Patents

Literature

33results about How to "Prevent filming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Toner for developing electrostatic image, method for producing the same, developer, image forming apparatus, process cartridge, and image forming method

InactiveCN1755531APrevent filmingEasy to cleanElectrographic process apparatusDevelopersLatent imageImage formation

In an image-forming device (20), the toner developing the electrostatic latent image consists of at least a binding resin and a colorant and the surface of the toner is arranged with an external additive. The invention is characterized in that when the toner is added to the electrolytic solution with a surface-active agent added in for dispersion, the amount of the free external additive dissociating from the surface of the toner is between 7 to 50 percent.

Owner:RICOH KK

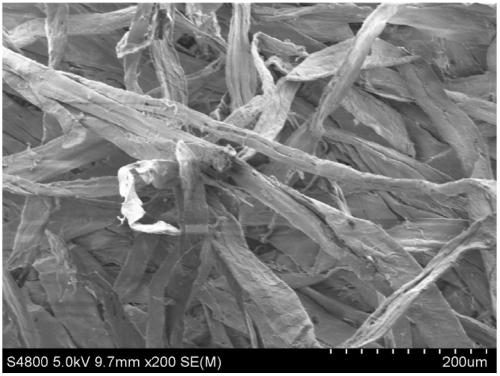

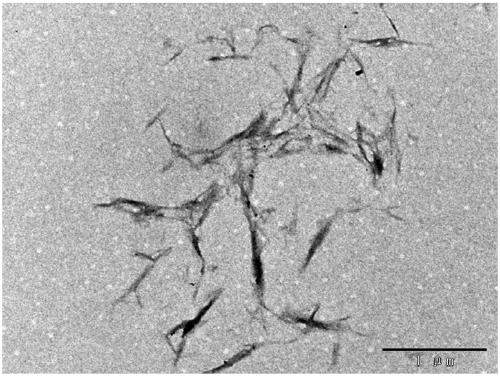

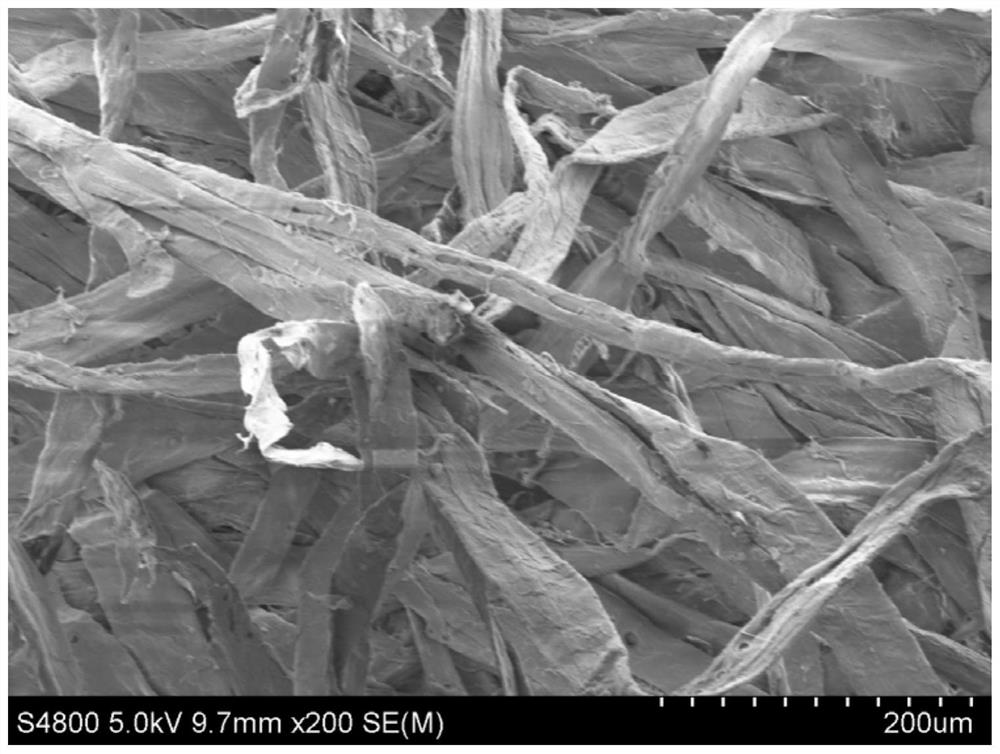

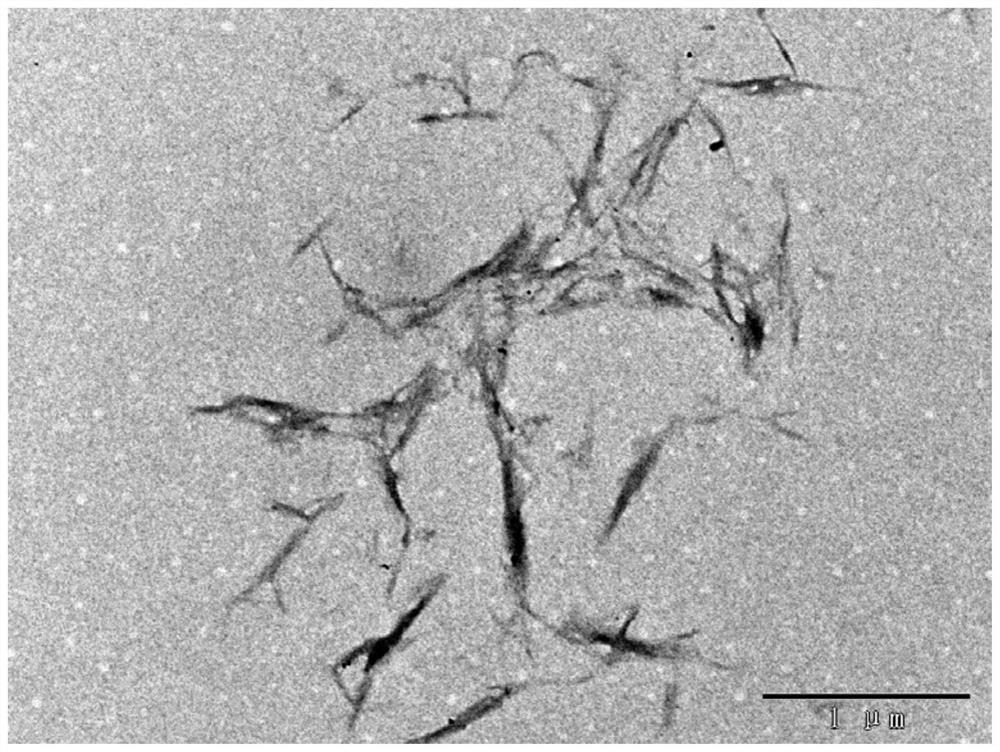

Preparation method of nano-cellulose fiber dry powder

The invention relates to a preparation method of nano-cellulose fiber dry powders which comprises the following steps: 1) taking, pulverizing and drying cellulose to obtain a cellulose raw material for later use; 2) mixing organic acid with alcohol to obtain reaction liquid in which the organic acid takes up 20-30% by mass, heating the reaction liquid to 140 to 160 DEG C, adding the cellulose rawmaterial obtained in step (1), preserving heat and mixing; 3) after the cellulose raw material is sufficiently destroyed and dispersed, performing solid-liquid separation treatment in a reaction system to obtain reaction recovery liquid and solid powder, washing the powder with alcohol, and then dispersing the solid powder in the alcohol to obtain solid powder dispersion liquid; 4) homogenizing the solid powder dispersion liquid obtained in step 3) to obtain nano-cellulose fiber dispersion liquid; 5) evaporating the alcohol in the nano-cellulose fiber dispersion liquid obtained in step 4) to dryness, so as to obtain the nano-cellulose fiber dry powder.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

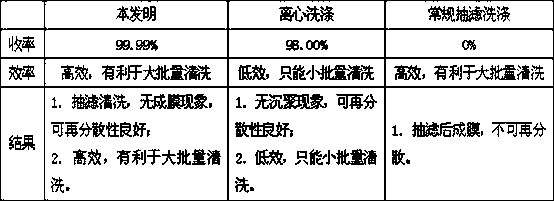

Cleaning method of metal nanowire

ActiveCN106862553AEfficient cleaningTime consuming to overcomeTransportation and packagingMetal-working apparatusSolventChemistry

The invention discloses a cleaning method of a metal nanowire. The cleaning method comprises the coating procedure, cleaning procedure, dispersion procedure and removing procedure. The cleaning method of the metal nanowire is characterized in that a protective layer is formed on the surface of the metal nanowire, coagulation of the metal nanowire is effectively prevented through the protective layer during follow-up suction filtration washing, a solvent, organic polymers and inorganic salt are removed through suction filtration washing, and finally, the protective layer on the surface of the metal nanowire is removed. The cleaning method has the beneficial effects that the quick and efficient cleaning technology of the metal nanowire overcomes the defects that centrifugal washing time is long, operation is complex and efficiency is low, coagulation of the metal nanowire is effectively prevented through the protective layer during follow-up suction filtration washing, the metal nanowire is quickly and efficiently cleaned, the film forming phenomenon during the filtration washing process is effectively avoided, yield of a product is increased, and quality of the product is improved.

