Automatic secondary feeding method for rare earth alloy smelting

A secondary feeding, rare earth alloy technology, applied in lighting and heating equipment, furnace types, furnaces, etc., can solve the problems of alloy liquid sputtering, potential safety hazards, oxygen leakage, etc., to improve work efficiency, reduce volatilization and composition the effect of fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

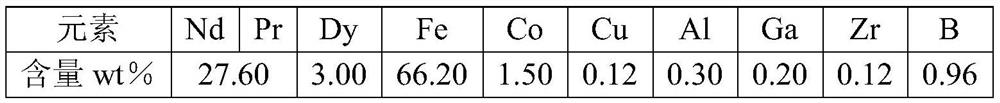

[0023] In the raw material preparation process: prepare Nd with a purity of 99.5% 75 PR 25 , Dy with a purity of 99.8%, Fe-B for industrial use, pure Fe and Co for industrial use, Cu and Al with a purity of 99.5% and Ga with a purity of 99.999%, and ZrFe for industrial use, prepared in ten parts by weight percent wt%. The contents of each element are shown in Table 1:

[0024] Table 1: The content of each element of embodiment and comparative example

[0025]

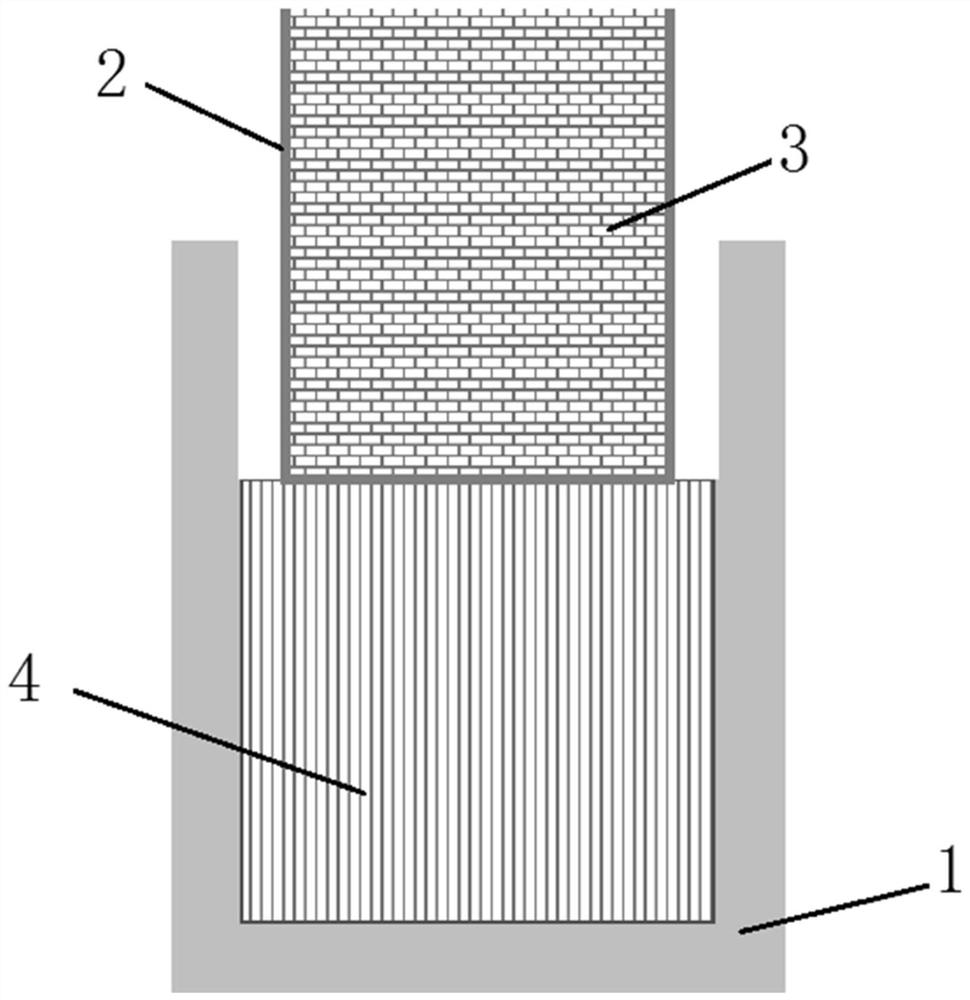

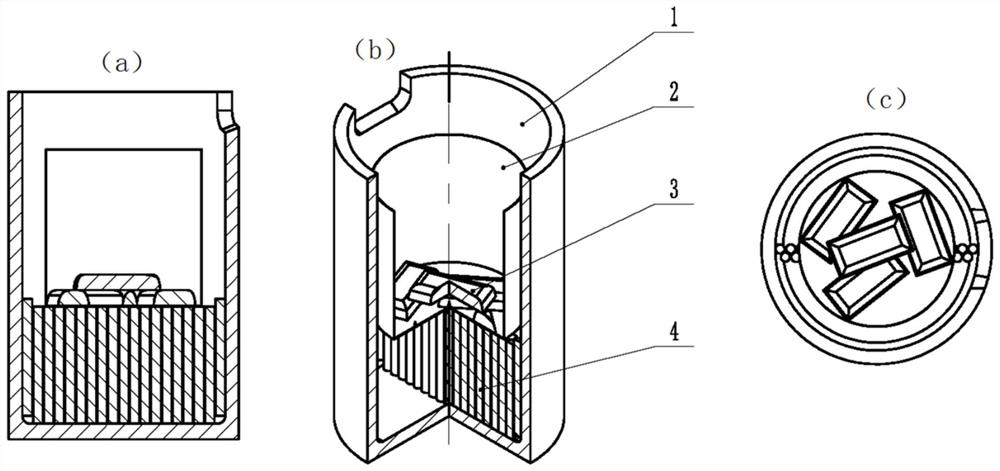

[0026] Among them, five parts were used as comparative examples by conventional methods, directly put into alumina crucibles, smelted in a high-frequency vacuum induction melting furnace, refined at 1500 ° C for 5 minutes, and then adjusted the heating power to cool down to 1430 ° C, using Casting is carried out by a single-roll quenching method to obtain strip strips. At room temperature, put the spin strip into the hydrogen blasting furnace and pass in hydrogen gas with a purity of 99.5%. After absorbing hydroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com