Gas supercharging device

A gas pressurization and two-stage pressurization technology, which is applied in the direction of liquid displacement machinery, piston pumps, multi-stage pumps, etc., can solve the problems of increasing piston area, reducing motor life, piston seal life, and increasing noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

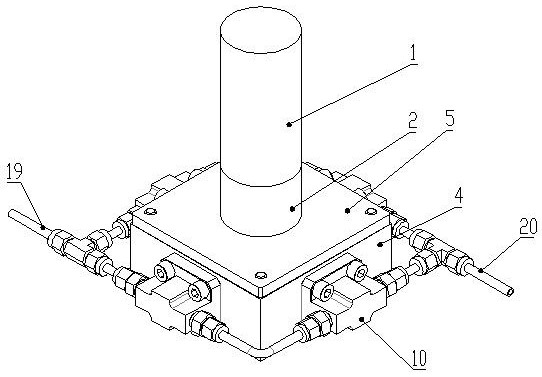

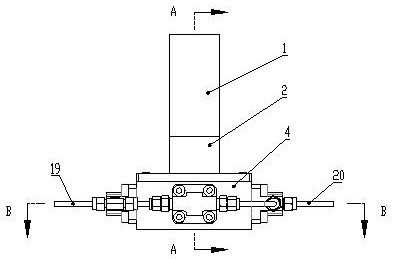

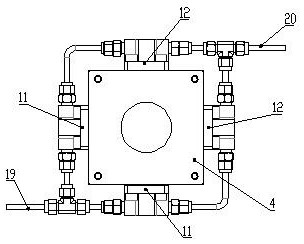

[0026] A gas supercharging device includes an air inlet 19, an output port 20, at least two stages of supercharging components, an eccentric component that provides reciprocating driving force for each level of supercharging component, and a drive mechanism that provides rotational motion for the eccentric component, each stage The booster assemblies are all provided with piston assemblies, and a single set of piston assemblies includes a cylinder 10 and a piston rod matched with the cylinder 10. The difference between different stages of booster assemblies is that the volume of the cavity of the cylinder 10 of the piston assembly is different. The pressure assembly is connected in series between the air inlet 19 and the output port 20 through the connecting air pipe, and the air path along the air inlet 19 to the output port 20 is recorded as a pressurized air path, Figure 5 The direction indicated by the middle arrow is the direction of gas flow. In the direction of the pres...

Embodiment 2

[0029] On the basis of Embodiment 1, a transmission case 4 is also included, the drive mechanism is installed on the transmission case 4, and the eccentric assembly is installed in the transmission case 4. The drive mechanism includes a motor 1 and a reducer 2, and the eccentric assembly It includes an eccentric shaft 6 and an eccentric top block arranged coaxially. The output shaft of the reducer 2 is connected to the eccentric shaft 6 through a flat key 3. The eccentric top block is installed on the outer ring of the eccentric shaft 6. The cylinder 10 is installed on the transmission On the side wall of the box body 4, one end of the piston rod extends into the cavity of the cylinder 10, and the other end of the piston rod abuts against the outer periphery of the eccentric top block, that is, the other end of the piston rod contacts the outer periphery of the eccentric top block. , its outer edge is always in contact with the other end of the piston rod and pushes the piston ...

Embodiment 3

[0032] On the basis of Embodiment 2, the lower part of the eccentric shaft 6 is rotationally connected with the transmission case 4 through the small bearing 8, the small bearing 8 is fixed on the bottom of the transmission case 4, and the eccentric top block adopts the large bearing 7 and is installed on the eccentric On the top of the shaft 6, the inner ring of the large bearing 7 is axially fixed by a circlip 9. The large bearing 7 is used to press the different piston rods sequentially. During the eccentric rotation process of the inner ring of the large bearing 7 with the eccentric shaft 6, the outer ring of the large bearing 7 presses the piston rods of different piston assemblies in turn, so that they face the cavity of the cylinder 10 The interior moves in a straight line. During the pressurization process, the outer ring of the large bearing 7 and the inner ring of the large bearing 7 will have a certain relative rotation, which can effectively avoid the vibration caus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com