Epoxy molding compound for infrared receiving head and preparation method thereof

A technology of epoxy molding compound and receiving head, which is applied in the field of epoxy molding compound, which can solve the problems of infrared light transmission, cost increase, and oil spots on the appearance of products, so as to reduce the number of times of use, improve mold release, and reduce oil spot effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

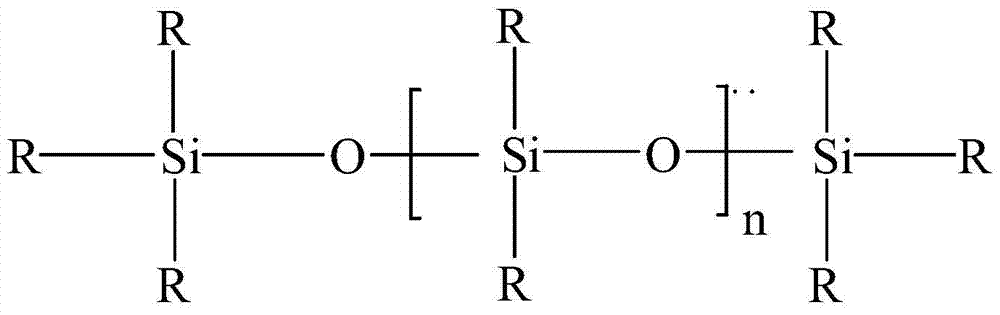

Method used

Image

Examples

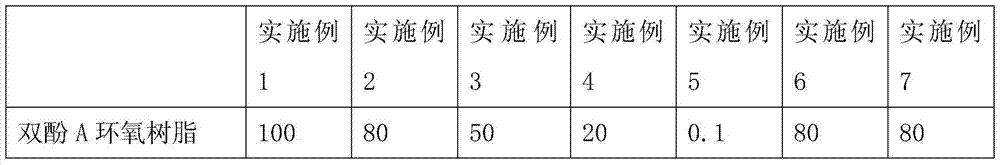

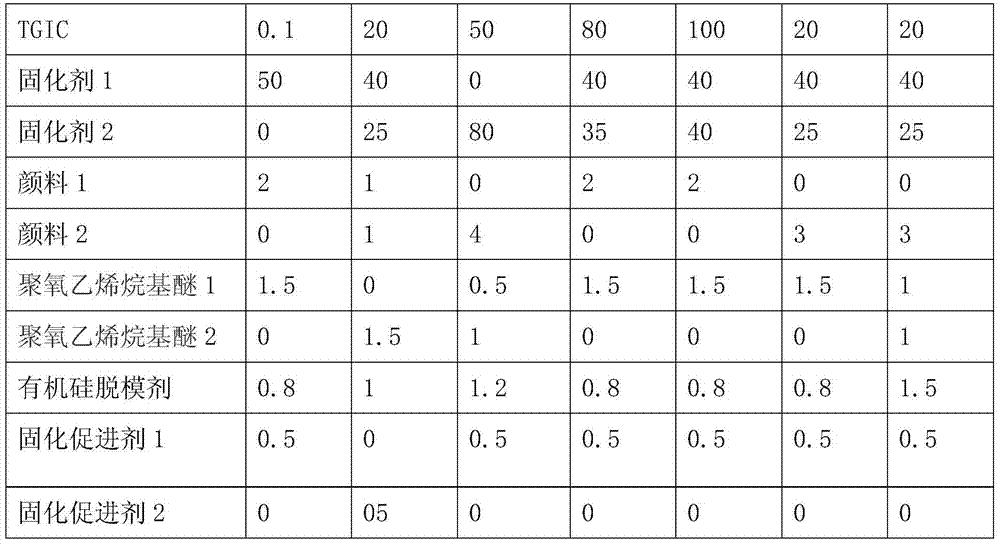

Embodiment 1

[0029] Epoxy plastic encapsulant for infrared receiver and its preparation: weigh the components according to the proportions in Table 1, and fully melt and mix bisphenol A epoxy resin, TGIC and infrared colorant at 80°C for 40 minutes, and then add silicone to remove Molding agent, polyoxyethylene alkyl ether, curing agent, keep at 80℃ and fully melt and mix for 40min. Cool down to 60°C, add curing accelerator, and mix for 5 minutes. The melt-mixed mixture is cooled to room temperature, crushed and pre-compressed, and the performance is tested.

Embodiment 2

[0031] Epoxy molding compound for infrared receiver and its preparation: weigh the components according to the proportions in Table 1, and fully melt and mix bisphenol A epoxy resin, TGIC and infrared colorant at 100°C for 20 minutes, and then add silicone to remove Molding agent, polyoxyethylene alkyl ether, curing agent, keep 100℃ and fully melt and mix for 20min. Cool down to 70°C, add curing accelerator, and mix for 5 minutes. The melt-mixed mixture is cooled to room temperature, crushed and pre-compressed, and the performance is tested.

Embodiment 3

[0033] Epoxy plastic encapsulant for infrared receiver and its preparation: weigh the components according to the proportions in Table 1, and fully melt and mix bisphenol A epoxy resin, TGIC and infrared colorant at 120°C for 5 minutes, and then add silicone to remove Molding agent, polyoxyethylene alkyl ether, curing agent, keep 120°C and fully melt and mix for 5 minutes. Cool down to 80°C, add curing accelerator, and mix for 3 minutes. The melted and mixed mixture is cooled to room temperature, crushed and pre-compressed, and the performance is tested.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com