Owner:山东利特纳米技术有限公司

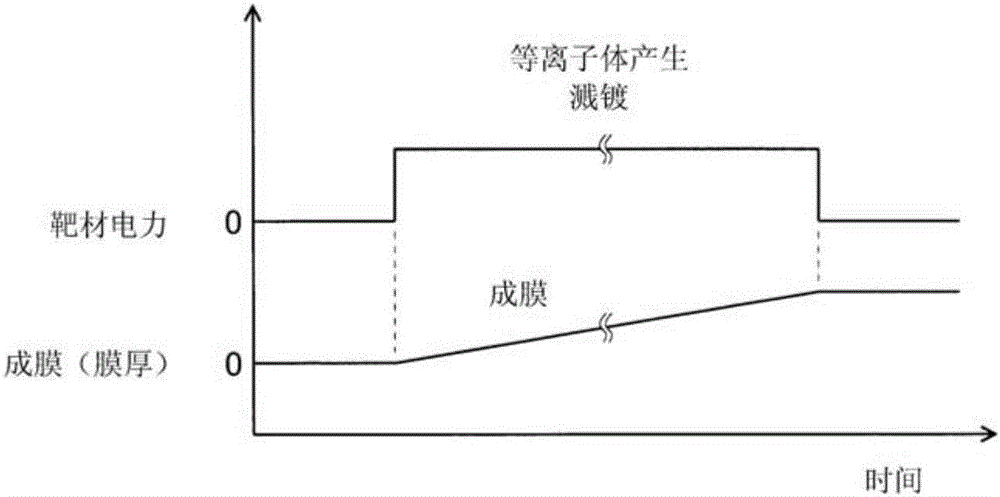

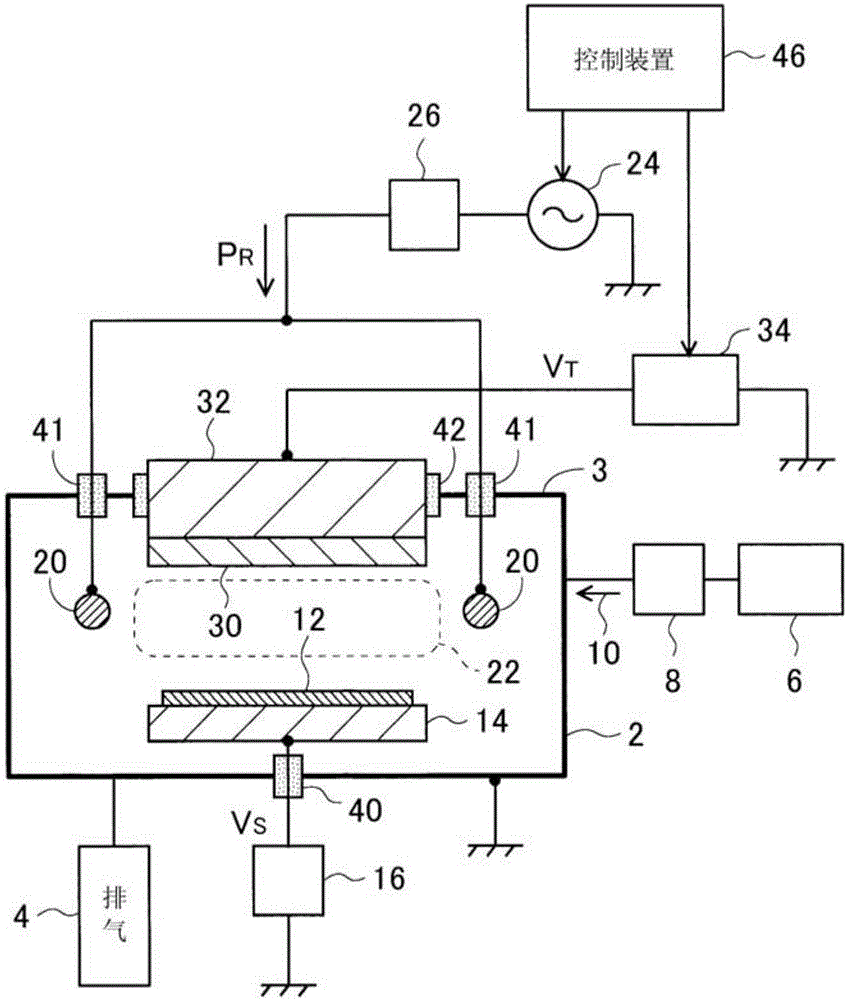

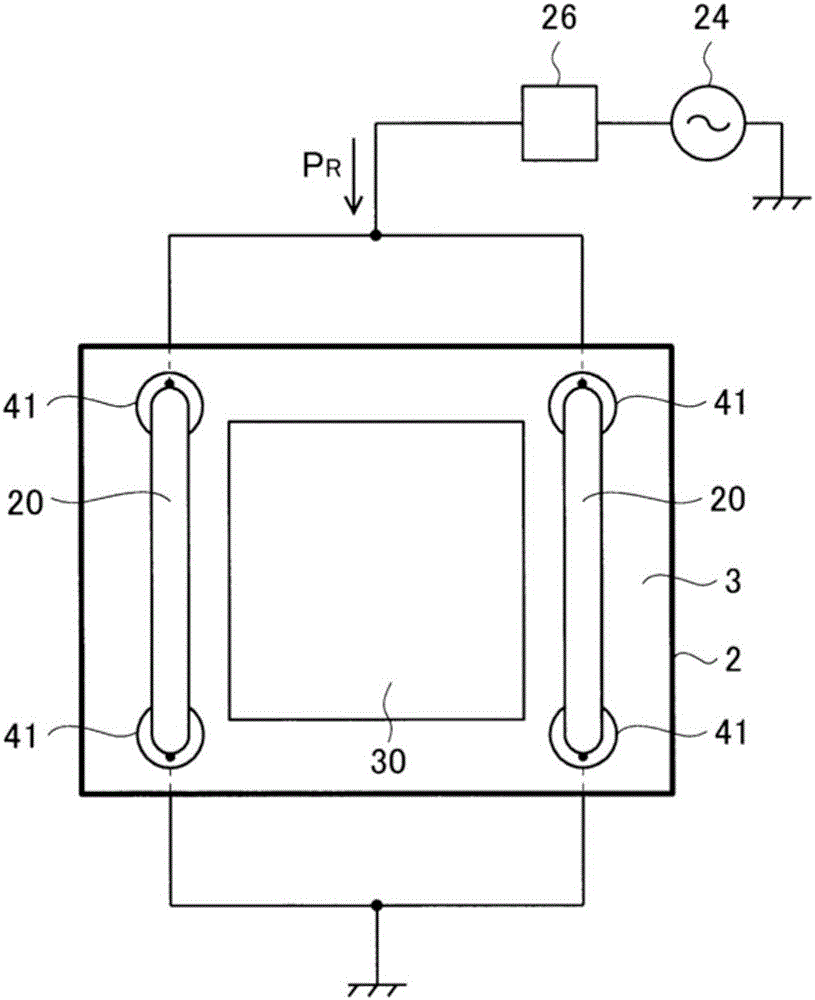

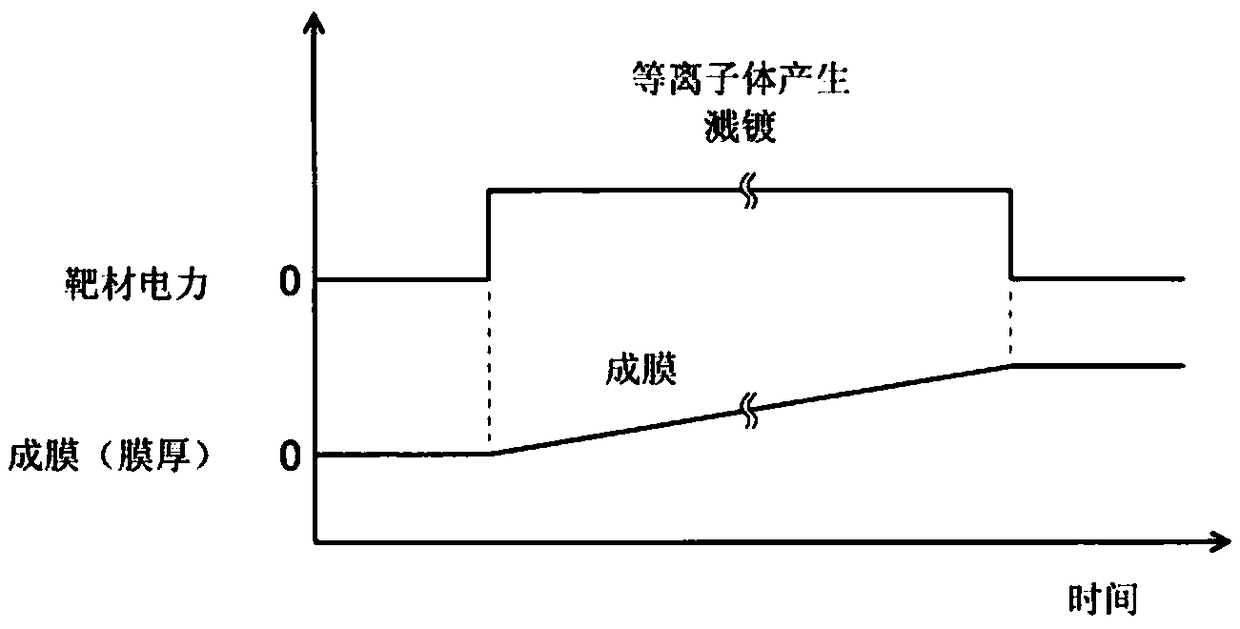

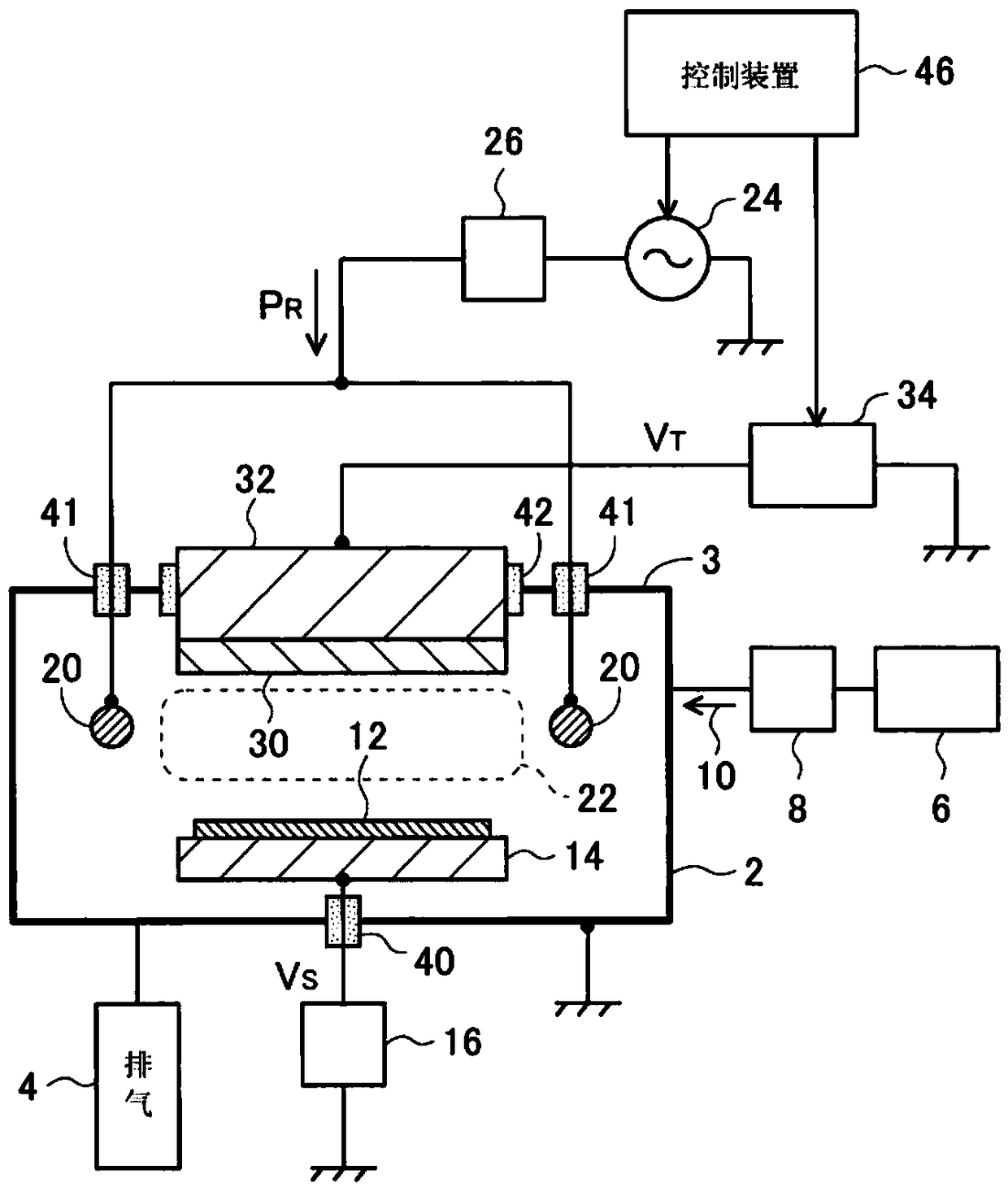

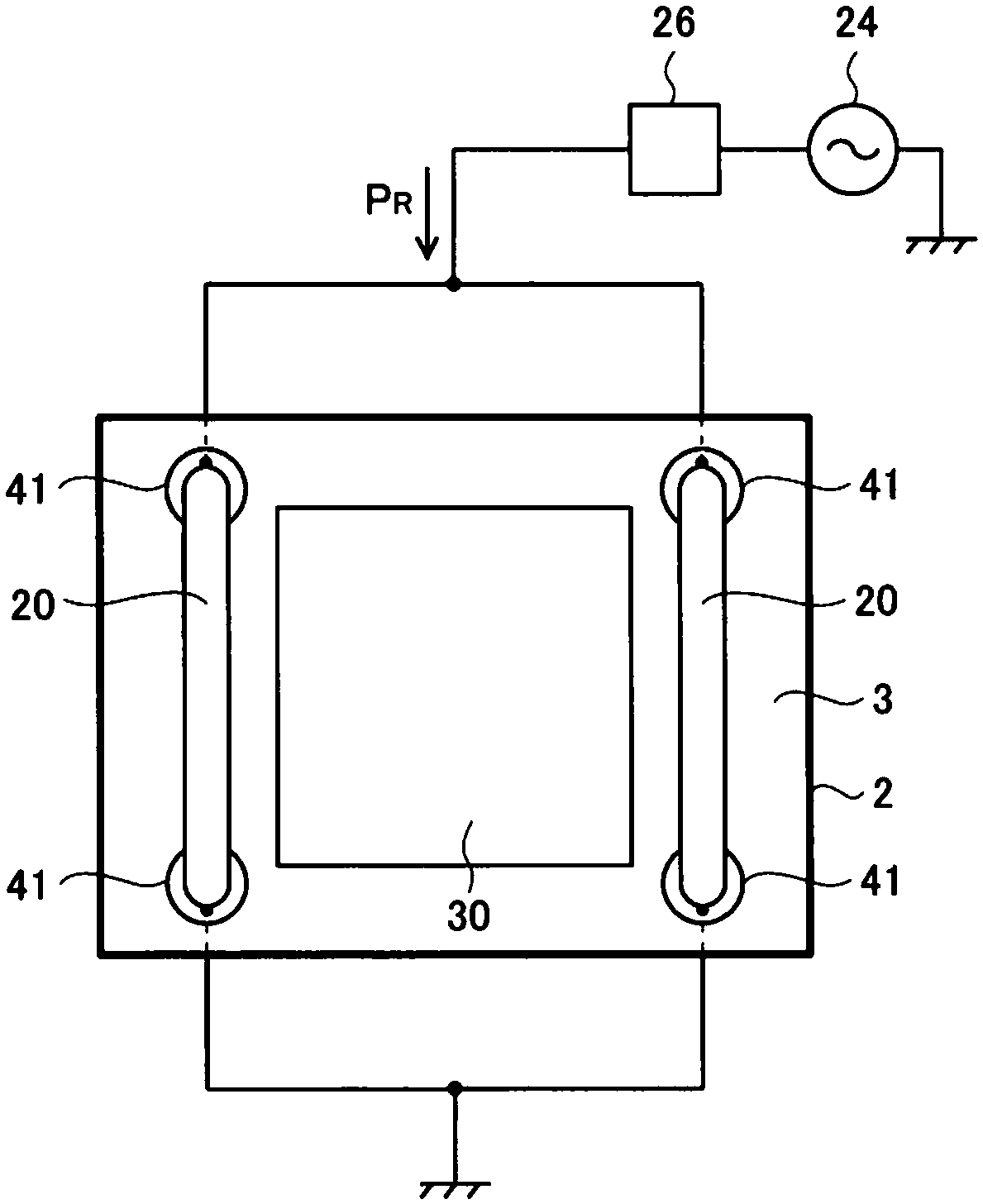

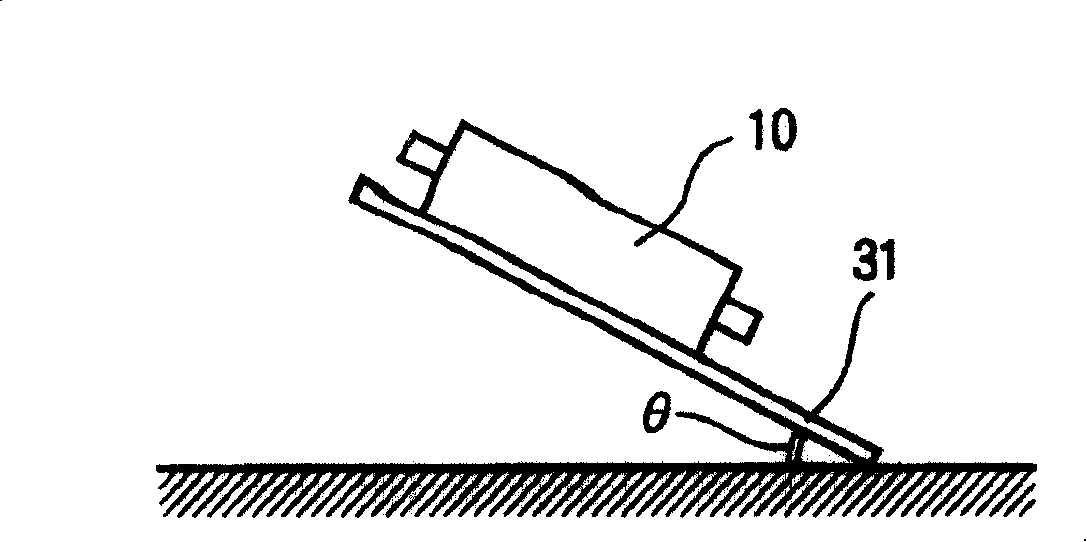

Deposition method and sputtering device

ActiveCN106715750APrevent filmingElectric discharge tubesVacuum evaporation coatingSputteringHigh frequency power

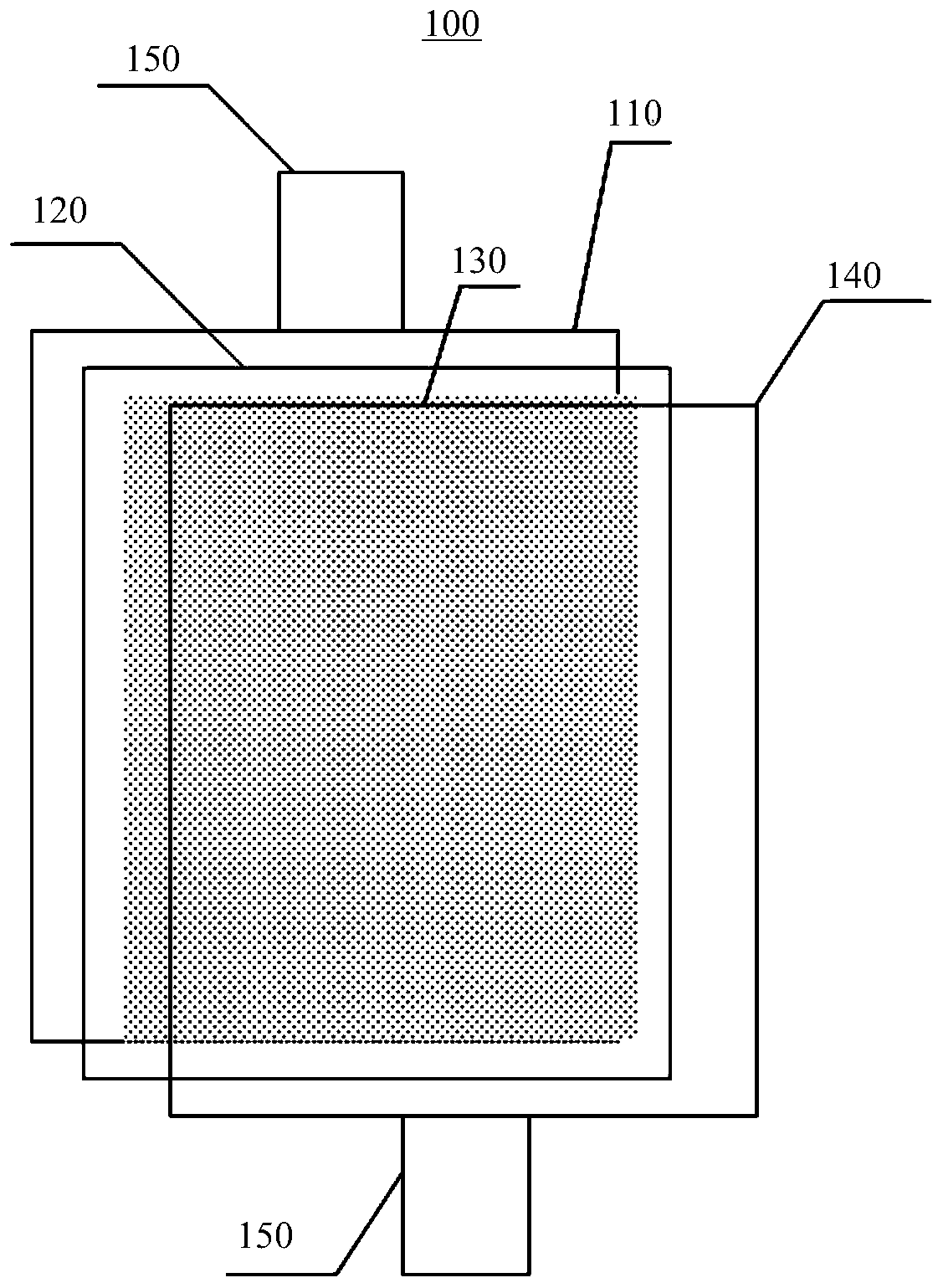

The purpose of the present invention is to prevent deposition of an uneven film at the start or end of film deposition without having to install a movement mechanism for a target. This sputtering device generates inductively coupled plasma (22) by supplying high-frequency power (PR) to an antenna (20) provided in a vacuum vessel (2) into which a gas (10) is introduced, and uses the plasma (22) and a target bias voltage (VT) to sputter a target (30) and deposit a film on a substrate (12). At the start of film deposition, the target bias voltage (VT) is applied to the target (30) to initiate sputtering after the high-frequency power (PR) has been supplied to the antenna (20) and the plasma (22) has been generated, and at the end of film deposition, the target bias voltage (VT) applied to the target (30) is stopped to stop sputtering, after which the high-frequency power (PR) supplied to the antenna (20) is stopped to quench the plasma (22).

Owner:NISSIN ELECTRIC CO LTD

Dry-process fine silica particle

InactiveCN101454246AGood dispersionGood interstitial permeabilitySilicaDevelopersMicroparticleWavelength

