Diaphragm of anti-sticking film/anti-flapping film of chromatic harmonica

An anti-film, chromatic technology, applied to wind instruments, instruments, musical instruments, etc., can solve the problems of improper piano oil, film film, noise and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described below with reference to the accompanying drawings.

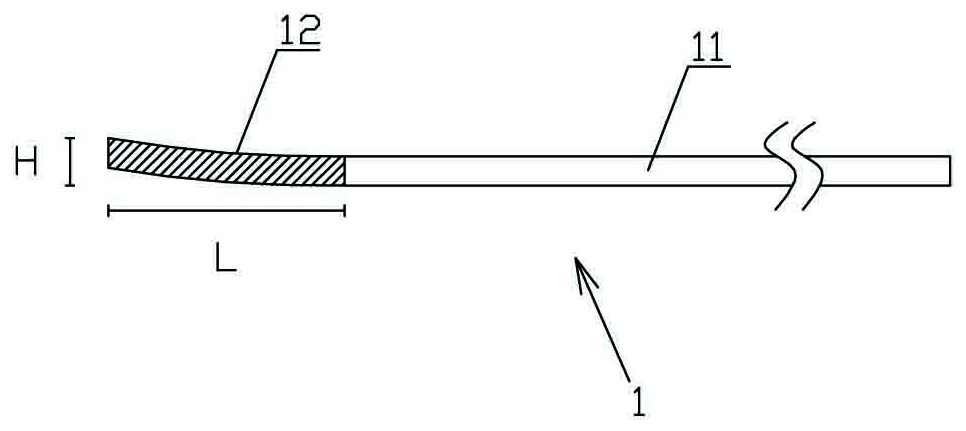

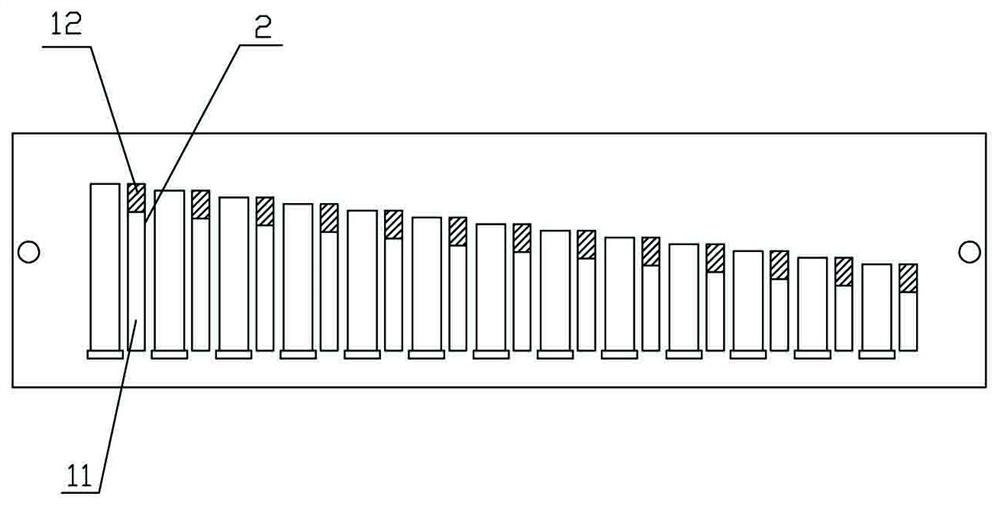

[0020] Such as figure 1 and figure 2 As shown, a diaphragm of an anti-adhesive film / anti-beat film of a chromatic harmonica includes a diaphragm body 1, and the diaphragm body is composed of a flat section 11 and an arc section 12. The flat section 11 Parallel to the horizontal plane, the front end of the arc section 12 is connected to the end of the tiled section 11, and the arc section 12 is gradually bent upwards from front to back; The height H is 1.3-1.8mm, and the length L of the arc section 12 is 10-12mm. The length L of the arc segment 12 is the distance between the front end and the end of the arc segment 12 .

[0021] Furthermore, the flat section 11 and the arc section 12 are integrally formed.

[0022] Furthermore, the height H of the arc segment 12 is 1.3 mm, and the length L of the arc segment 12 is 10 mm.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com