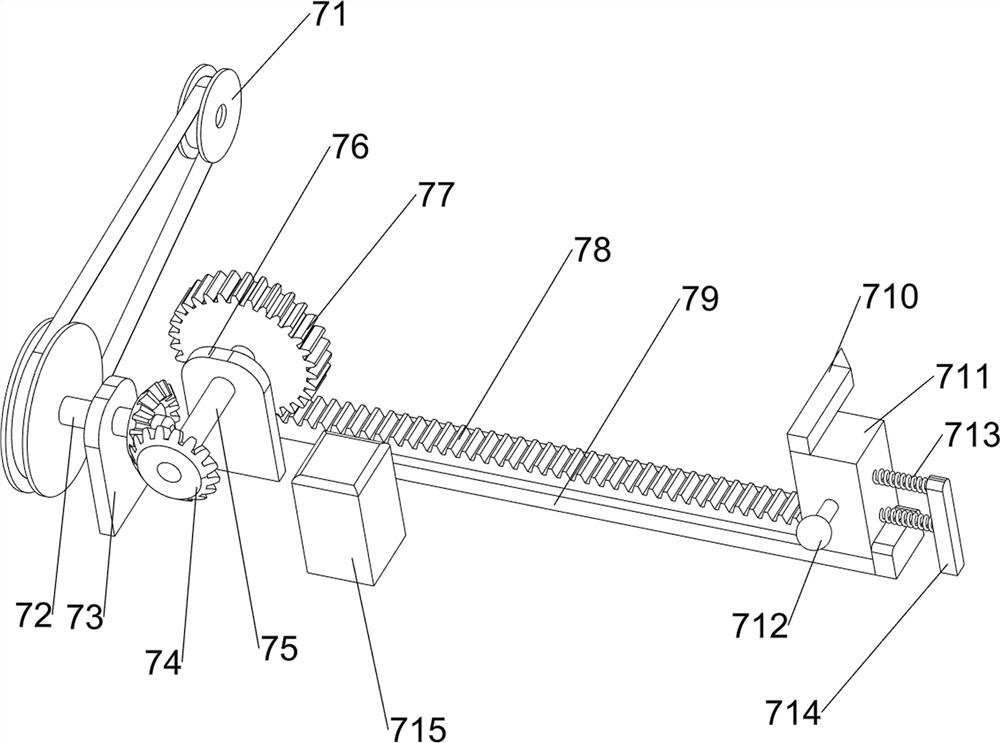

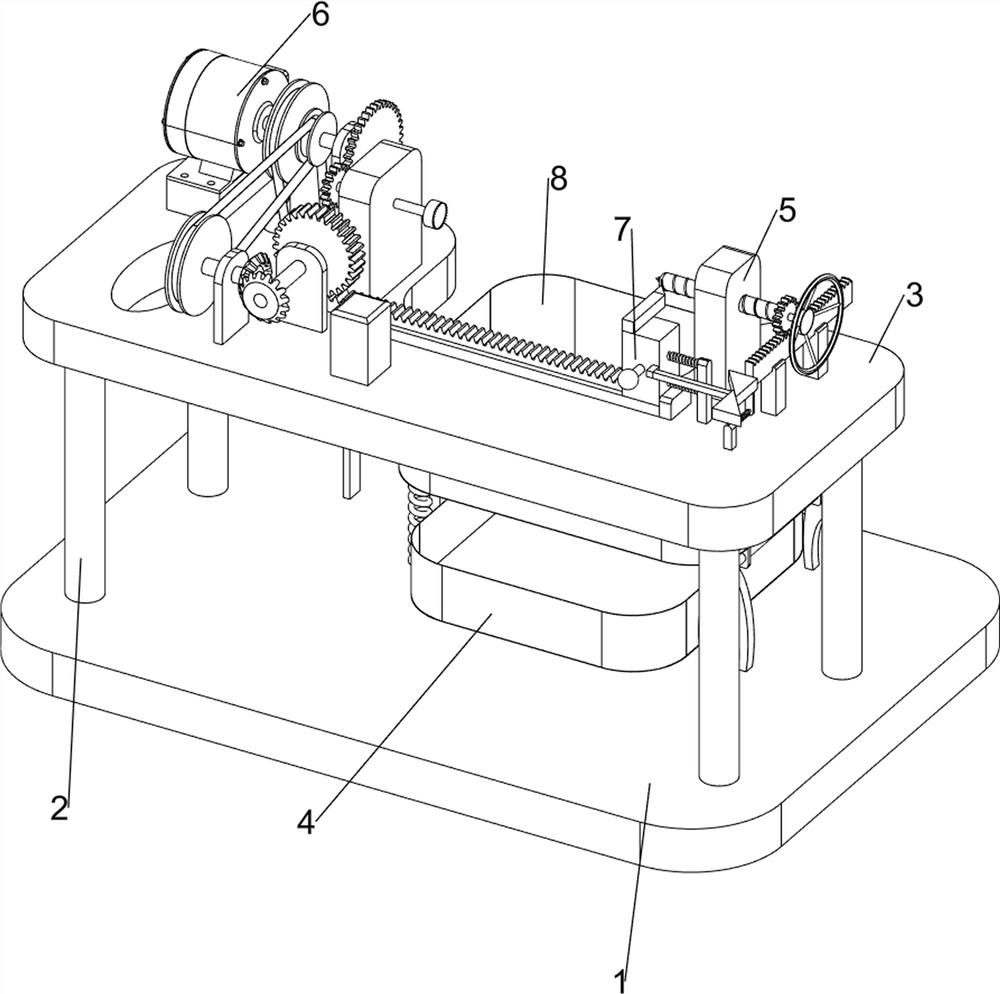

[0076] A turning type rolling pin making device, such as figure 1 As shown, it includes a base 1, a support column 2, a workbench 3, a collection frame 4, a clamping mechanism 5, a rotating mechanism 6 and a turning mechanism 7, and the left and right sides of the base 1 are symmetrically provided with a support column 2, and the support column 2 There is a working table 3 on the upper part, a collecting frame 4 is placed on the rear side of the top of the base 1, a rotating mechanism 6 is arranged on the working table 3, a clamping mechanism 5 is arranged on the working table 3 and the rotating mechanism 6, and the working table 3 and the rotating mechanism 6 is provided with turning mechanism 7.