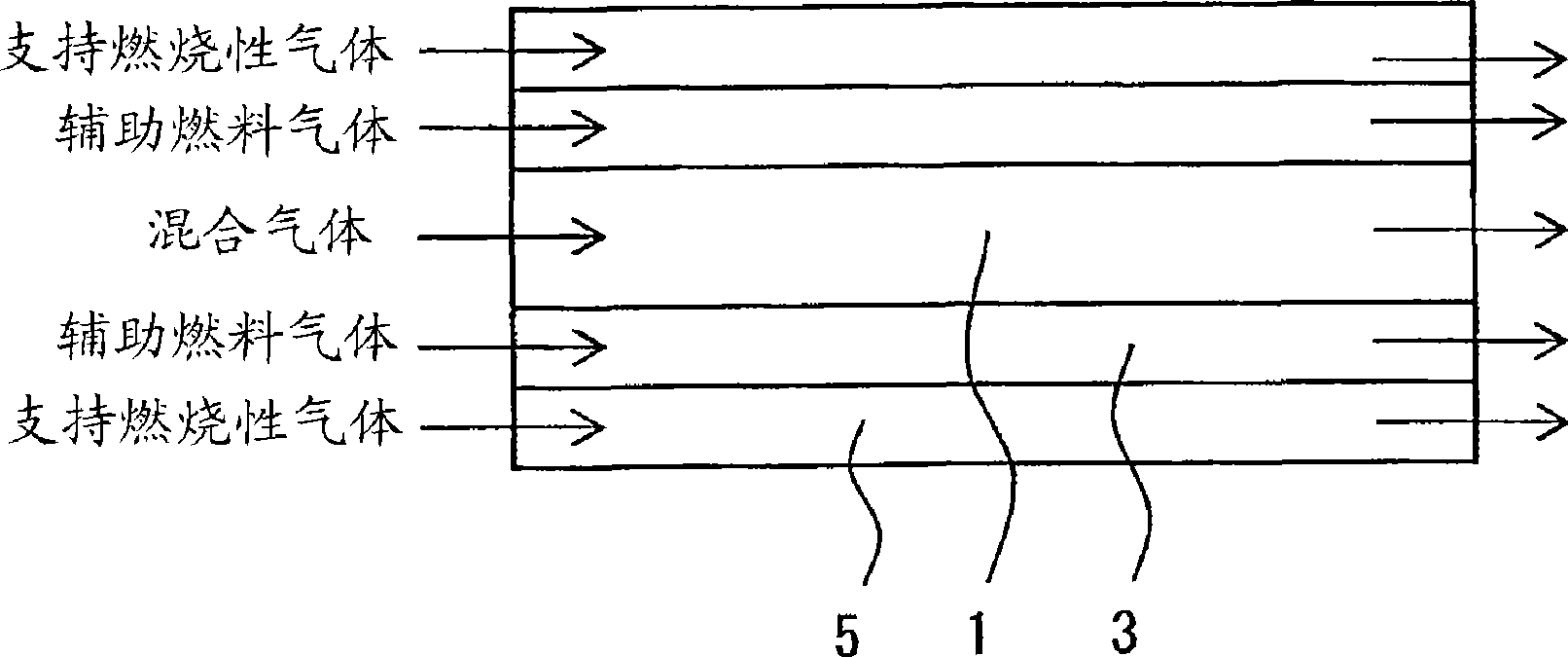

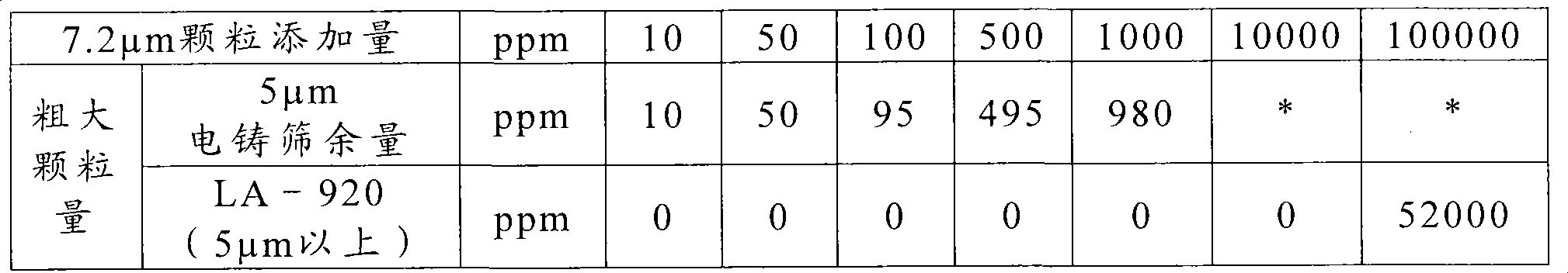

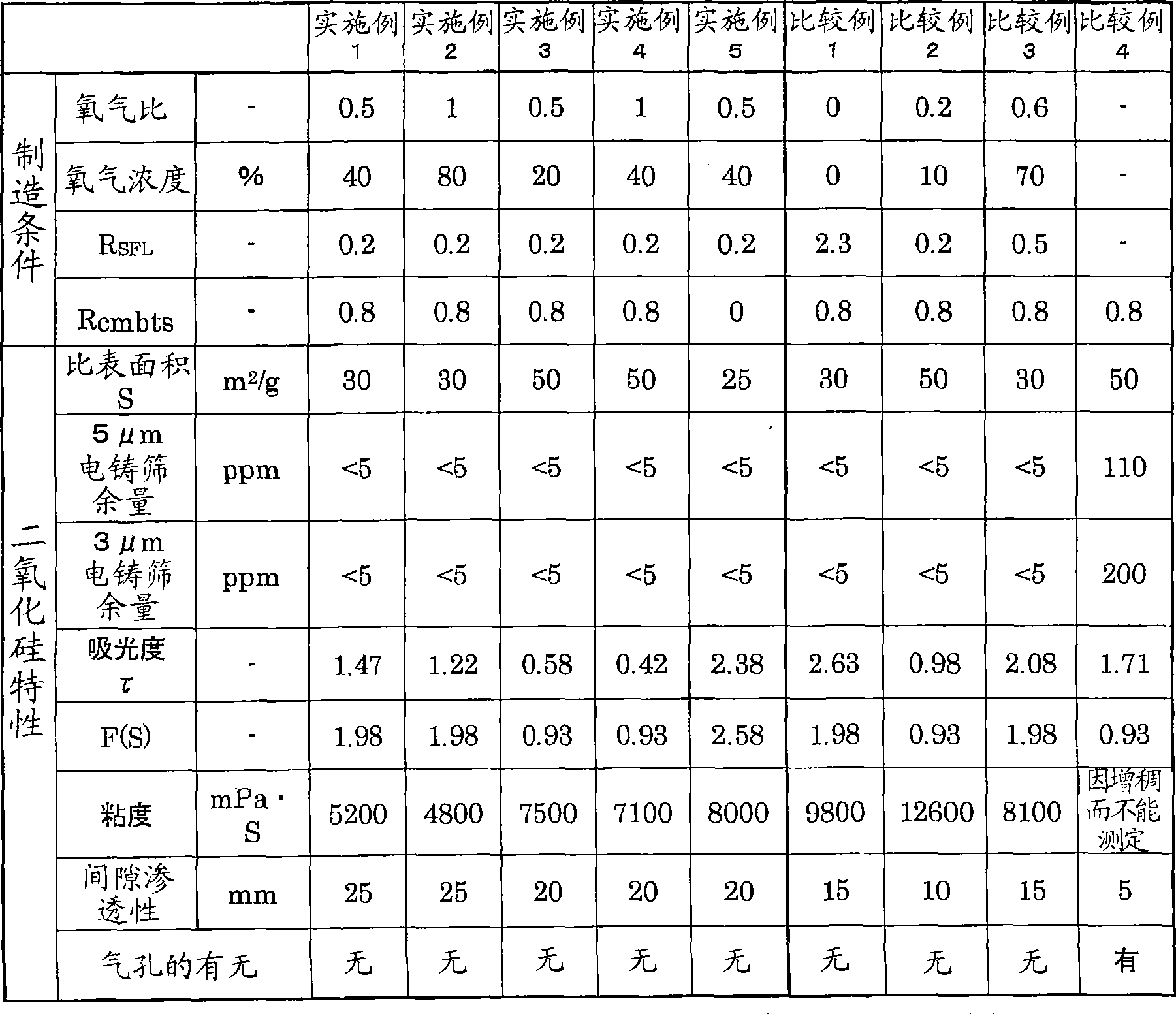

Fine dry silica particles are produced by combustion by using a burner of a multiple-pipe structure, feeding a mixed gas of a gas of a siloxane compound without containing halogen in the molecules thereof and an oxygen gas at a ratio of 0.3 to 1.5 into the center pipe of a burner, and feeding a combustible gas into the first annular pipe on the outer side of the center pipe of the burner. The fine dry silica particles has a BET specific surface area of 20 to 55 m 2 / g, and wherein the water suspension containing the fine silica particles at a concentration of 1.5% by weight has an optical absorbance for the light of a wavelength of 700 nm satisfying the following formula (1): wherein S is the BET specific surface area (m 2 / g) of the fine dry silica particles. The fine dry silica particles do not almost contain coarse particles or aggregated particles, have a sharpe grain size distribution, excellently disperse in the resins, suppress a rise in the viscosity when highly filled, and impart sufficiently large strength to the resin compound.

Owner:TOKUYAMA CORP

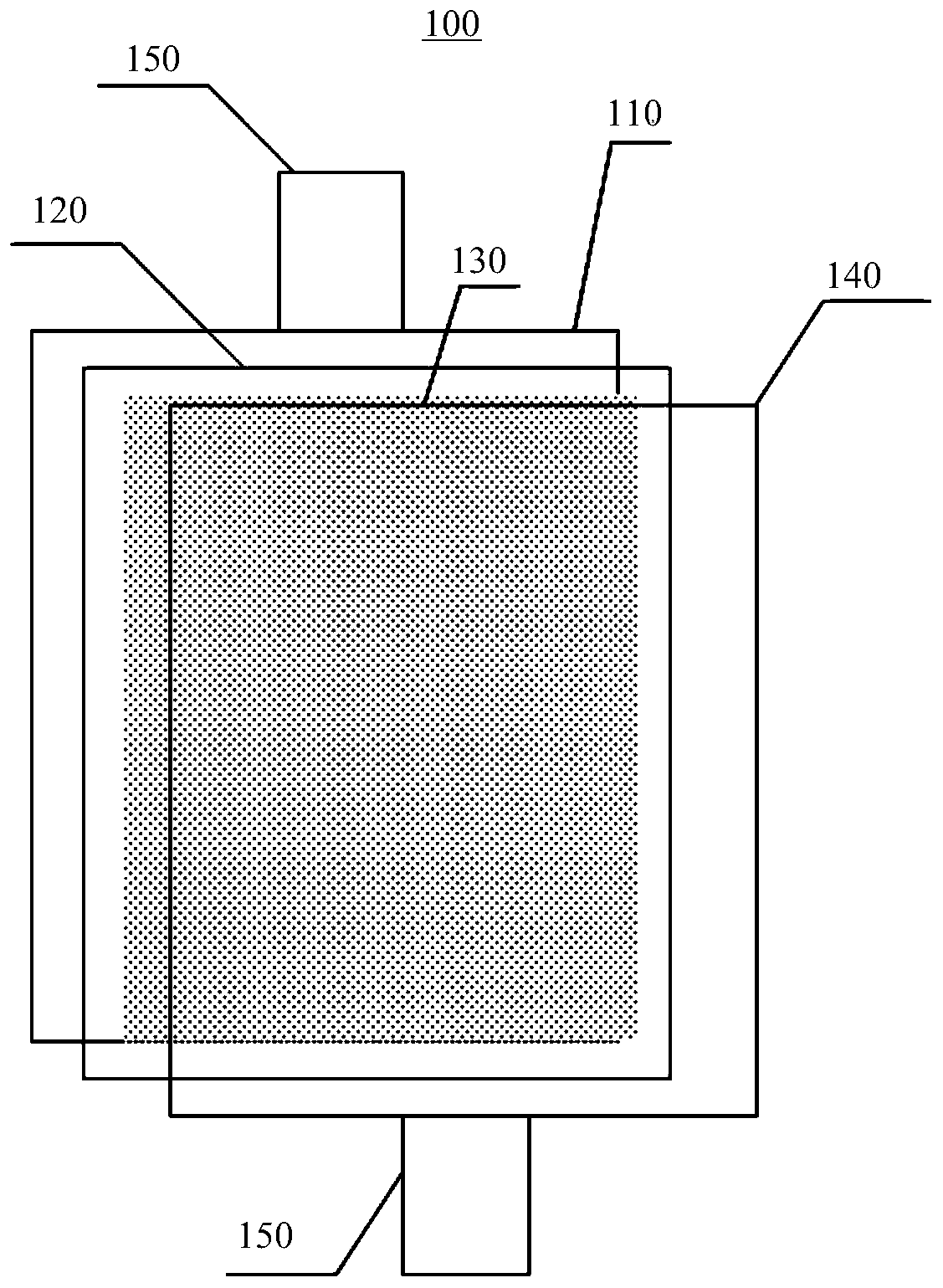

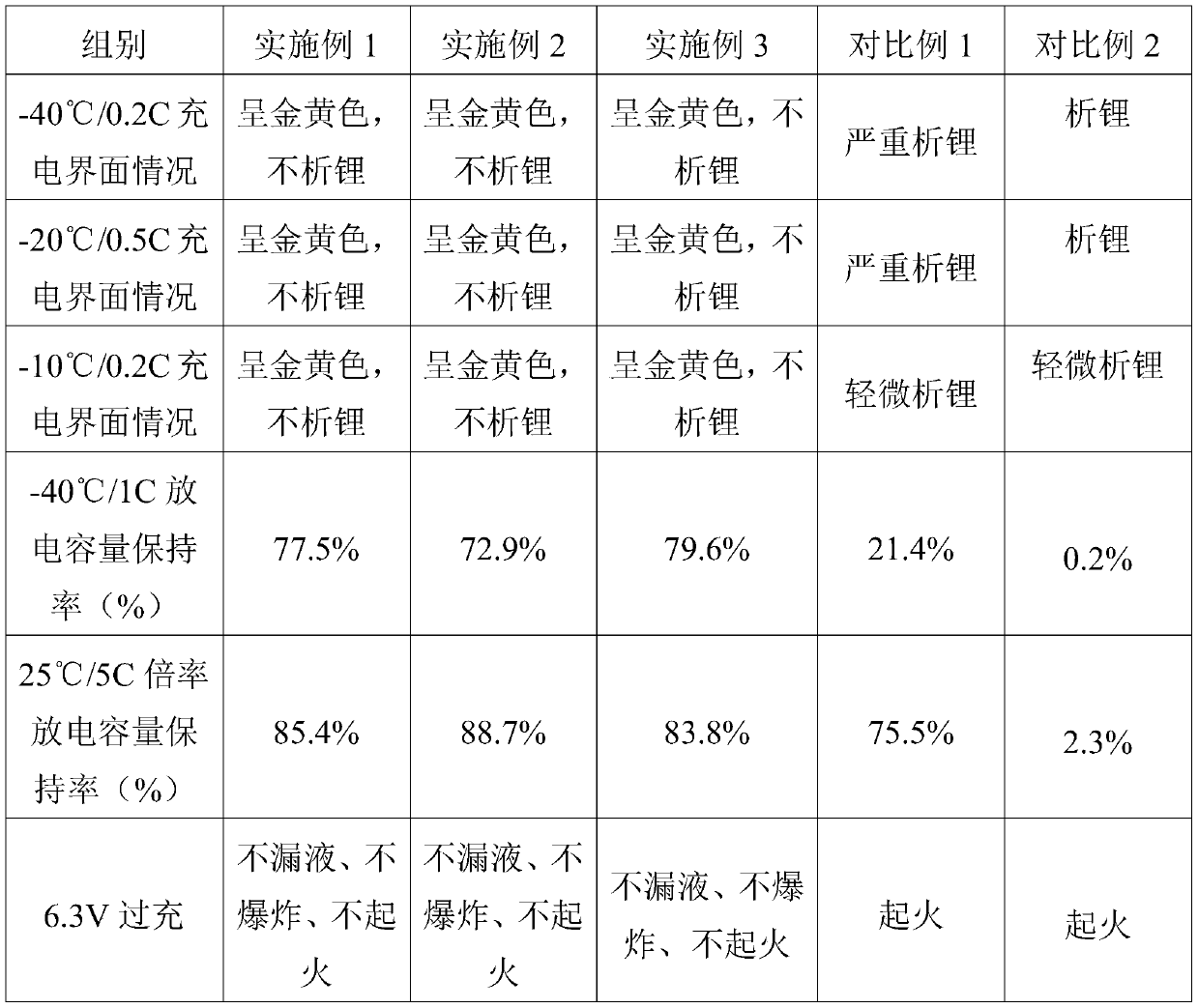

Lithium battery positive electrode material, preparation method thereof, lithium battery, and positive electrode piece of lithium battery

InactiveCN109713264AImprove Interface StabilityInhibit corrosionCell electrodesSecondary cellsElectrically conductiveSide reaction

The invention relates to a lithium battery positive electrode material, a preparation method thereof, a lithium battery and a positive electrode piece of the lithium battery. The lithium battery positive electrode material comprises a lithium active material, and the outer surface of the lithium active material is coated with a composite conductive layer, wherein the composite conductive layer isformed by compounding a conductive polymer adhesive and conductive carbon according to a mass ratio of 1: (0.8-1.2). The composite conductive layer can be used as a protective layer, thereby improvingthe interface stability of the positive electrode material, preventing the anode material from being corroded by the electrolyte, preventing side reaction products generated with the electrolyte frombeing accumulated on the surface of the positive electrode, and avoiding the decrease of the lithium diffusion speed and transfer rate of charges between the electrodes and an electrolyte interface.Meanwhile, the composite conductive layer can form an excellent conductive network and an excellent conductive node, so the conductive performance is excellent, the transmission resistance of lithiumions in an electrode material is reduced, and the low-temperature performance of the lithium ion battery is improved.

