Process method for realizing color display on black and white screen

A technology of color display and process method, which is applied in the field of display screen and can solve the problems of multi-color, halftone dots, inability to do anything, low yield, shadow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

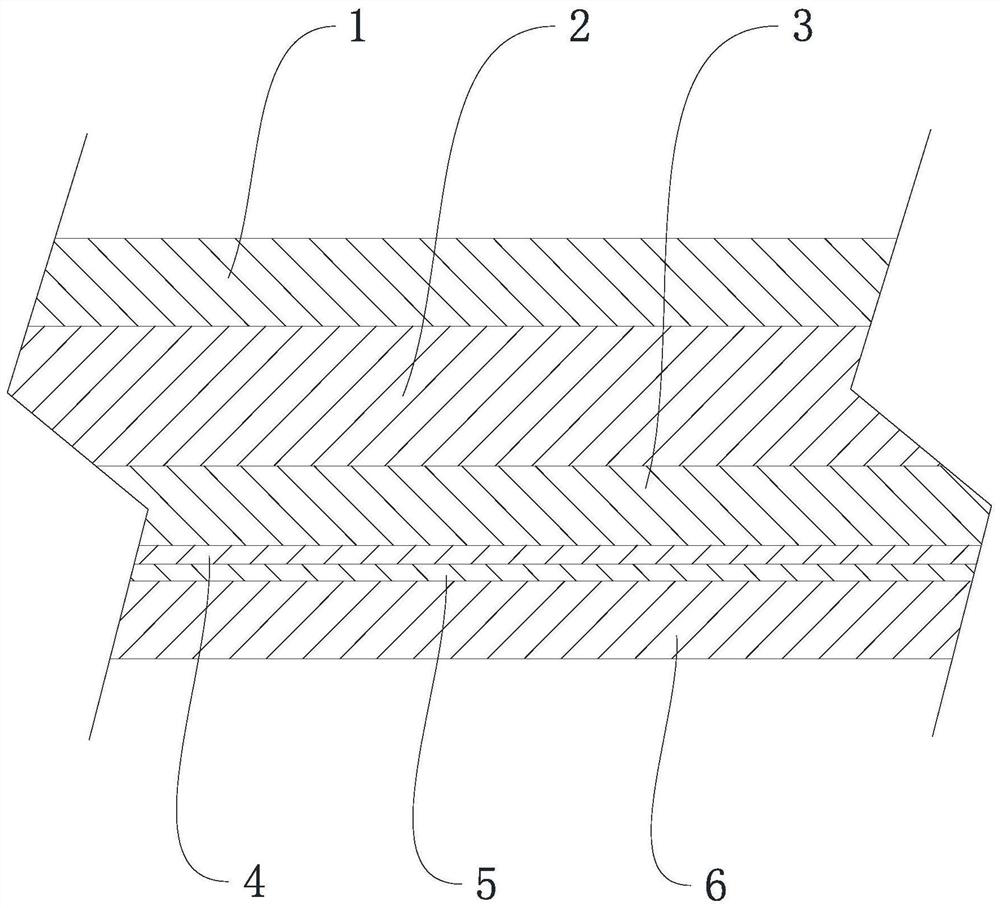

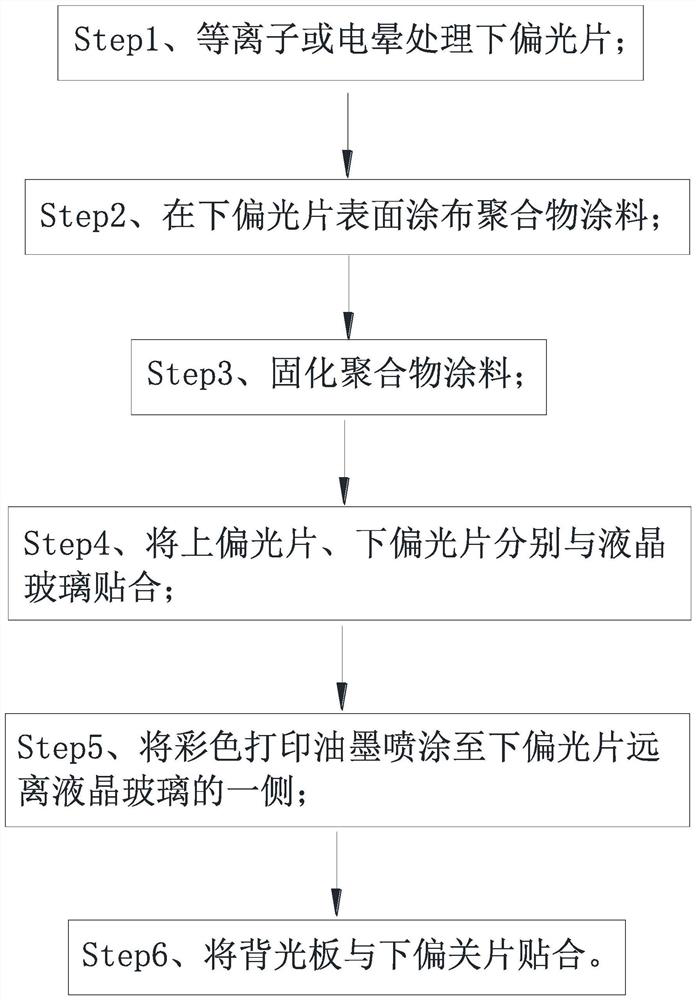

[0037] figure 1 A specific embodiment of the black-and-white-to-color display screen of the present application is shown, and the black-and-white to color display screen includes from top to bottom: an upper polarizer, a liquid crystal glass, a lower polarizer, a polymer coating layer, a color ink layer and a backlight plate. The black and white to color display screen is made through the following process:

[0038] Attach the bottom surface of the upper polarizer and the top surface of the lower polarizer to the two sides of the liquid crystal glass respectively;

[0039] Spray the color printing ink to the side of the lower polarizer away from the liquid crystal glass to form a color ink layer;

[0040] Lay the backlight plate and the lower bias film, and the colored ink layer is located between the two.

