A steel friction hinge energy-dissipating tie-beam structure for double-column piers and its construction method

A technology for tying beams and beams, applied in the field of steel friction hinge energy-dissipating tie-beam structures and their construction, can solve the problems of rigidity, stability impact, labor cost, beam deformation, etc. Compressive stability and lateral stiffness, easy repair, and the effect of reducing residual deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

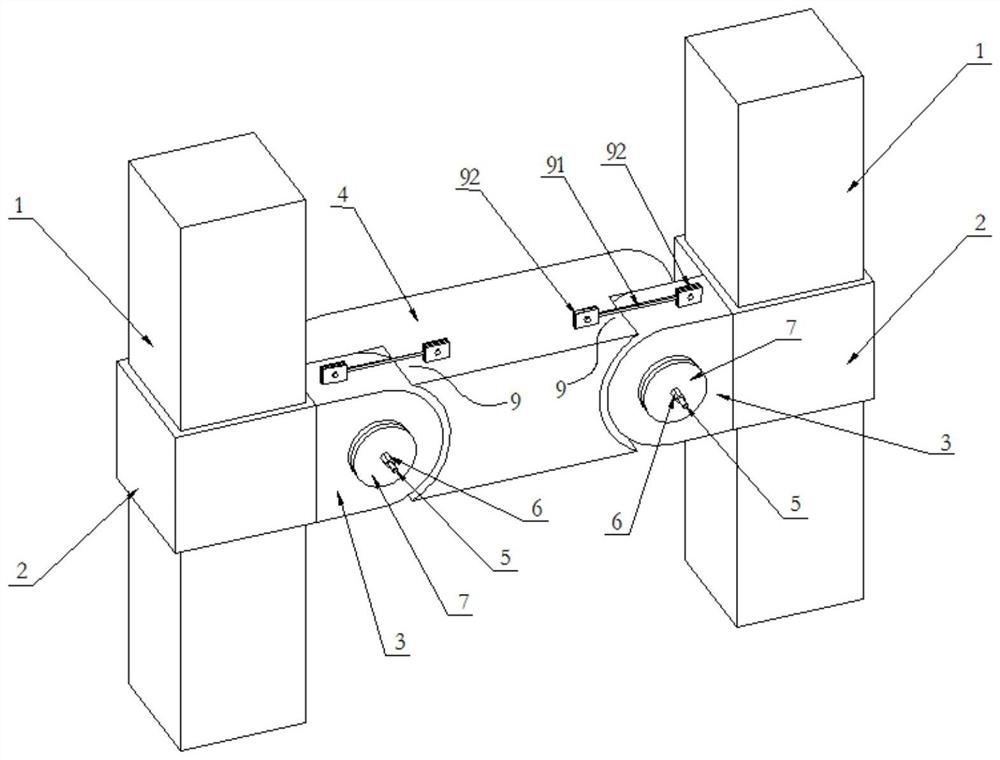

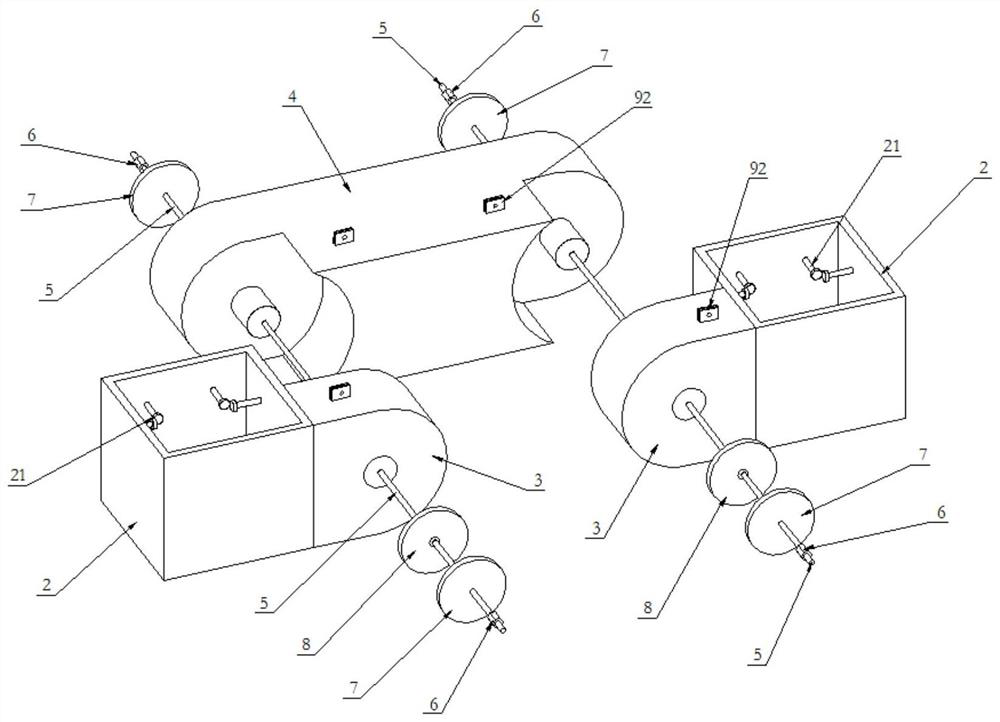

[0023] combined with Figure 1-5 , the specific embodiments of the present invention are described as follows:

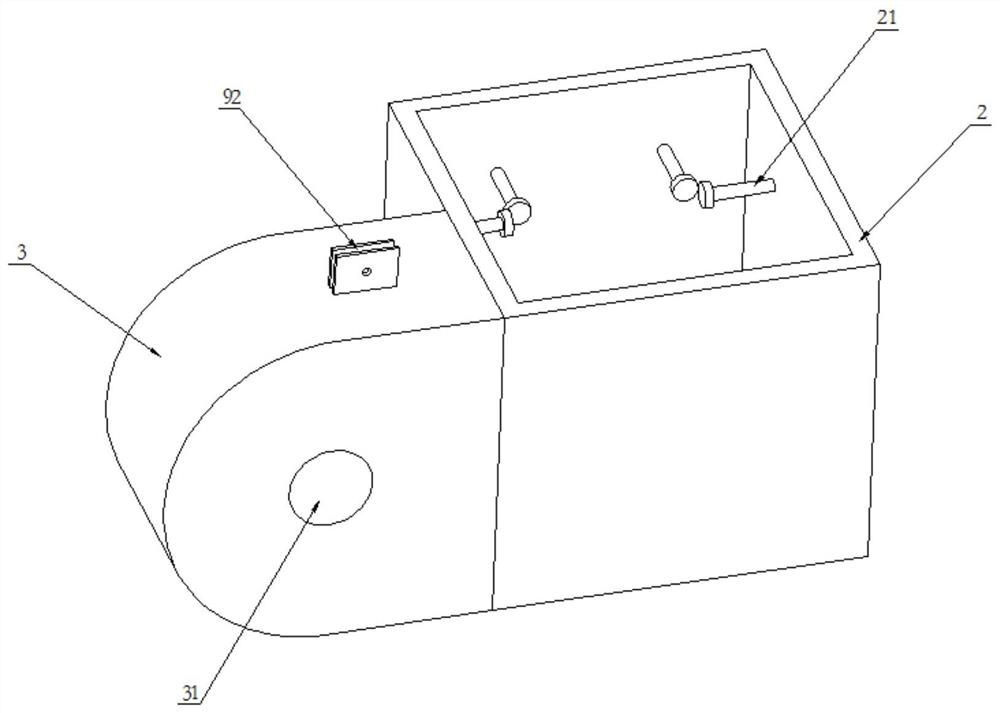

[0024] like figure 1 , 2 , 3, 4, and 5, a steel friction hinge energy-dissipating tie beam structure for a double-column pier, including a pier column 1, a beam 4, and both ends of the beam 4 are connected by steel sleeves 2 and ear beams 3 respectively. On the outer walls of the two vertically arranged pier columns 1, the steel sleeve 2 is sleeved on the outer wall of the pier column 1 through shear welding studs 21, one end of the ear beam 3 is welded to the outside of the steel sleeve 2, and the other end is through the prestressed steel bar. The pressure applied by 5 is connected with the beam 4 to form a steel friction hinge structure.

[0025] Wherein, in the whole steel friction hinge structure, the other end of the ear beam 3 is provided with a semicircle, the center of the semicircular part of the ear beam 3 is provided with an ear beam through hole 31, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com