Textile production equipment and process for clothing

A technology for production equipment and clothing, applied in transportation and packaging, winding strips, thin material processing, etc., can solve problems such as increased maintenance costs, mechanical failures, and reduced production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

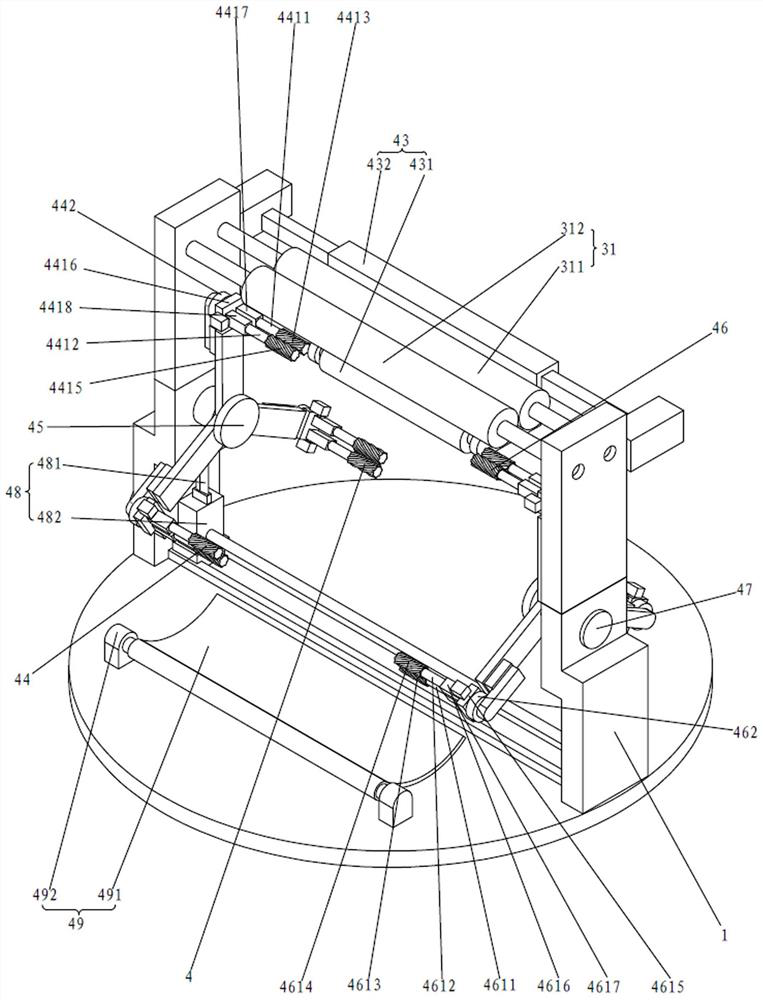

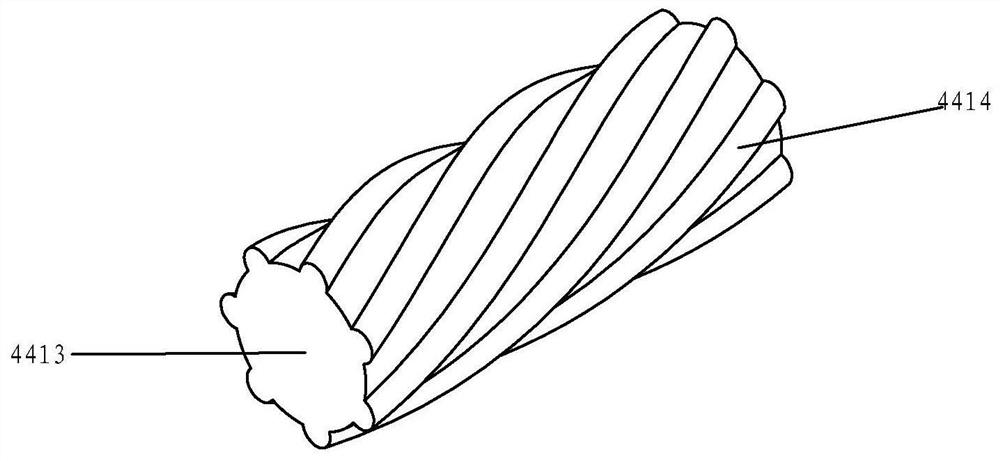

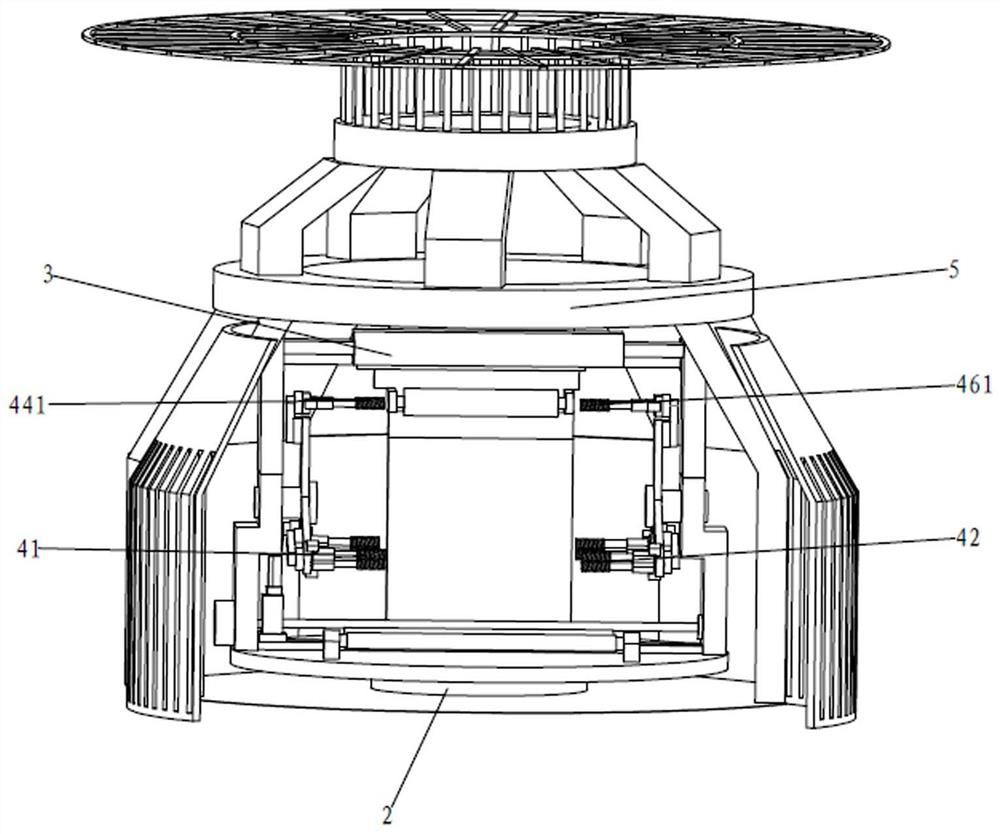

[0046] Such as Figure 1 to Figure 3 As shown, a kind of clothing textile production equipment of the present invention includes a pulling and winding device 1 that winds the woven fabric to form a cloth roll, and a power drive device 2 that drives the pulling and winding device 1 to rotate; the pulling roll The take-up device 1 includes a traction mechanism 3 that pulls the woven cloth, and a cloth collecting mechanism 4 that collects the woven cloth; the cloth collecting mechanism 4 includes a first winding device 41 that winds up one side of the woven cloth, The second winding device 42 that rolls up the other side of the fabric, and the positioning device 43 that positions the woven cloth; the first winding device 41 includes a first winding mechanism 44 that winds the woven cloth, and drives the first A first rotary drive devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com