[0041] In the above steps, since the color ink layer is directly sprayed on the lower polarizer, there is no need for registering like the silk screen color film in the...

Embodiment 2

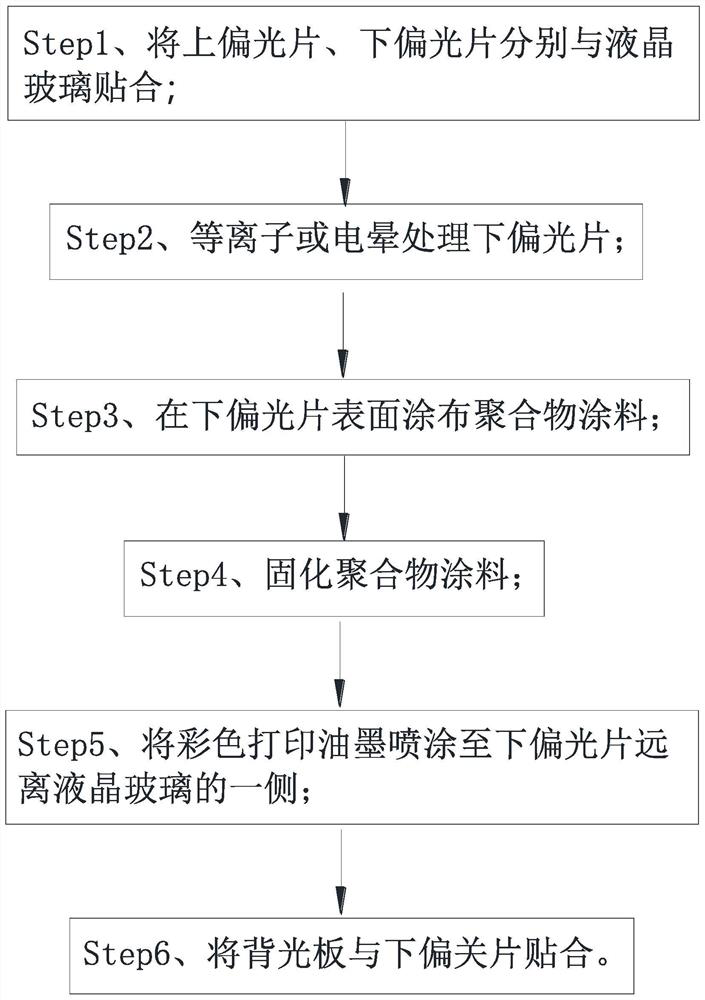

[0065] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the black-and-white-to-color display screen includes from top to bottom: an upper polarizer, a liquid crystal glass, a polymer coating layer, a color ink layer, a lower polarizer, and Backlight. The black and white to color display screen is made through the following process:

[0066] Spraying colored printing ink onto one side of the liquid crystal glass to form a colored ink layer;

[0067] Attach the bottom surface of the upper polarizer and the top surface of the lower polarizer to the two sides of the liquid crystal glass respectively, and the colored ink layer is located between the liquid crystal glass and the lower polarizer;

[0068] Attach the backlight panel to the lower bias film.

[0069] Similarly, the adhesion of the color ink layer on the liquid crystal glass is not good, and it is easy to fall off, resulting in a low yield rate, which cannot meet the requirem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com