Owner:SOUNDON NEW ENERGY TECH CO LTD

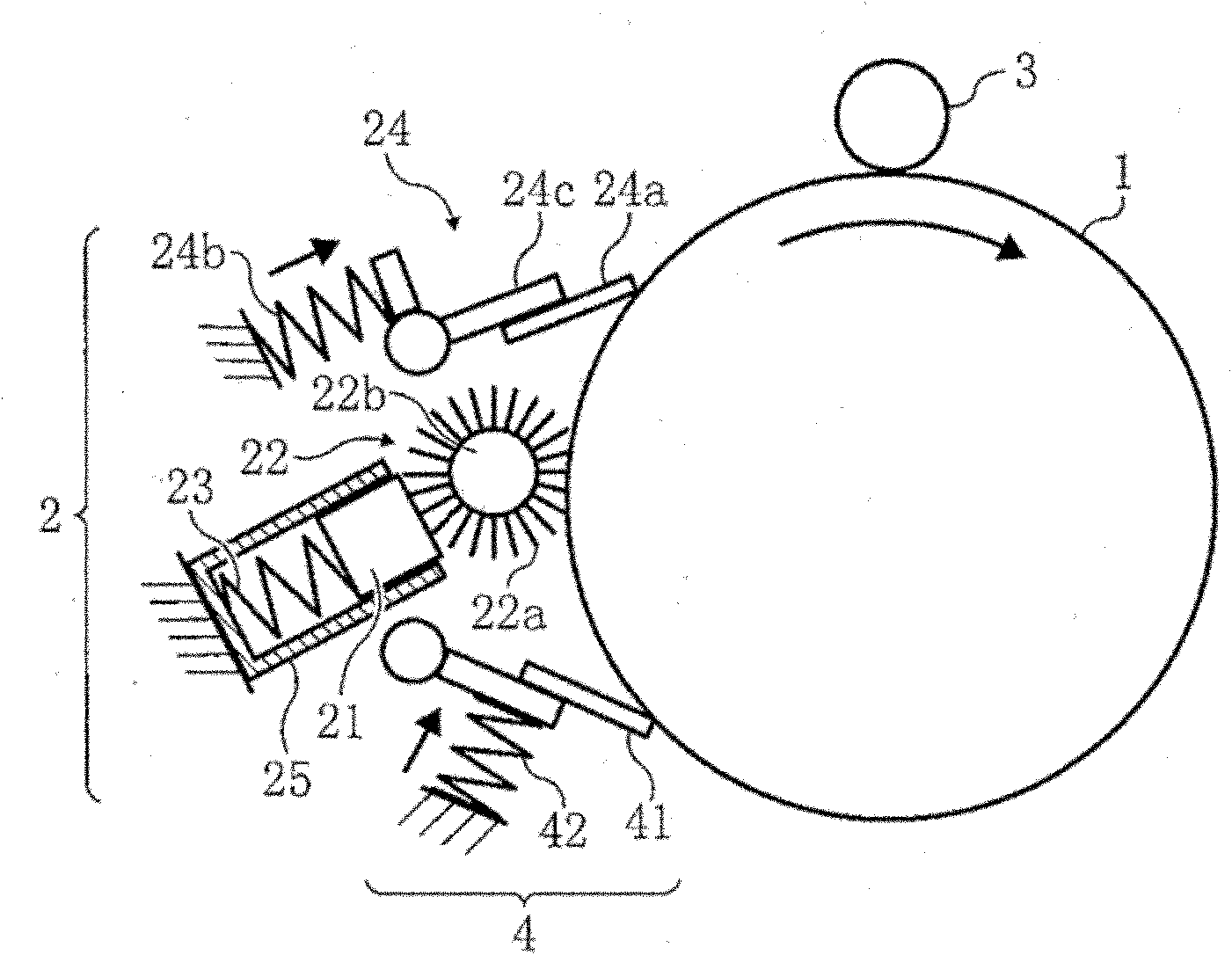

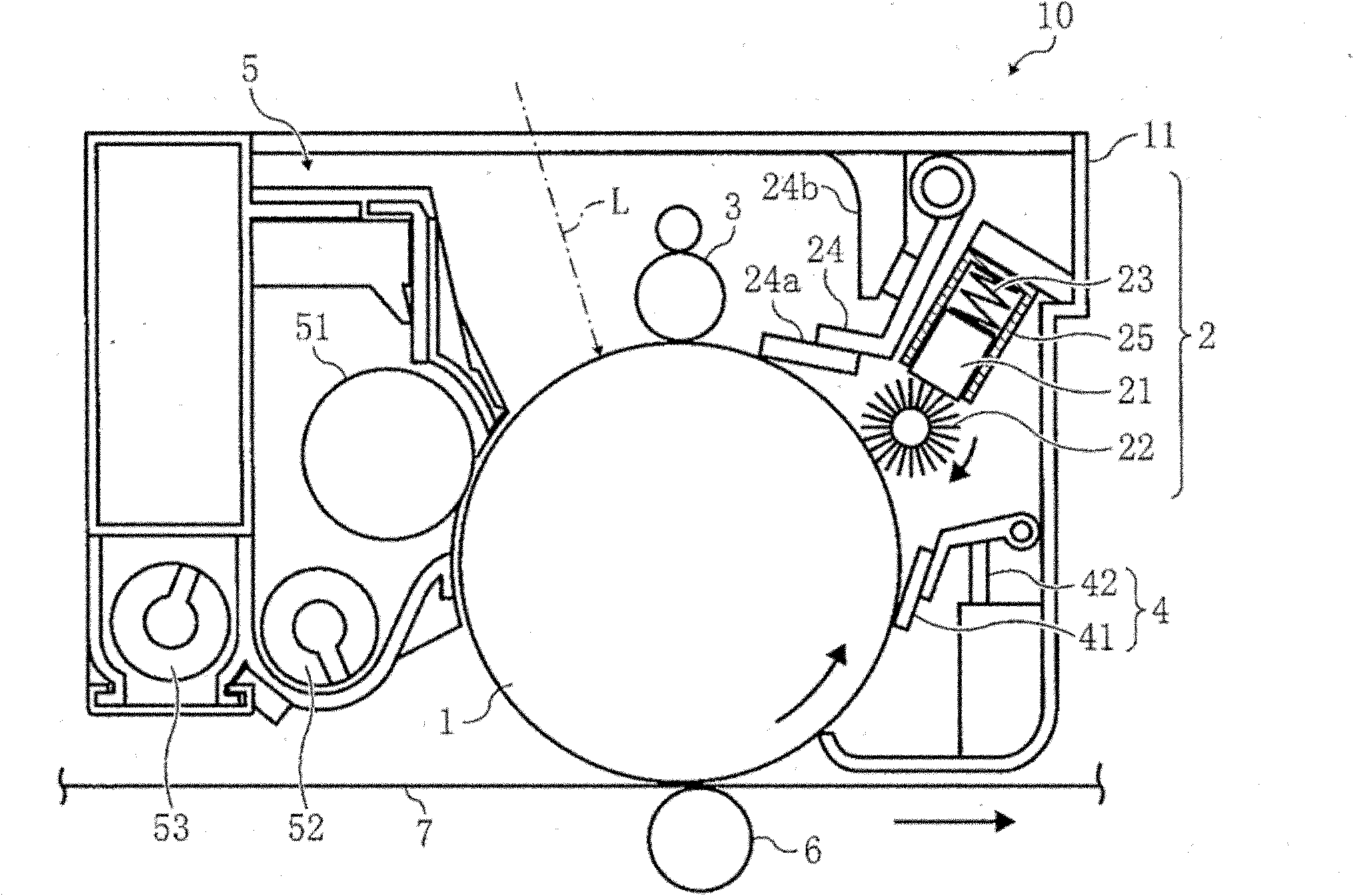

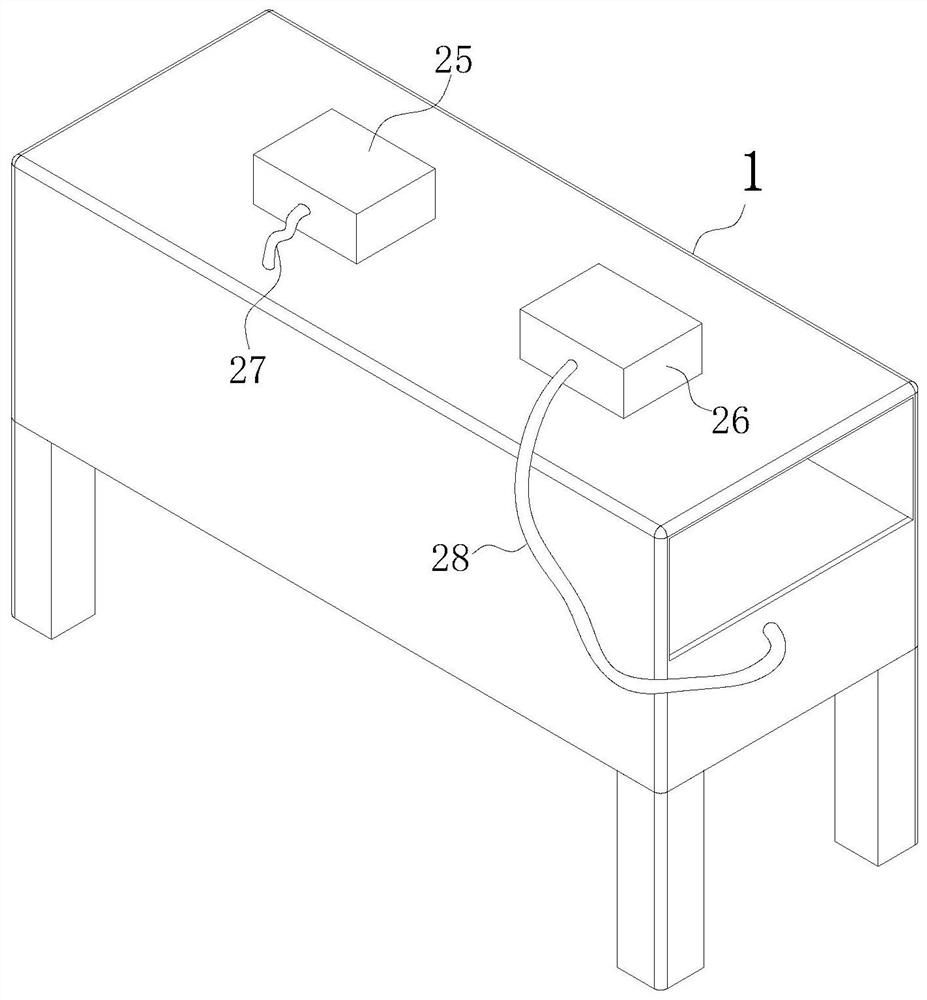

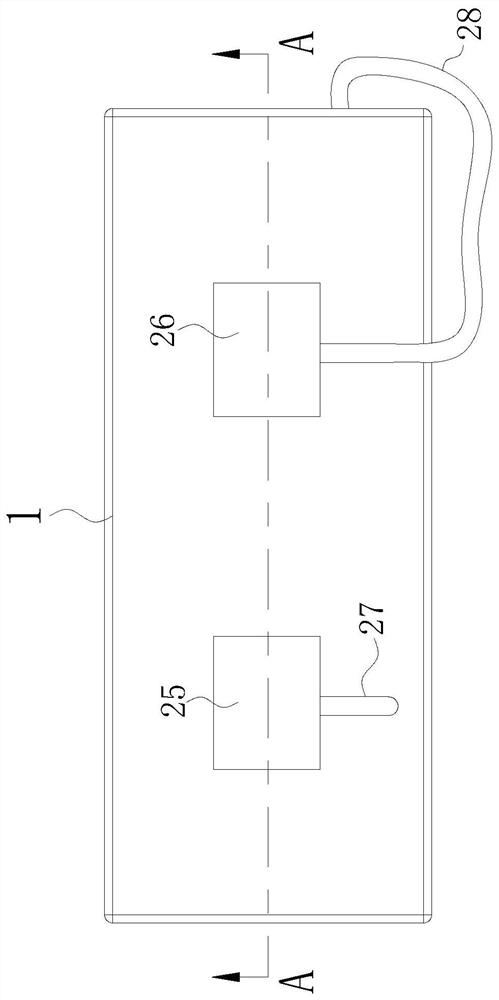

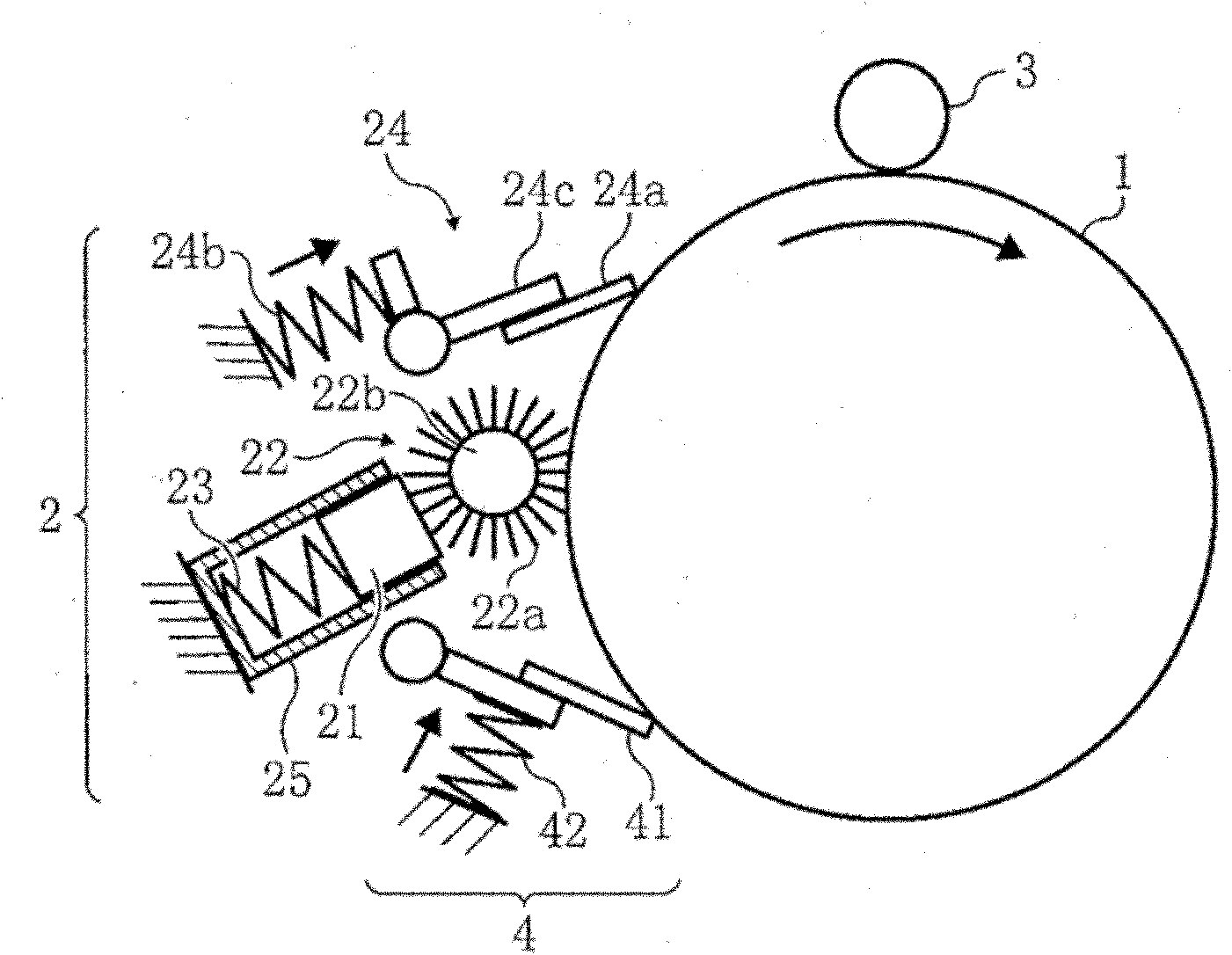

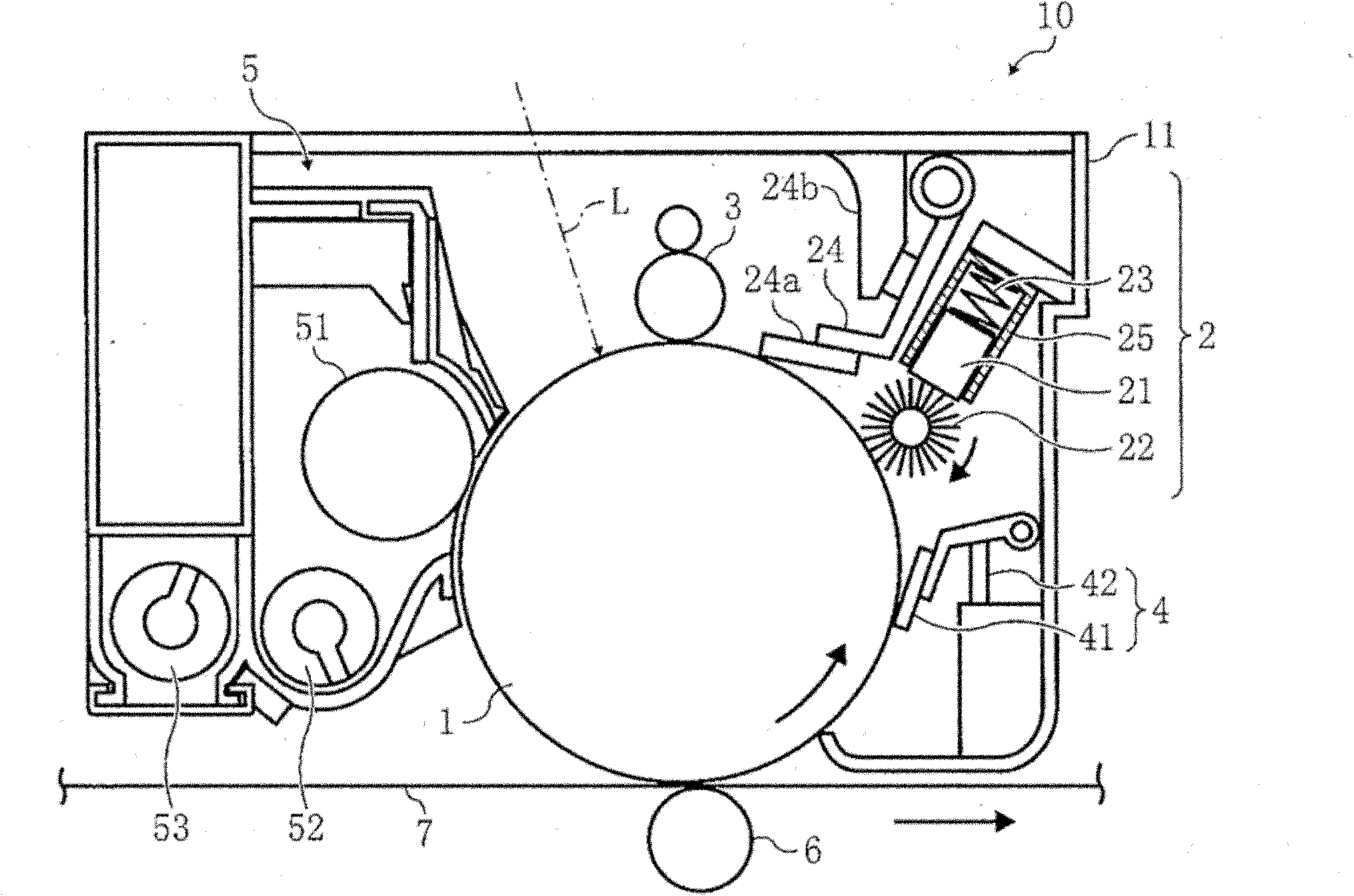

Image-bearing member protecting agent, protective layer forming device, image forming method, image forming apparatus, and process cartridge

ActiveCN102129205AFully protectedPrevent filmingElectrographic process apparatusLubricant compositionImage formationEngineering

To provide an image-bearing member protecting agent which can achieve a sufficient protecting effect on the surface of an image-bearing member, prevention of filming on the image-bearing member, and prevention of smearing on a charging member, and to provide a protective layer forming device which can form an excellent protective layer for image-bearing member using the image-bearing member protecting agent. The image-bearing member protecting agent to be used for an image forming method or an image forming apparatus is characterized by comprising the following components: a hydrophobic organic compound (A); an inorganic lubricant (B); and inorganic fine particles (C), wherein each of the inorganic fine particles (C) has a specific surface area of 2.0 to 6.5 m<2> / g. The protective layer forming device 2 includes at least an image-bearing member protecting agent 21 and a protecting agent supply member 22, and supplies the image-bearing member protecting agent 21 to the surface of the image-bearing member 1 via the protecting agent supply member 22.

