Straight pipeline inner wall surface temperature measurement and transient identification method and computer terminal

A technology of temperature measurement and recognition method, which is applied to thermometers, thermometer parts, computer-aided design, etc. It can solve problems such as easy vibration and divergence, difficulty in meeting real-time output requirements, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

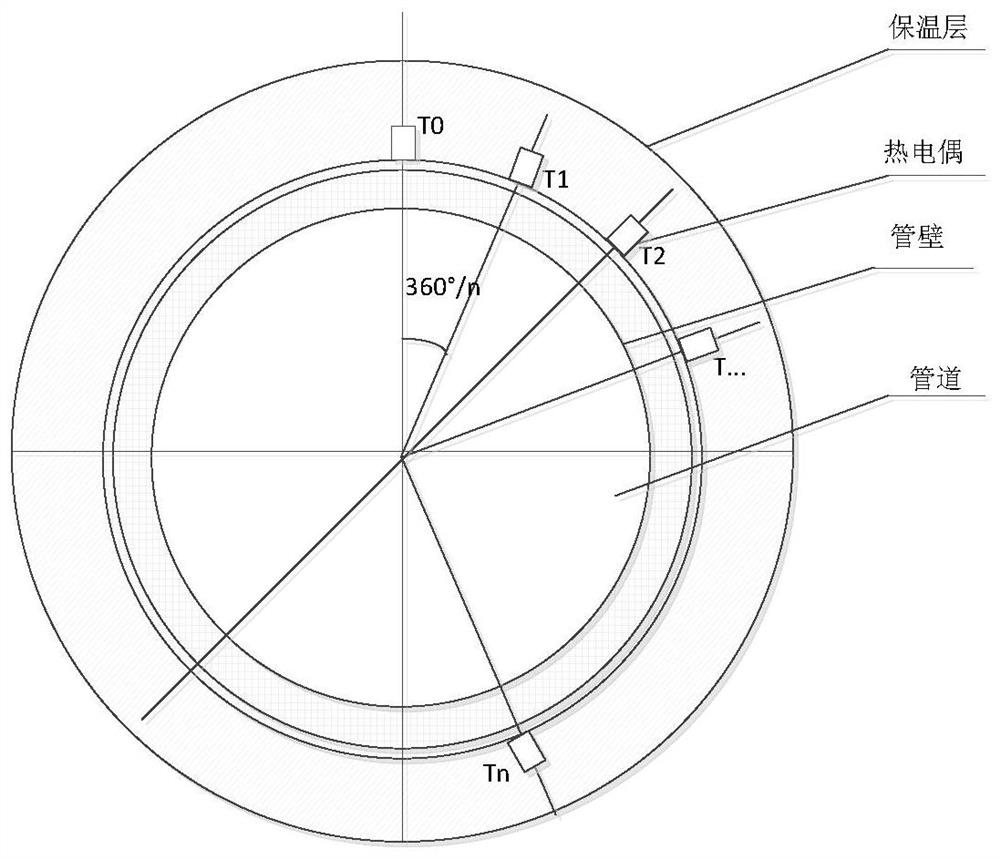

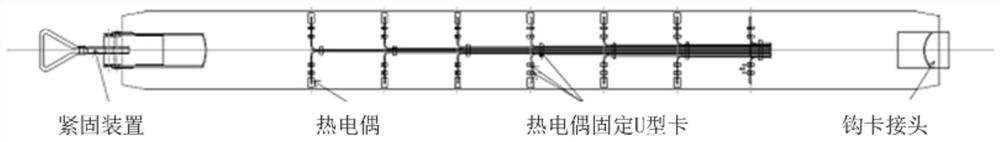

[0090] The present invention can calculate the temperature field information of the inner surface of the pipeline through the real-time measurement information of the temperature of the outer wall surface of the pipeline, and adopts the reverse space step by step to calculate the temperature field information of the inner surface of the pipeline, avoiding repeated iterations, saving calculation time and amount of calculation, and can also quickly identify the temperature of the inner wall surface of the pipeline Actual temperature transient information.

[0091] refer to figure 1 , figure 1 It is a schematic flowchart of Embodiment 1 of the method for measuring the temperature of the inner wall surface of a straight pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com