[0077] When it is necessary to make a rolling pin, people first clamp a log with a certain length and uneven surface into the clamping mechanism 5, then turn the clamping mechanism 5 to clamp the log, and then start the rotating mechanism 6 to make the log rotate At the same time,...

Embodiment 2

[0079] On the basis of Example 1, such as figure 2 , image 3 with Figure 4 As shown, the clamping mechanism 5 includes a first pillar 51, a handle 52, a one-way gear 53, a threaded rod 54, a thimble 55 and a pressing block 56, and the right side of the top of the workbench 3 is provided with a first pillar 51, and the first pillar 51 Top rotary type is provided with threaded rod 54, and threaded rod 54 right part is provided with handle 52 and one-way gear 53, and one-way gear 53 is connected with handle 52 rotationally, and threaded rod 54 left part is provided with thimble 55, and rotary mechanism 6 is provided with There is a pressing block 56 .

[0080] When clamping the log, first prepare a log whose length is about the same as the distance between the thimble 55 and the briquetting block 56, clamp the log between the thimble 55 and the briquetting block 56, and then turn the handle 52 clockwise to drive the screw thread Rod 54 rotates, and threaded rod 54 moves to ...

Embodiment 3

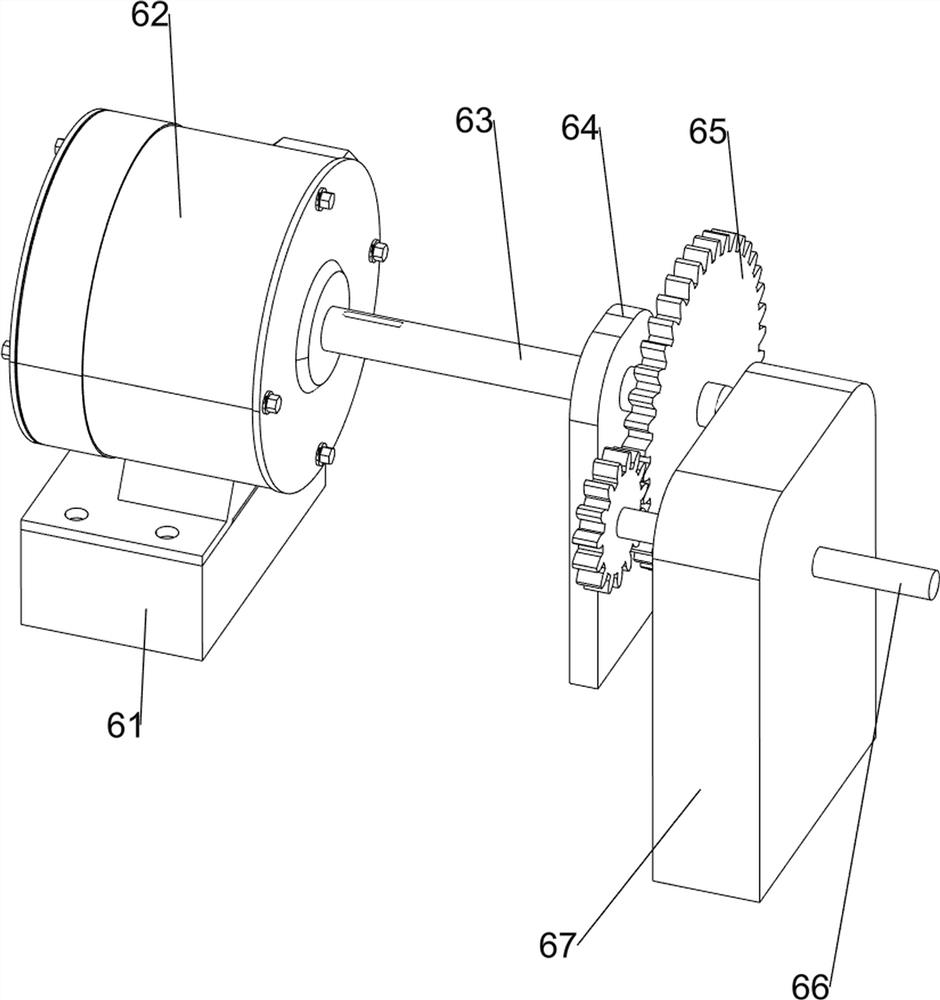

[0086] On the basis of Example 2, such as Figure 5 with Image 6 As shown, it also includes a filter mechanism 8 and a feeding mechanism 9 , the base 1 and the first rotating shaft 63 are provided with a filtering mechanism 8 , and the workbench 3 and the knife rest 711 are provided with a feeding mechanism 9 .

[0087] After turning, the tool rest 711 moves to the right to drive the blanking mechanism 9 to work, and then the log is released from between the thimble 55 and the pressing block 56, so that the log and debris fall into the filter mechanism 8 together, and at the same time the first The rotating shaft 63 rotates and drives the filter mechanism 8 to work, and then debris is screened into the collection frame 4 below, and the logs are left in the filter mechanism 8, and the logs are taken out afterwards, so that automatic feeding can be realized.

[0088] The filter mechanism 8 includes a seventh pillar 81, a fifth rotating shaft 82, a first connecting block 83, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com