Owner:RICOH KK

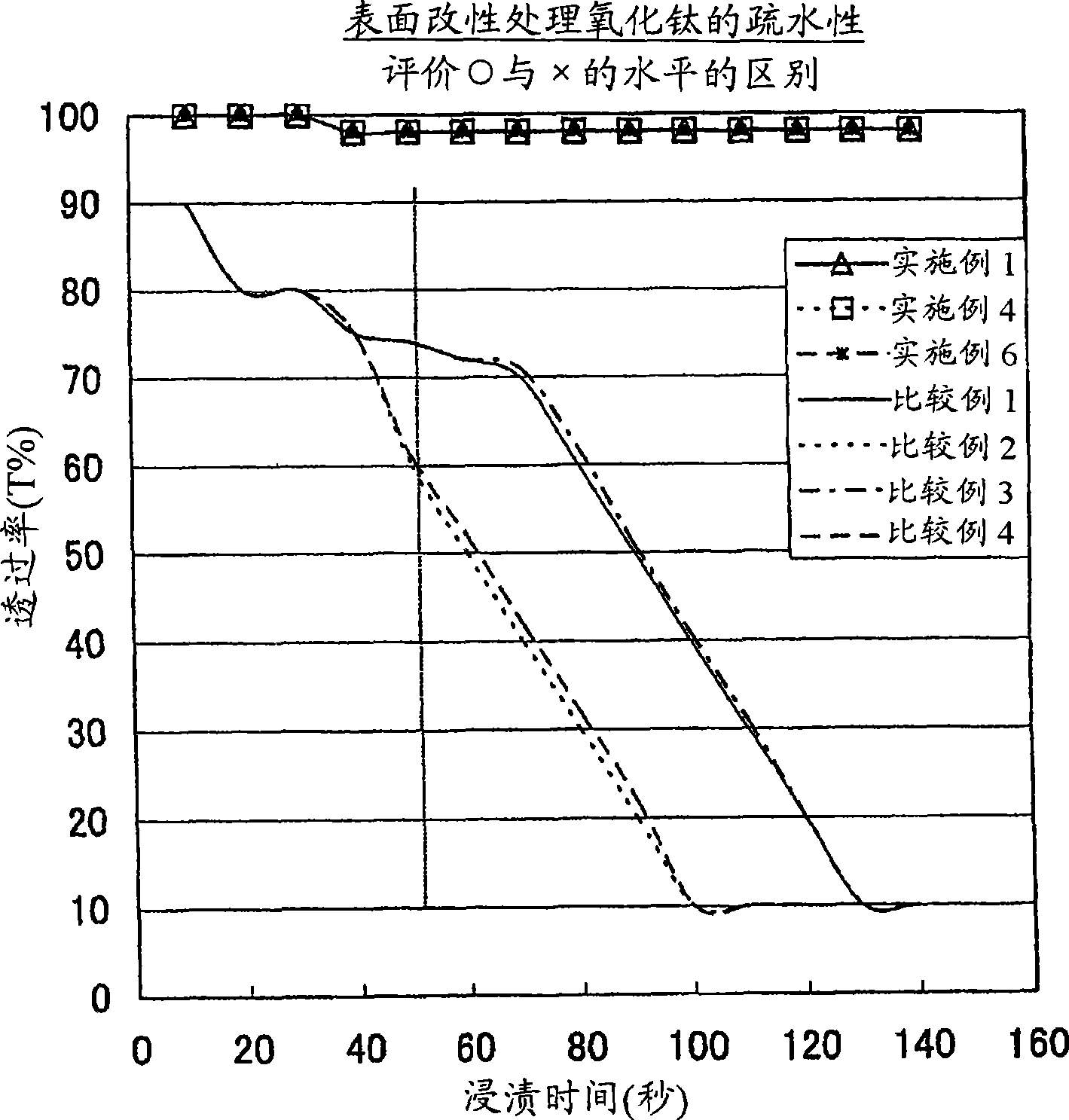

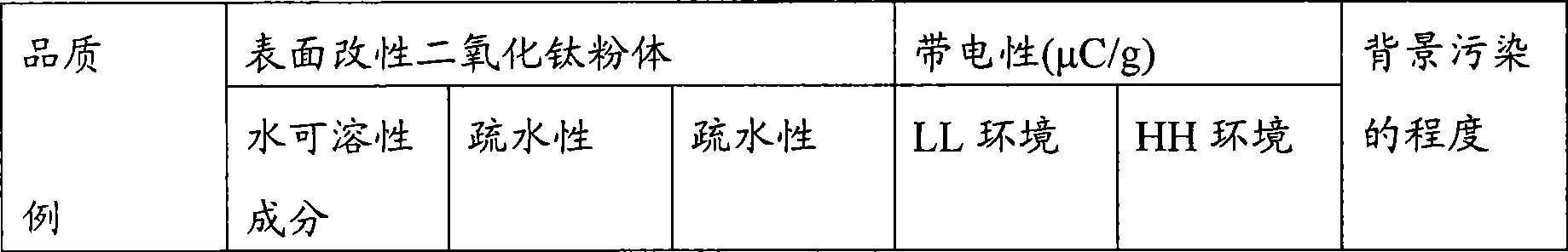

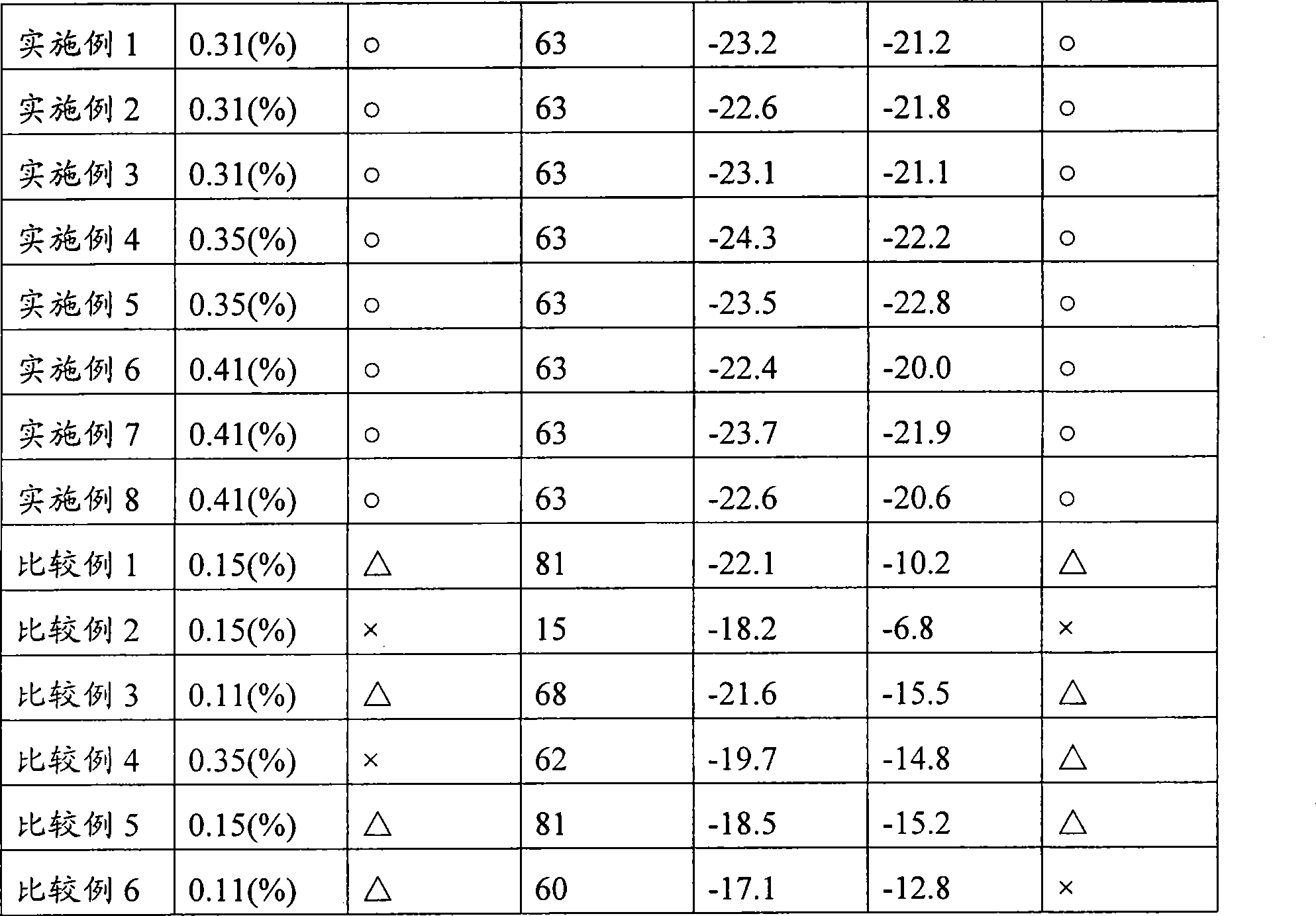

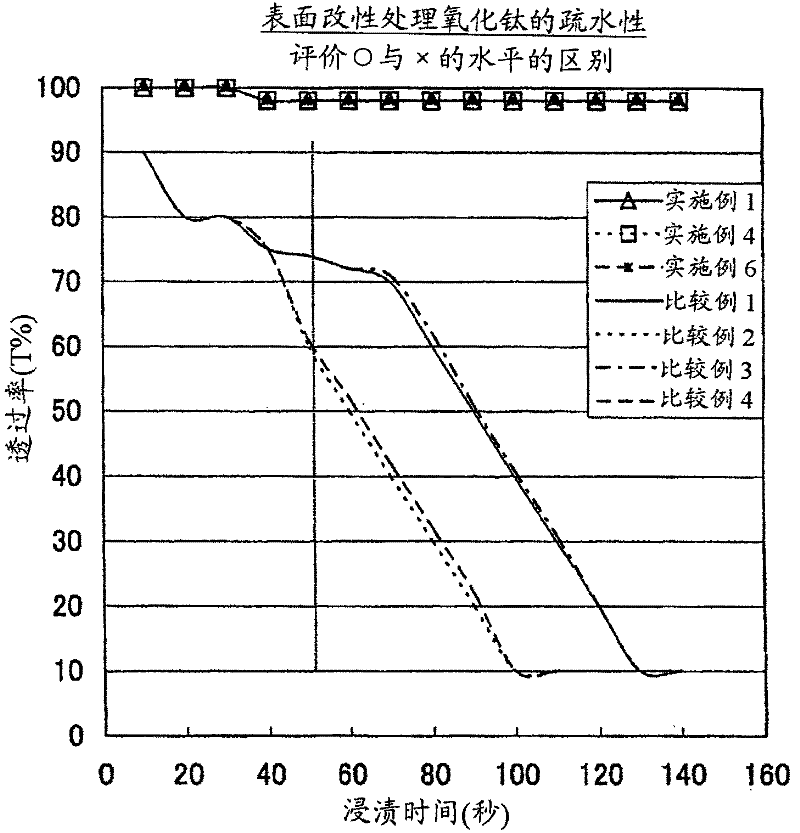

External additive, method of manufacturing same and toner

InactiveCN101424890AGood electrificationAppear lessPigmenting treatmentMaterial nanotechnologySilane compoundsSilanes

The invention provides a titanium dioxide external additive which is capable of being controlled stably, maintaining frictional charging amount, having less ambient variation, maintaining stable frictional charging performance, and which is free from abnormal images resulted from attachment of a toner to a photoreceptor that is generated while image developing and subjected to a surface modification treatment. The invention also provides an electrostatic charge images developing toner that is externally added with the external additive and an image forming method using the electrostatic charge images developing toner. The inventive external additive has the characteristic that particle surface of titanium dioxide having a water-soluble component of more than 0.2% is modified by the fluorosilane compound.

