A new production process and material distribution device for soft stone secondary distribution

A secondary fabric and production process technology, applied in the direction of supply devices, manufacturing tools, ceramic molding machines, etc., can solve the problems of reinforcement exposure, falling off, and difficulty in controlling the thickness of soft stones, and achieve uniform thickness, simple structure, and solve the problem of exposure and the effect of shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 This embodiment 1 provides a new production process for soft stone secondary cloth, including the following steps:

[0027] (1) Prepare soft stone mixture and set the thickness of soft stone cloth;

[0028] (2) Lay the first layer of soft stone mixture in the mold. The thickness of the first layer of soft stone mixture is one-third of the thickness of the preset soft stone cloth, and the first layer of soft stone mixture is subjected to high heat Dries in a short time to complete the first cloth;

[0029] (3) Add required reinforcements on the first layer of soft stone mixture after drying above, so that the reinforcement is laid flat on the first layer of soft stone mixture after drying, and the reinforcement is a grid cloth;

[0030] (4) Lay the second layer of soft stone mixture on the first layer of soft stone mixture after adding reinforcements, and the thickness of the second layer of soft stone mixture is according to the thickness and design of th...

Embodiment 2

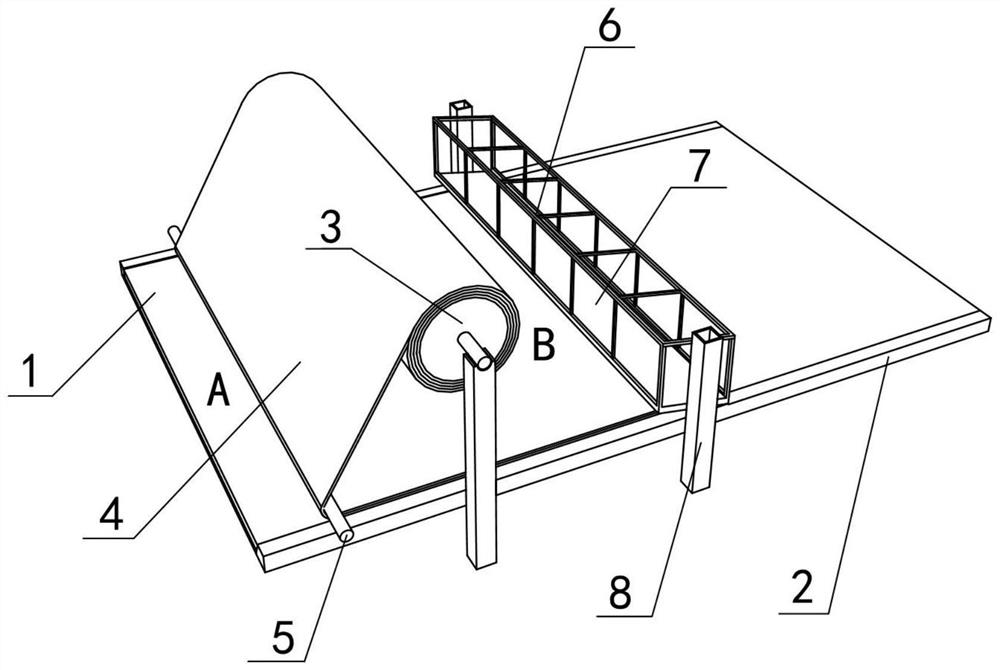

[0032] Example 2 as figure 1 As shown, the present embodiment 2 provides a soft stone secondary distribution device, including a conveyor belt (not shown in the figure), a mold 1 arranged on the conveyor belt, and a mold bottom arranged on both sides of the mold 1 Frame 2, above the mold 1 along the conveying direction of the conveyor belt, there are rollers 3 and jigs 6 with reinforcements 4 in sequence. The layers of soft stone mixture are pressed together, and the jig 6 smooths and sets the thickness of the second layer of soft stone mixture laid on the reinforcement member 4 in area B.

[0033] In the soft stone secondary distribution device of this embodiment, the reinforcing member 4 is a grid cloth.

[0034] In the soft stone secondary distribution device of this embodiment, the pressing rod 5 is fixed on the mold chassis 2 .

[0035] On the soft stone secondary distributing device of this embodiment, the slab 7 at the bottom of the fixture 6 is obliquely arranged abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com