Owner:RICOH KK

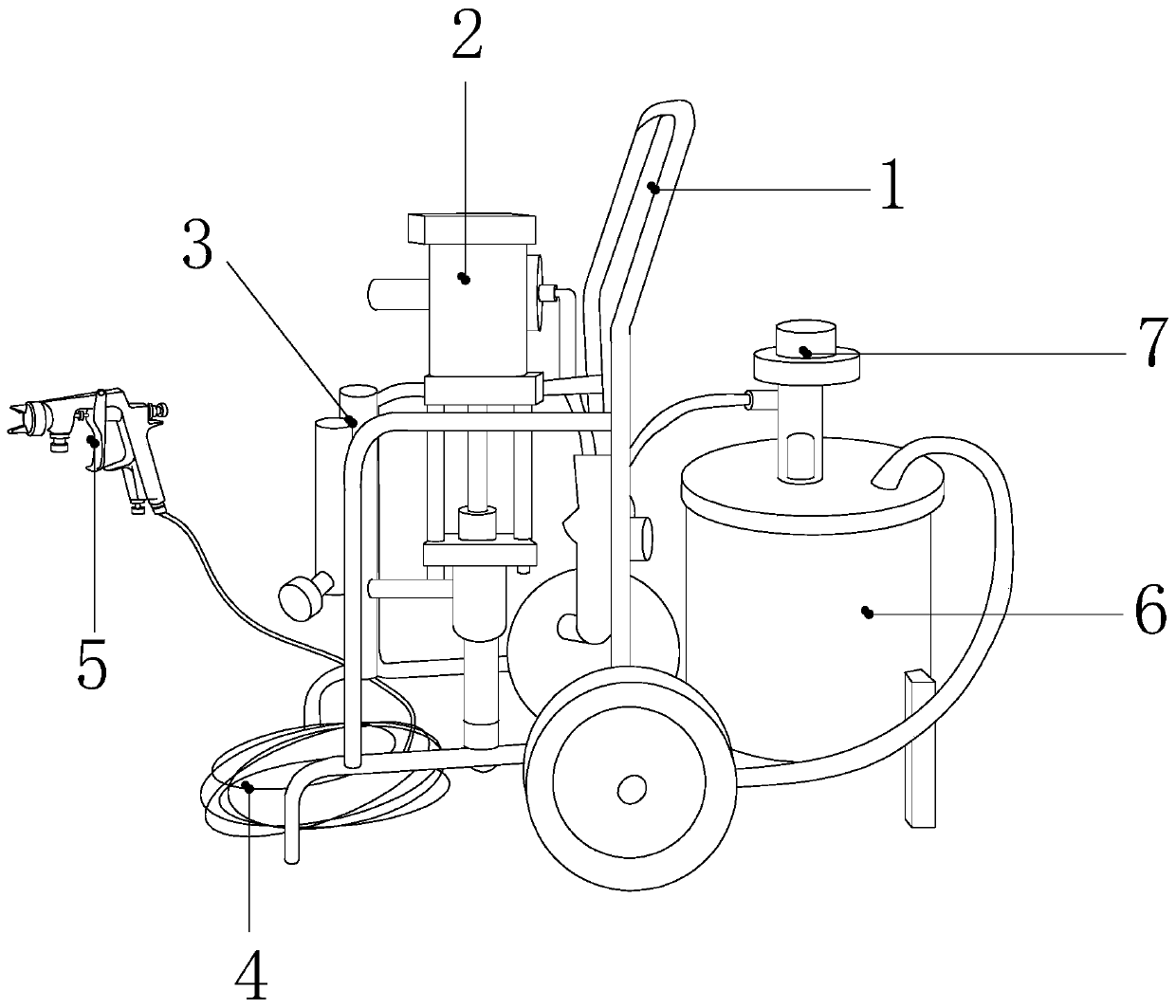

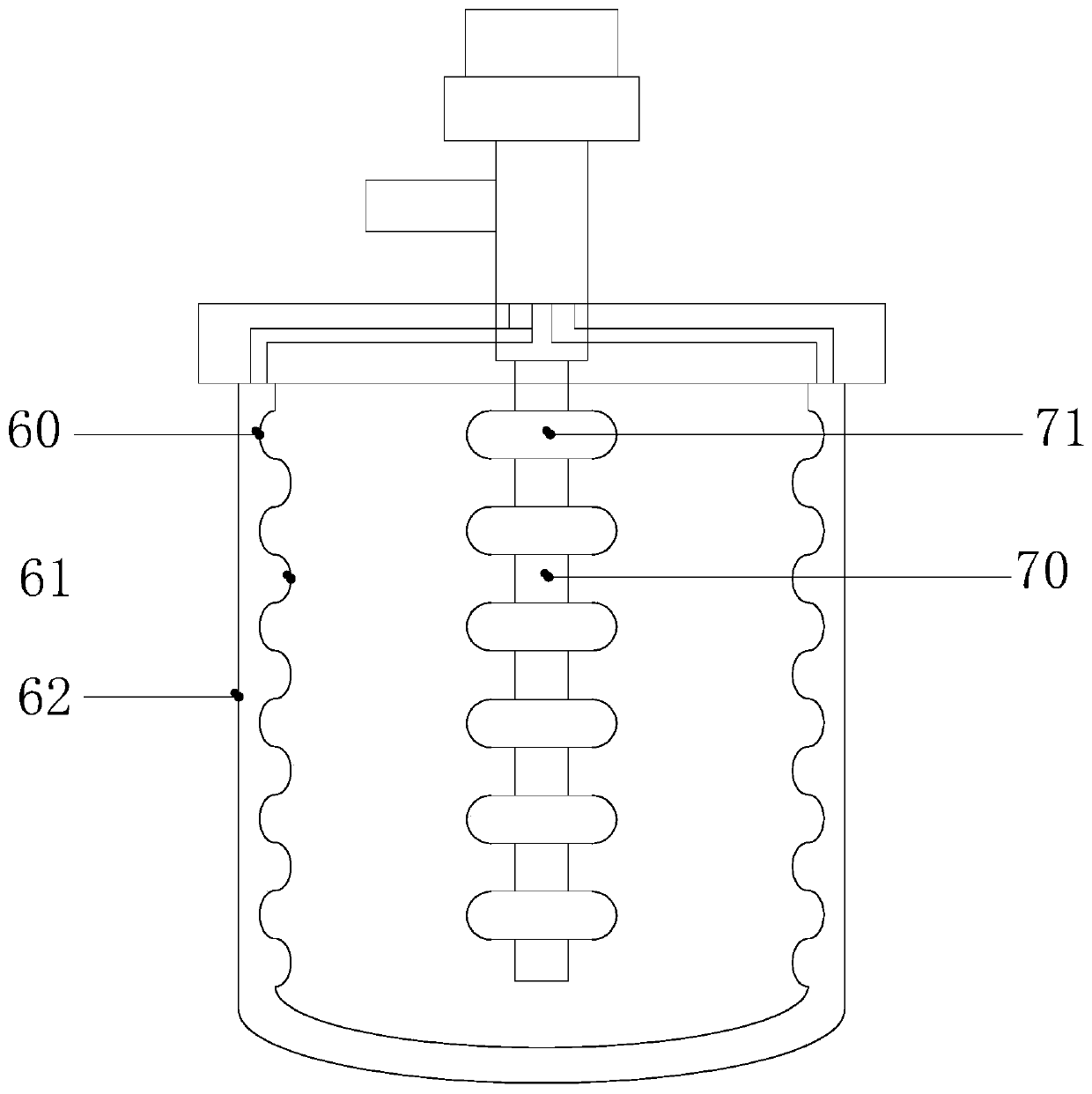

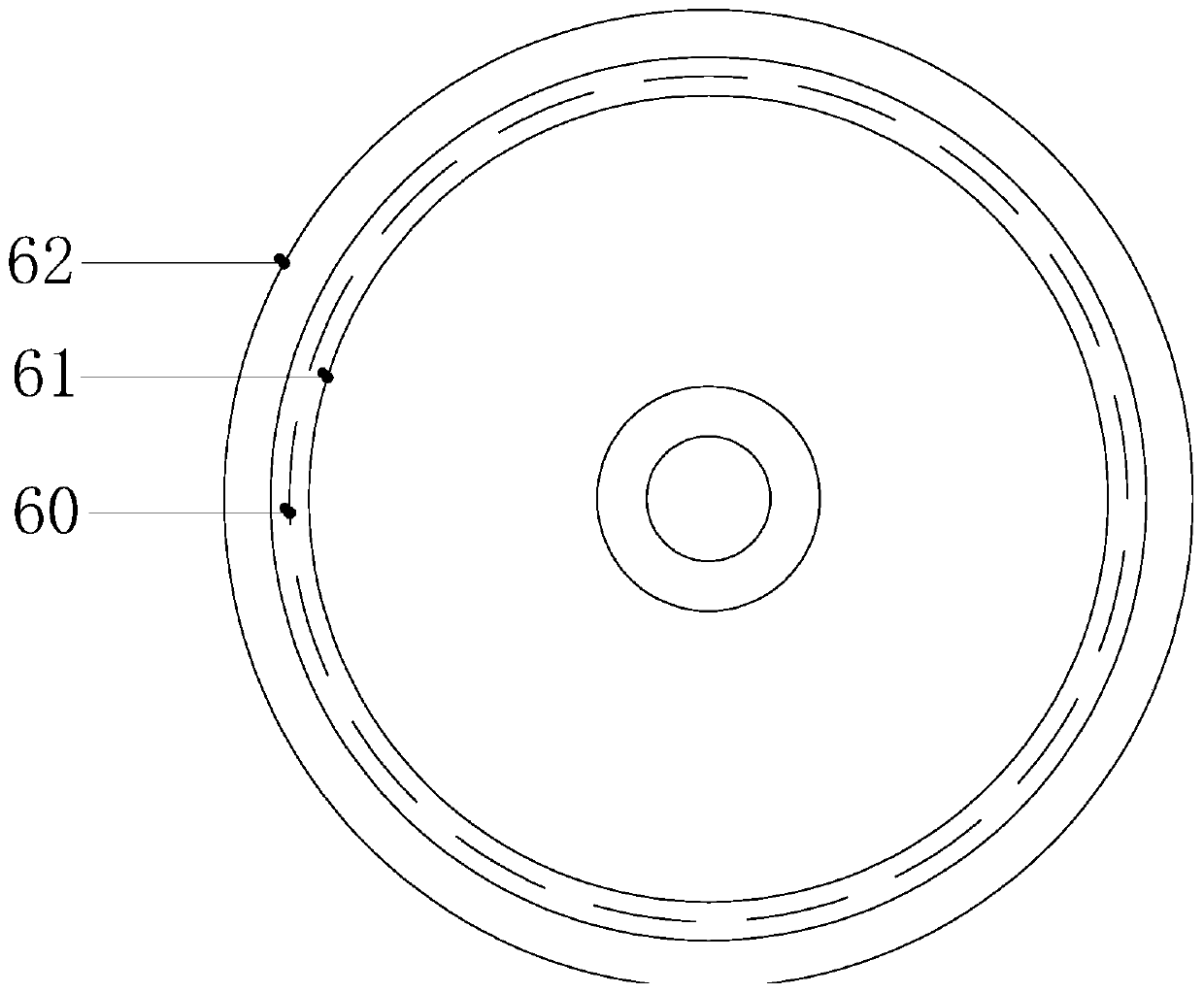

Steel bar spraying equipment for wave-type anti-stirring bridge

The invention discloses steel bar spraying equipment for a wave-type anti-stirring bridge. The steel bar spraying equipment structurally comprises a trolley, an air compressor, a filter pressure stabilizer, an air pipe, a spray gun, a material storage barrel and a pneumatic stirrer. The steel bar spraying equipment has the beneficial effects that a wave structure composed of an auxiliary anti-stirring mechanism and an anti-sticking plate is utilized to enable paint of the barrel wall to be quickly dropped under the action of gravity in the use process of the paint, so that the phenomenon thata paint film or caking occurs on the wall of the barrel wall in a large area is avoided; the auxiliary anti-stirring mechanism is used for intensively blowing the oil paint into the center of the barrel in parallel, an inner concave arc-shaped plate and a flat round-shaped body are located on the same horizontal line, and when the paint touches the flat round body under the action of air pressure,the paint is scattered to the two sides to be reversely stirred so as to reduce the bubbles inside the paint; and the rotation of a pneumatic stirrer and the horizontal line of the auxiliary anti-stirring mechanism are utilized, so that the oil paint is mixed and stirred under the cooperation of two strands of force, the paint is more uniform, and the air pressure generated by the auxiliary anti-stirring mechanism enables the oil paint to diffuse towards two sides to reduce air bubbles inside the paint when the paint touches the flat round body.

Owner:潘晓青

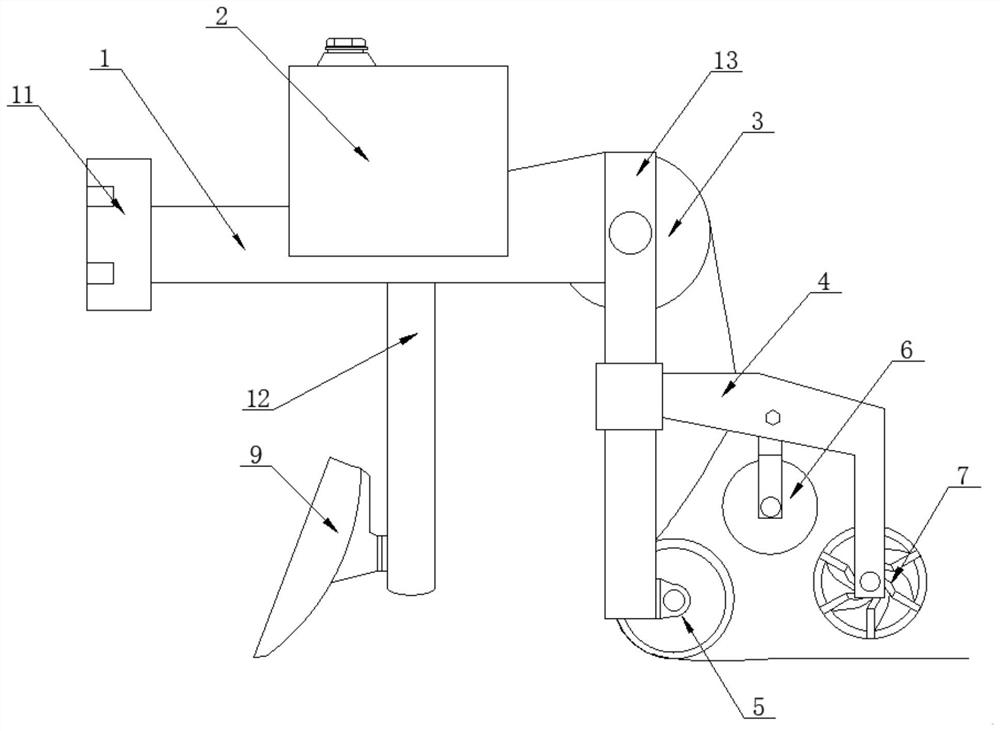

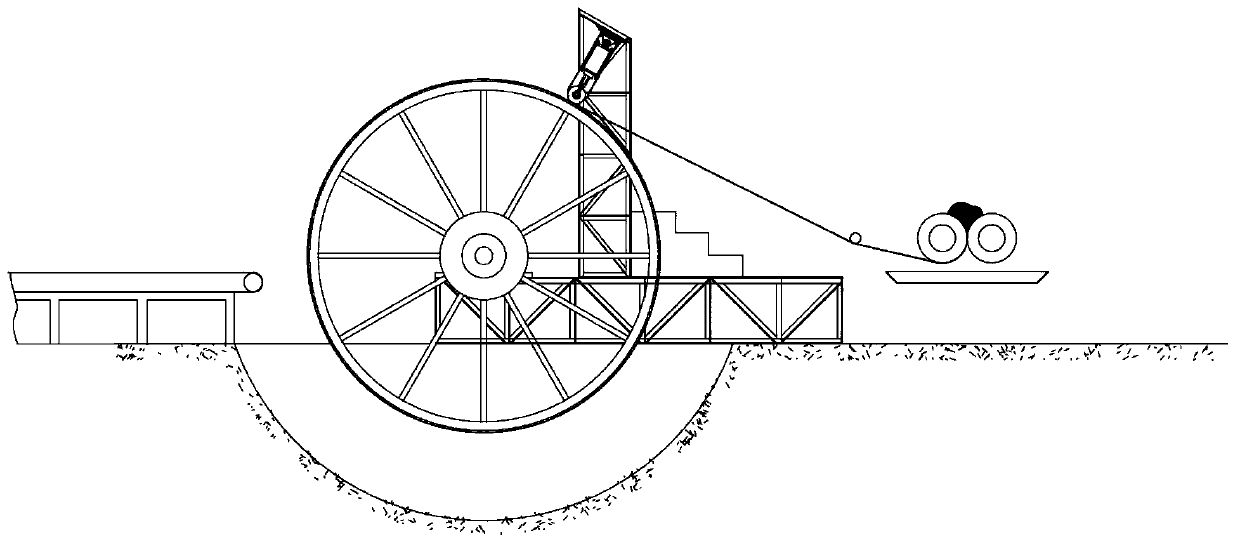

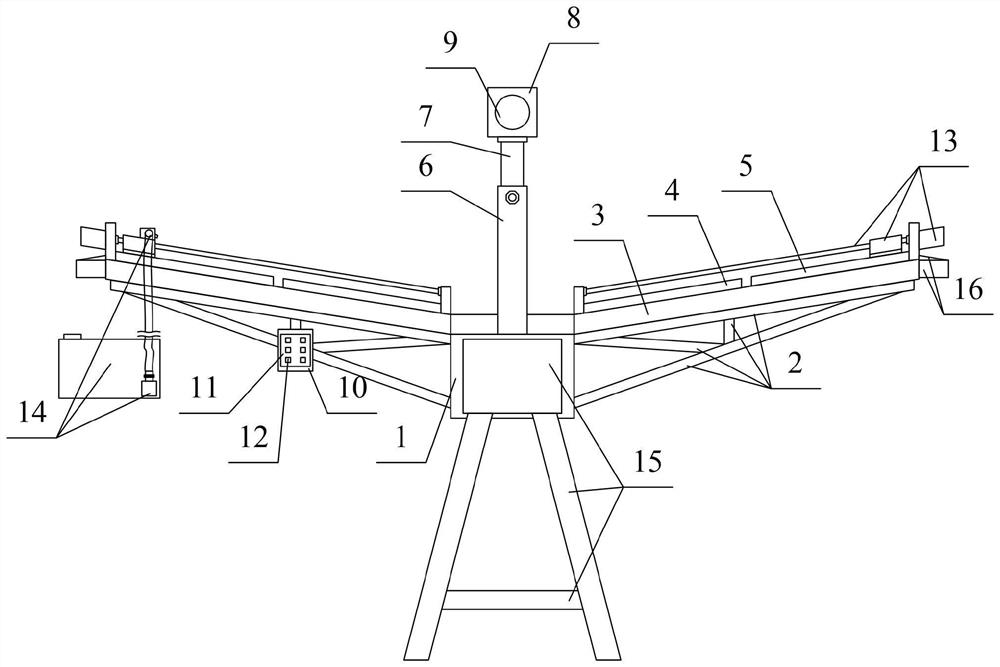

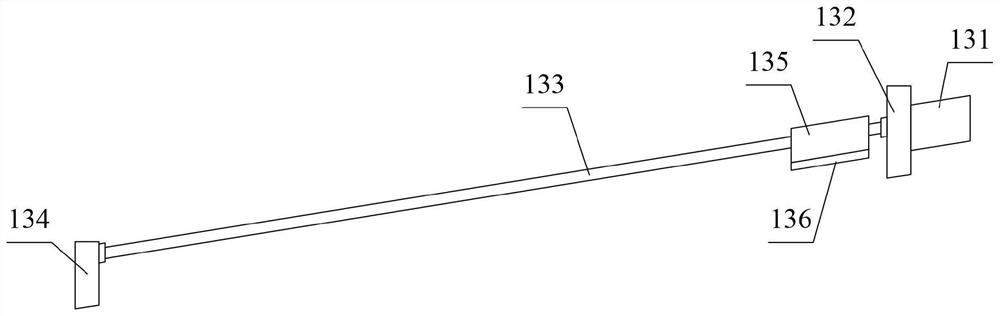

Automatic film mulching equipment for potato planting for smart agriculture

InactiveCN112690157AAutomate operationSimple structurePlantingPressurised distribution of liquid fertiliserAgricultural engineeringStructural engineering

The invention discloses automatic film mulching equipment for potato planting for smart agriculture, and particularly relates to the field of intelligent agriculture. The equipment comprises a traction connecting rod; the other end of the traction connecting rod is fixedly provided with a film mulching mounting frame; the bottom surface of the traction connecting rod is fixedly provided with an adjustable plow arm; the surface of the adjustable plow arm is provided with a lifting sliding groove; a film mulching slotting mechanism is slidably mounted at the inner side of the lifting sliding groove; a nutrient solution box is mounted on the top face of the traction connecting rod; a spraying pipe is mounted at the inner side of the film mulching mounting frame; and the outer side of the film mulching mounting frame is movably connected with a sorting and mulching rack in a sleeving mode. By arranging a novel film mulching and soil covering structure, ditching and grooving are conducted at the two sides of an operation ridge through the film mulching slotting mechanism, the two sides of a planting film are pressed into grooves through film mulching pressing wheels, and soil covering and fixing treatment is conducted through soil covering rotating rollers, so that automatic operation of whole film mulching is achieved, the structure is simple, the two sides of the film are fixed more tightly through a slotting type film pressing structure, and the film stripping phenomenon caused by the severe environment is prevented.

Owner:马群

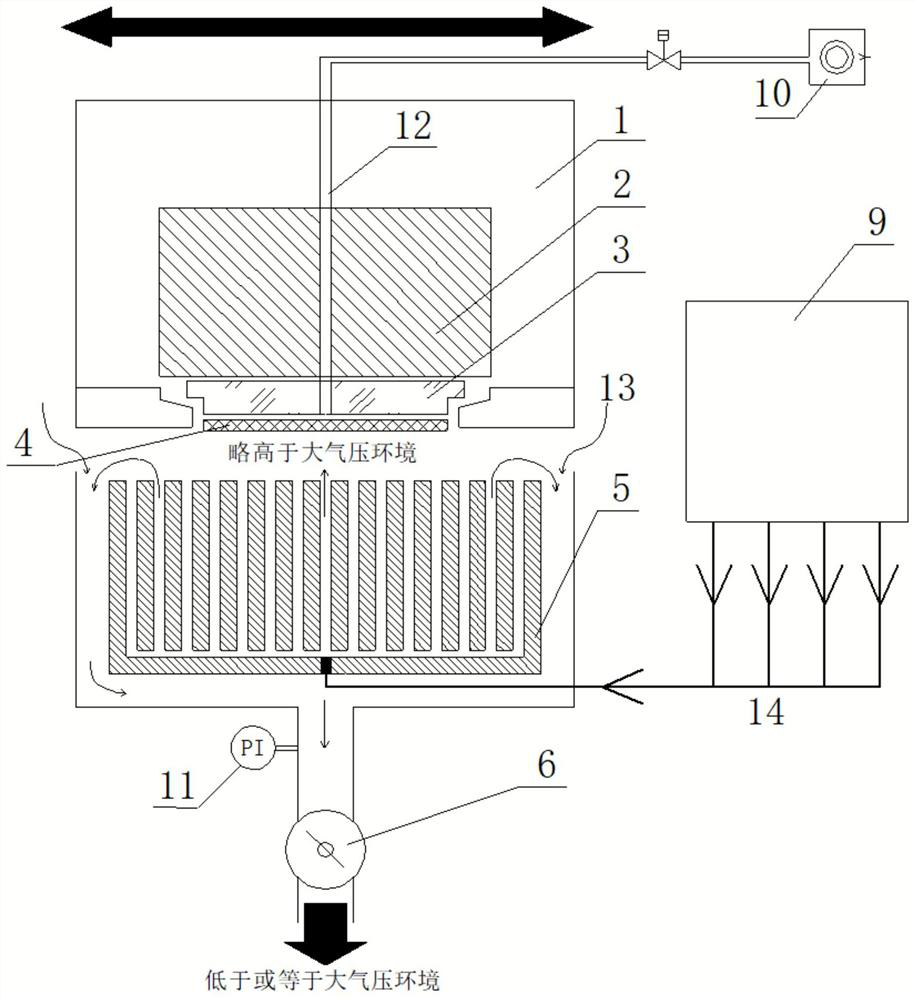

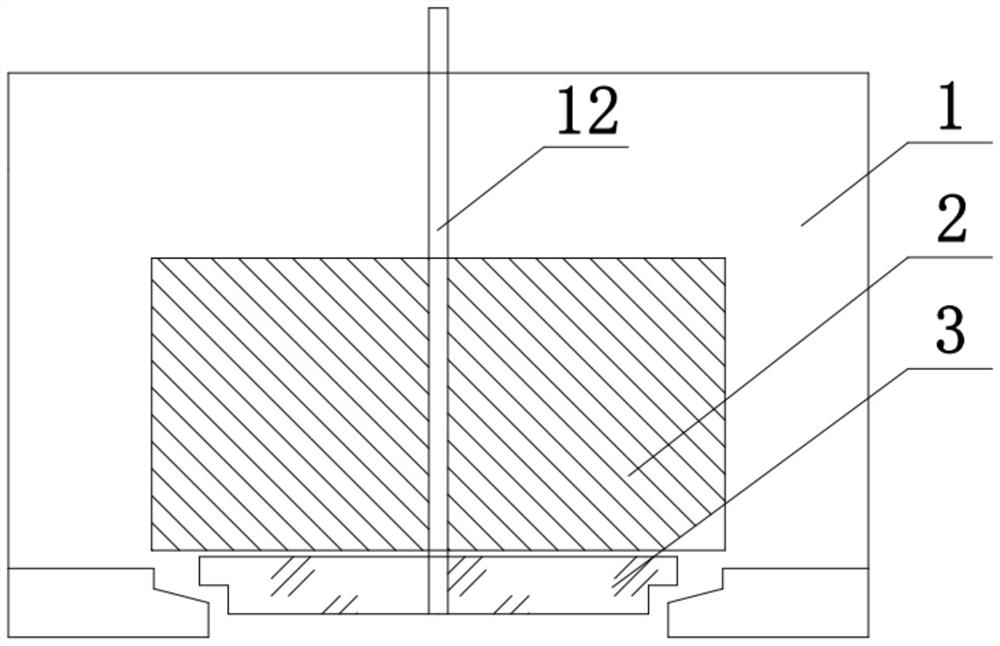

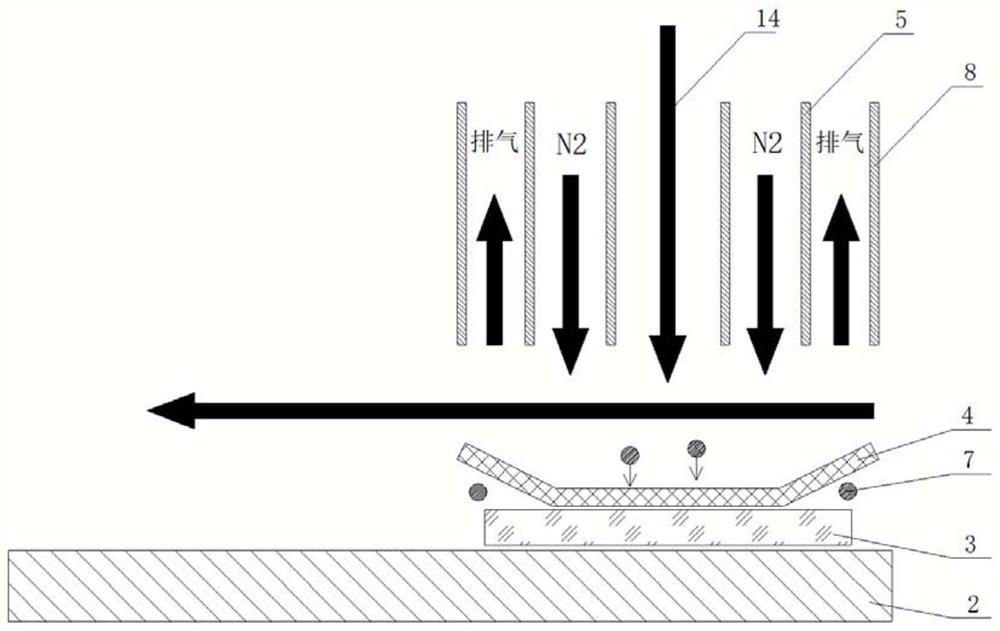

Thin film deposition device based on APCVD technology

PendingCN112593210AImprove protectionCorrection of curvatureChemical vapor deposition coatingWaferThin membrane

The invention discloses a thin film deposition device based on an APCVD technology, and relates to the technical field of normal-pressure chemical deposition. The thin film deposition device based onthe APCVD technology comprises a heating body assembly, a gas inlet box, a diffusion head, a vacuum system and an exhaust mechanism, wherein the heating body assembly is arranged above a wafer; the diffusion head is arranged below the wafer; the exhaust mechanism is arranged below the diffusion head; a gas outlet of the gas inlet box communicates with a gas inlet of the diffusion head; a large number of inert gas is not needed as a barrier, so that protective gas can be saved; through vacuum adsorption of the back surface of the wafer, bending of the wafer caused by film forming temperature and film stress is corrected, back surface film forming can be prevented, and film uniformity is improved; the film forming surface of the wafer faces downwards, and impurity particles fall down due togravity and then are taken away by airflow and do not fall on the wafer; the deposition range is large, thin film deposition is completed on the deposition surface at a time, and the uniformity of thethin film in the deposition surface is good; after the film is formed, the actual value of the film thickness uniformity is less than + / -2 percent; and the heating body assembly can drive the wafer to swing, so that the uniformity of the film on the deposition surface of the wafer can be further improved.

Owner:NINGBO HIPER VACUUM TECH CO LTD

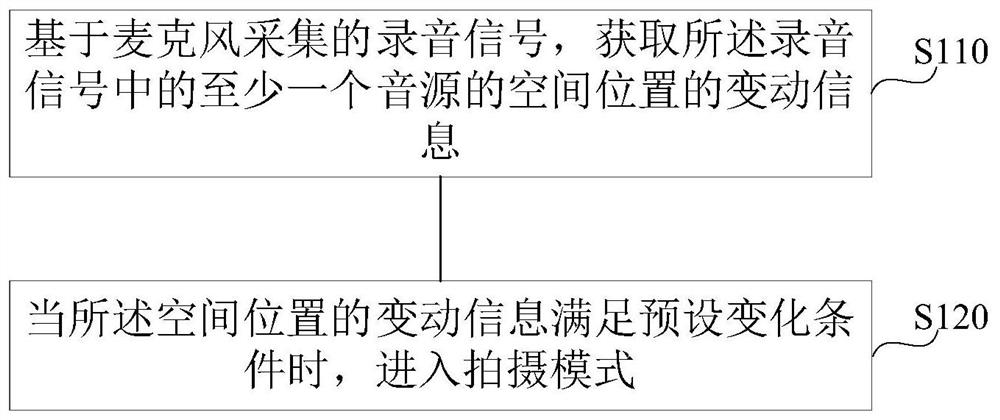

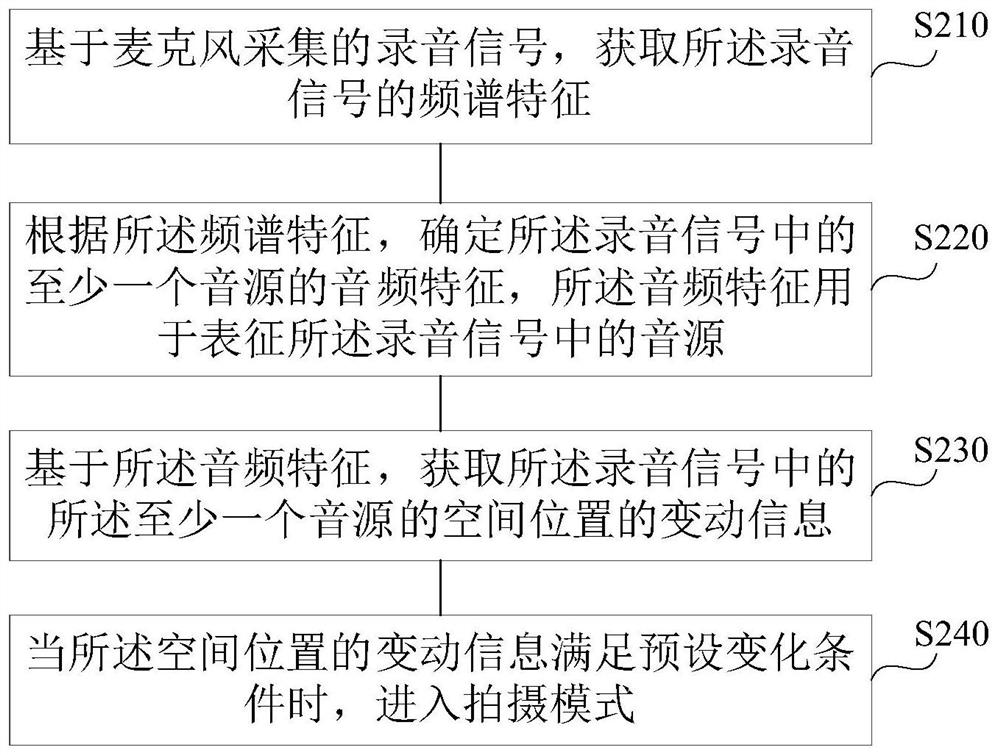

Shooting control method and device, electronic equipment and storage medium

ActiveCN113542606AReduce consumptionAchieving Adaptive ControlTelevision system detailsSpeech analysisSound sourcesEngineering

The invention discloses a shooting control method and device, electronic equipment and a storage medium, and is applied to the electronic equipment. The shooting control method comprises the following steps: based on a recording signal acquired by a microphone, acquiring change information of a spatial position of at least one sound source in the recording signal; and when the change information of the spatial position meets a preset change condition, activating a shooting mode. According to the method, the adaptive control of shooting is realized by tracking the spatial position change of the external sound, so that the shooting equipment is prevented from continuously shooting and recording, and the storage space is saved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

A cleaning method for metal nanowires

ActiveCN106862553BQuick washQuick cleaning processTransportation and packagingMetal-working apparatusInorganic saltsFiltration

The invention discloses a method for cleaning metal nanowires, which includes a coating process, a cleaning process, a dispersion process and a cleaning process, and is characterized in that the method for cleaning metal nanowires forms a protective layer on the surface of the metal nanowires. The protective layer effectively prevents the precipitation of metal nanowires during subsequent suction filtration and washing, and then removes solvents, organic polymers and inorganic salts by suction filtration and washing, and finally removes the protective layer on the surface of metal nanowires. The beneficial effect of the present invention is that all The rapid and efficient cleaning process of metal nanowires overcomes the shortcomings of long time-consuming centrifugal washing, cumbersome operation, and low efficiency. The fast and efficient cleaning effectively avoids the film-forming phenomenon during the filtration and washing process, and improves the yield and quality of the product.

Owner:山东利特纳米技术有限公司

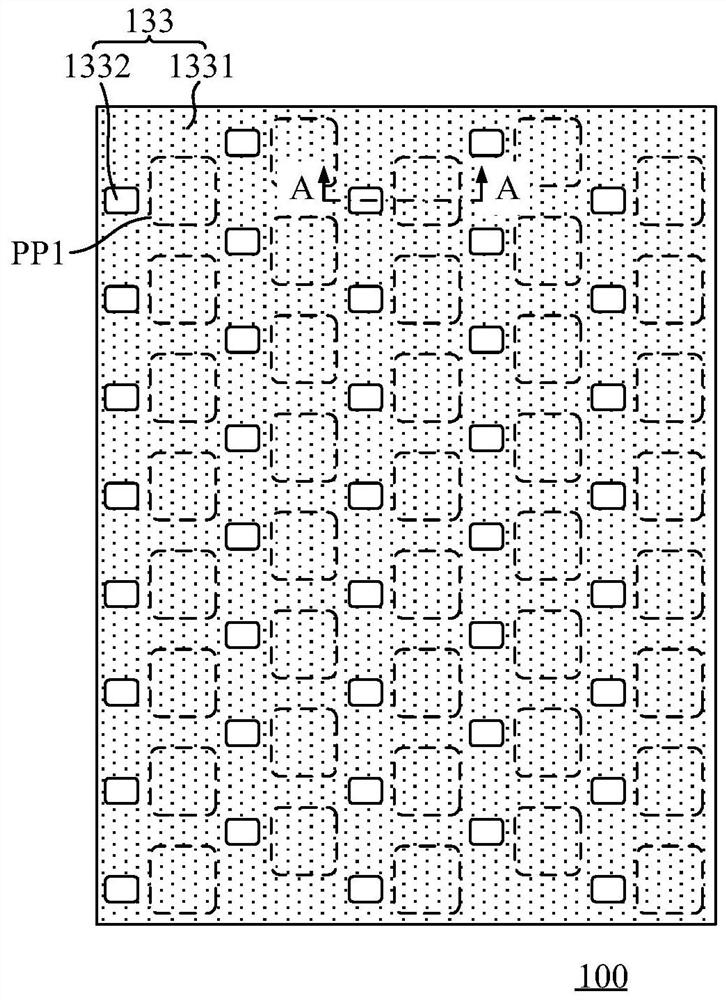

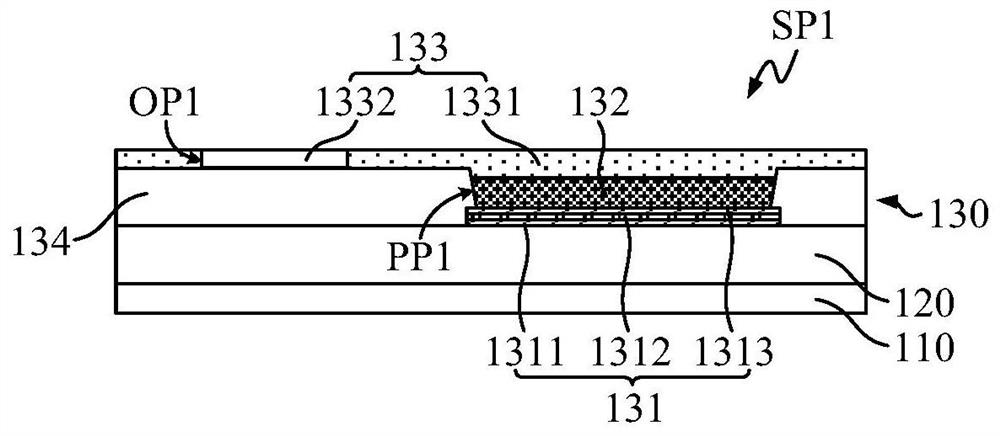

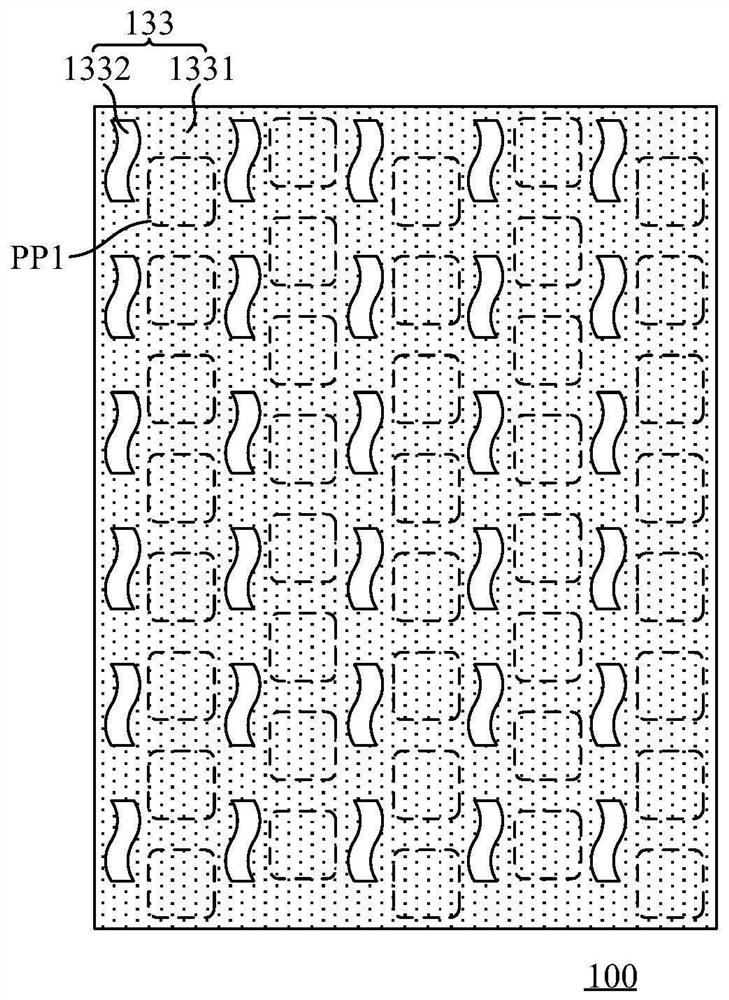

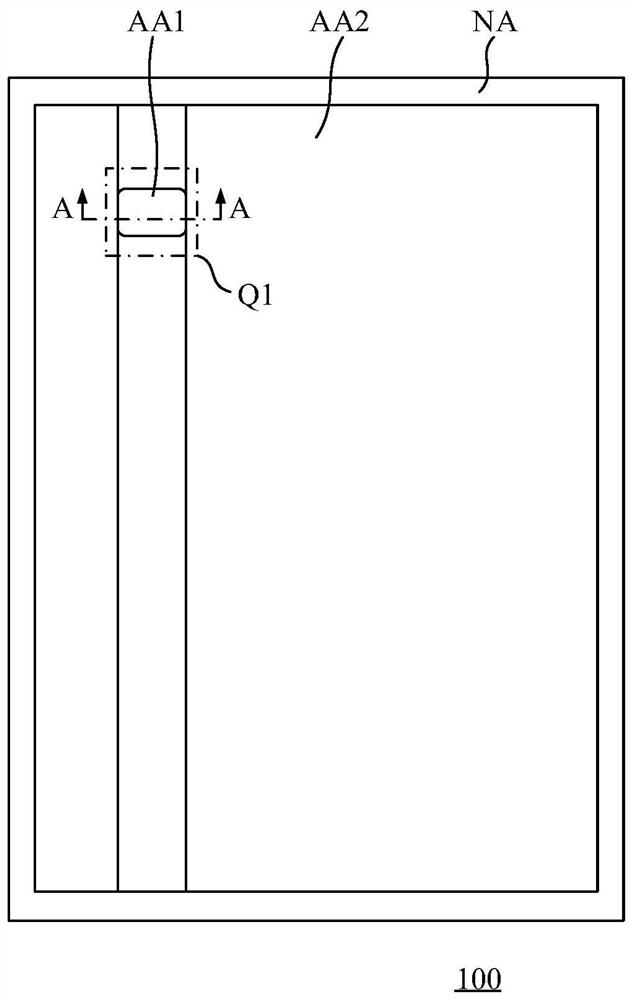

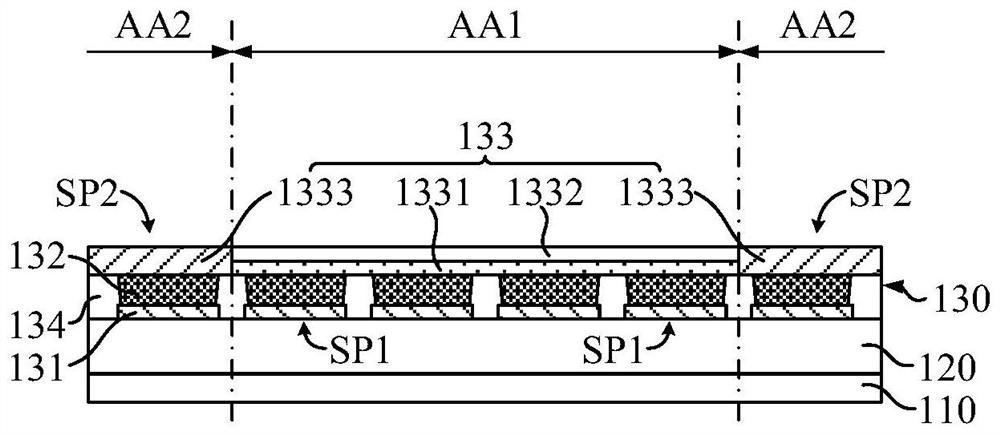

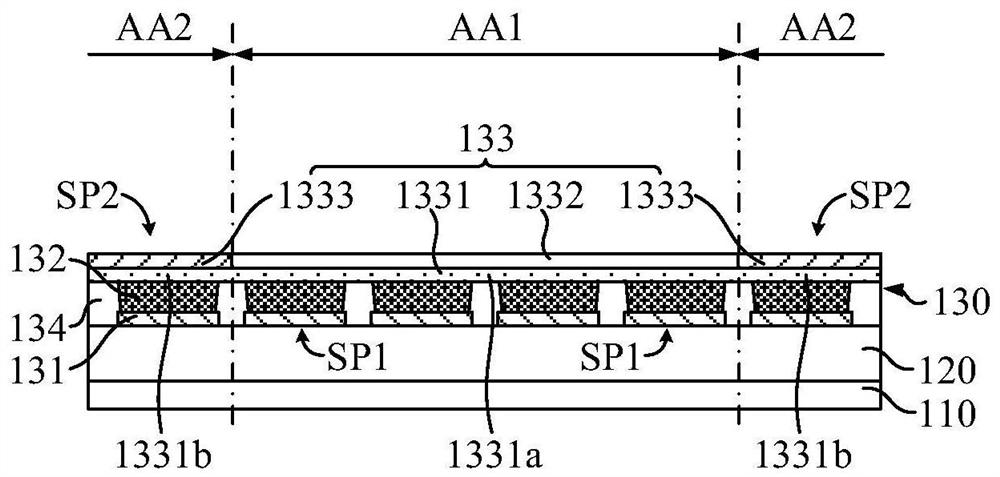

Light-transmitting display panel, display panel, manufacturing method, and display device

ActiveCN110783485BHigh light transmittanceAccurate patterningSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention discloses a light-transmitting display panel, a display panel, a manufacturing method and a display device. The light-transmitting display panel includes: a substrate; and a light-emitting element layer located on the substrate, the light-emitting element layer including a first electrode, a first light-emitting structure located on the first electrode, and a second electrode assembly located on the first light-emitting structure, Wherein, the second electrode assembly includes: a second electrode located on the first light-emitting structure, the second electrode has a plurality of openings; and a light-transmitting block located in the opening, and the material of the light-transmitting block is separated from the material of the second electrode. According to the light-transmitting display panel of the embodiment of the present invention, the repellency between the material of the light-transmitting block and the material of the second electrode is used to avoid film formation in the area with the light-transmitting block, so as to accurately realize the patterning of the second electrode.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

External additive, method of manufacturing same and toner

InactiveCN101424890BAvoid flyingPrevent background pollutionMaterial nanotechnologyPigmenting treatmentSilane compoundsSilanes

The invention provides a titanium dioxide external additive which is capable of being controlled stably, maintaining frictional charging amount, having less ambient variation, maintaining stable frictional charging performance, and which is free from abnormal images resulted from attachment of a toner to a photoreceptor that is generated while image developing and subjected to a surface modification treatment. The invention also provides an electrostatic charge images developing toner that is externally added with the external additive and an image forming method using the electrostatic charge images developing toner. The inventive external additive has the characteristic that particle surface of titanium dioxide having a water-soluble component of more than 0.2% is modified by the fluorosilane compound.

Owner:RICOH KK

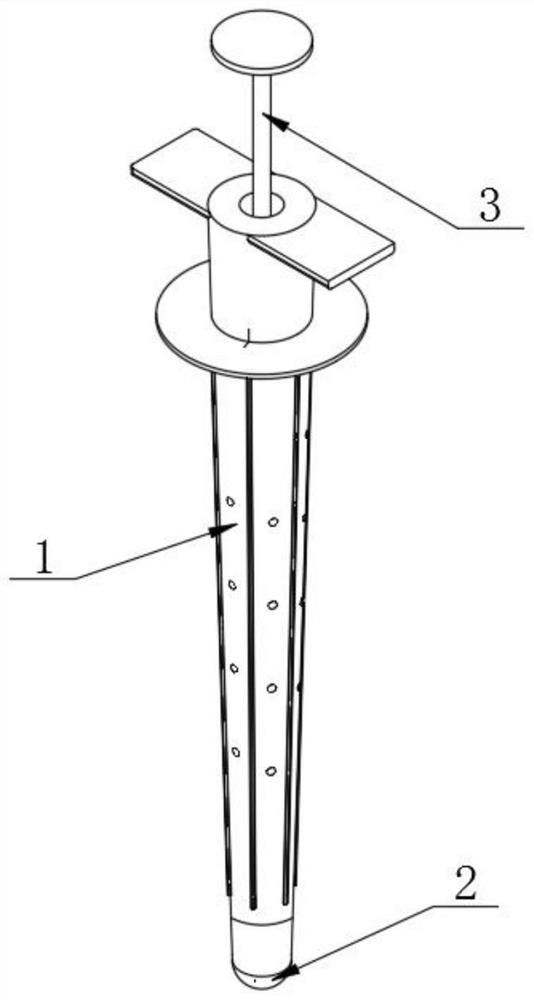

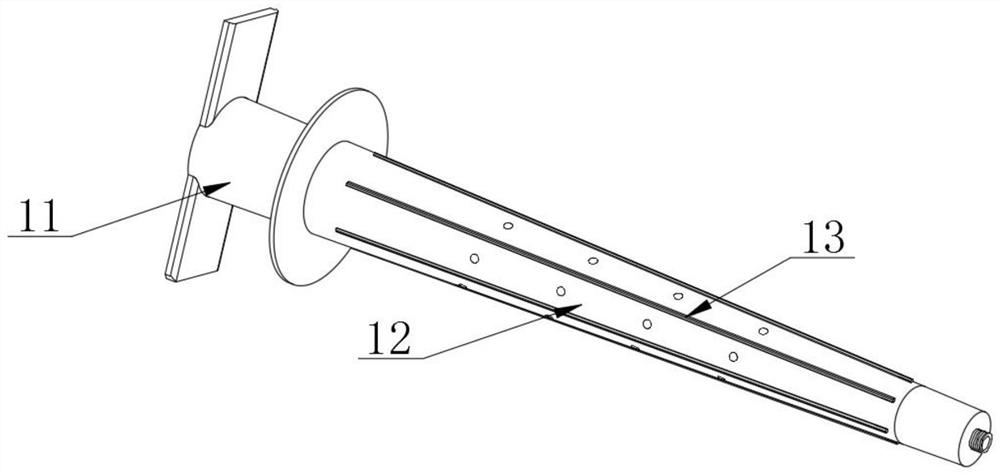

High-safety auditory meatus administration device for ear-nose-throat nursing

The invention discloses a high-safety auditory meatus administration device for ear-nose-throat nursing, and particularly relates to the field of medical instruments, the high-safety auditory meatus administration device comprises an administration tube, a protective end is detachably and movably arranged at the top end of the administration tube, a push rod is movably arranged in the administration tube, and the administration tube comprises a main tube. According to the drug delivery device, the drug delivery pipe and the protective end are used in cooperation, drugs in the material storage cavity are squeezed through the material pushing piston, the drugs are discharged out of the material storage cavity through the first material distribution holes and the second material distribution holes at different heights under the action of pressure change, the drugs are subjected to drug delivery operation in a tiny water drop shape, and the drug delivery efficiency is improved. The phenomenon that the medicine forms a film due to the fact that the medicine rapidly flows out of one opening when the medicine is administrated in a traditional mode is effectively avoided, so that it is guaranteed that the medicine is administrated to the affected part in place, the treatment effect is guaranteed, then the medicine administration pipe is rotated, the extruded medicine is evenly smeared through the protection cushion cover and the protection strip, and it is guaranteed that the good treatment effect can be obtained after external auditory canals are smeared with the medicine.

Owner:THE FIRST AFFILIATED HOSPITAL OF ZHENGZHOU UNIV

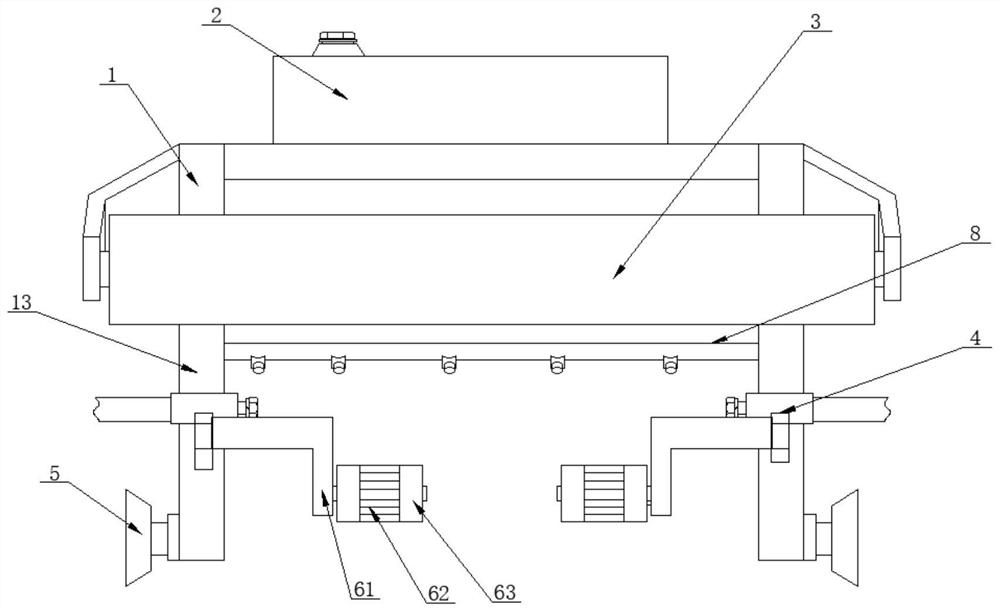

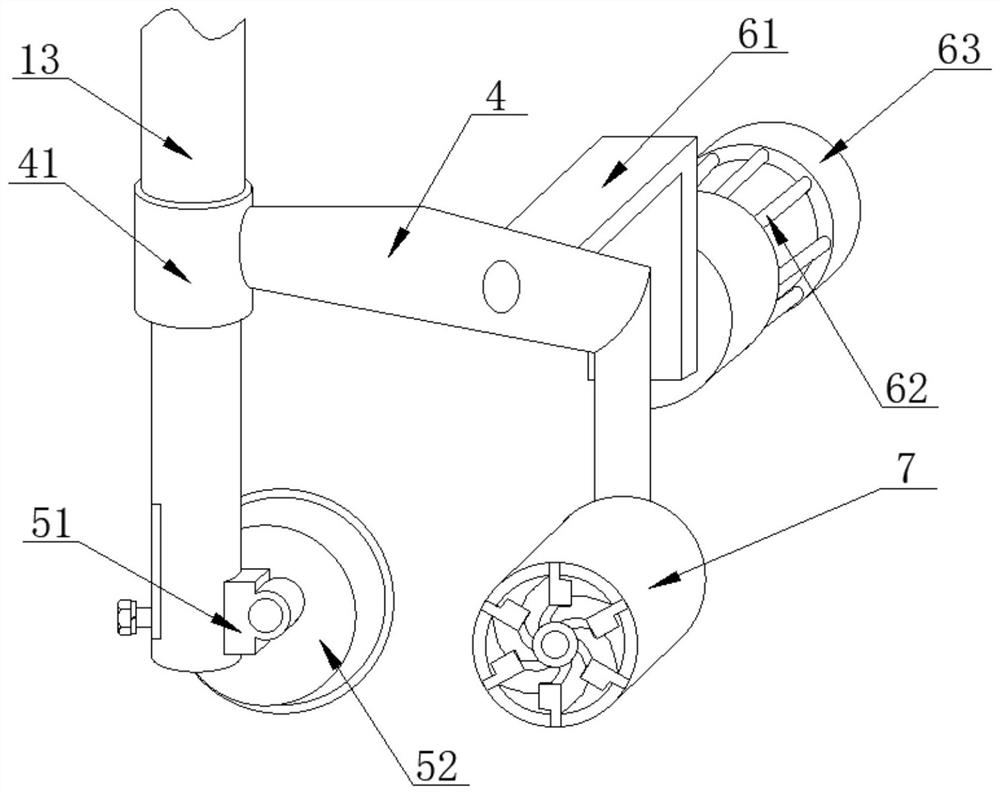

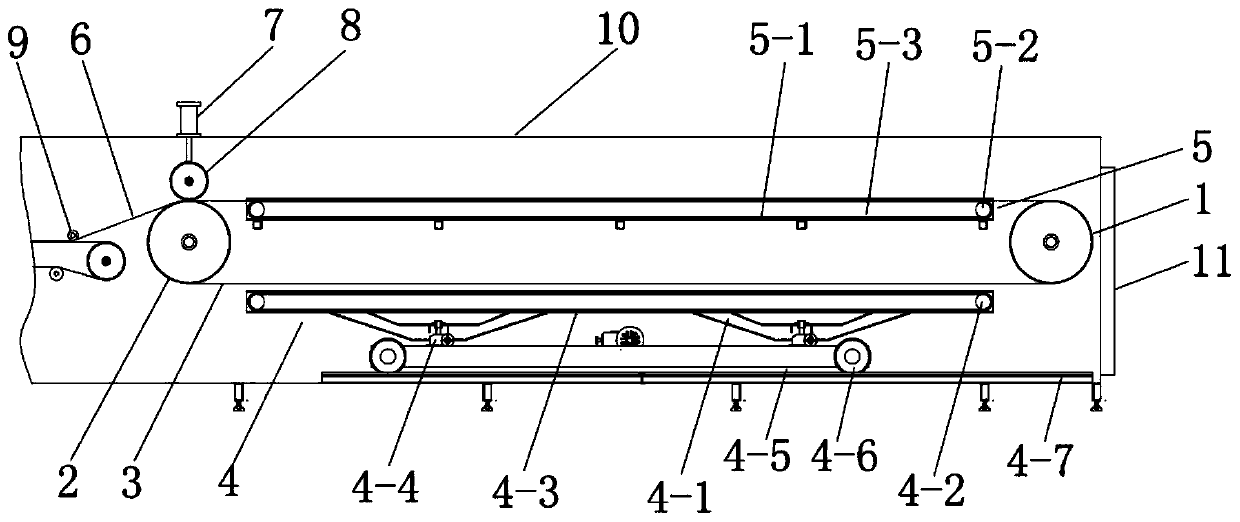

Laminating machine used for vacuum microwave drying furnace

The invention relates to a laminating machine used for a vacuum microwave drying furnace. The laminating machine comprises a belt wheel, a pressure bearing stick, a conveying belt, a following supporting vehicle, a belt supporting mechanism and a sheeting mechanism. The belt wheel and the pressure bearing stick are horizontally correspondingly arranged. The conveying belt is arranged on the belt wheel and the pressure bearing stick in a sleeving manner for conveying. The sheeting mechanism is matched with the pressure bearing stick so as to laminate rubber materials. The belt supporting mechanism is arranged at the bottom of an upper-layer conveying belt body, the following supporting vehicle is arranged below a lower-layer conveying belt body, and the material supporting height of the following supporting vehicle can be adjusted in an ascending and descending manner. By means of the laminating machine, the size of the laminating machine can be effectively reduced, the laminating machine can be suitable for vacuum microwave drying furnaces which are newly developed and used for rubber sheet production, the equipment manufacturing cost and maintenance difficulty are reduced, and reliable running is ensured.

Owner:江苏圣耐普特矿山设备制造有限公司

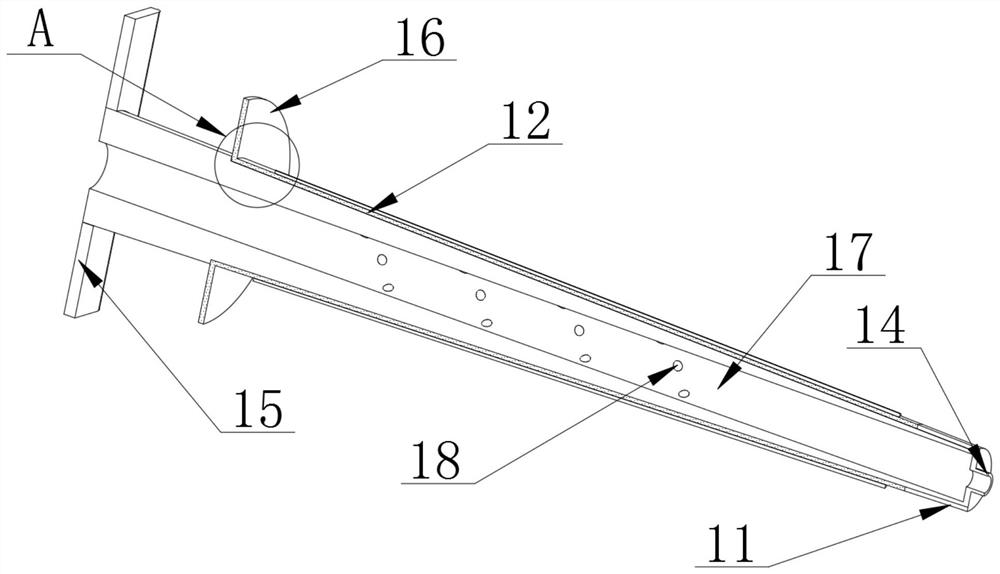

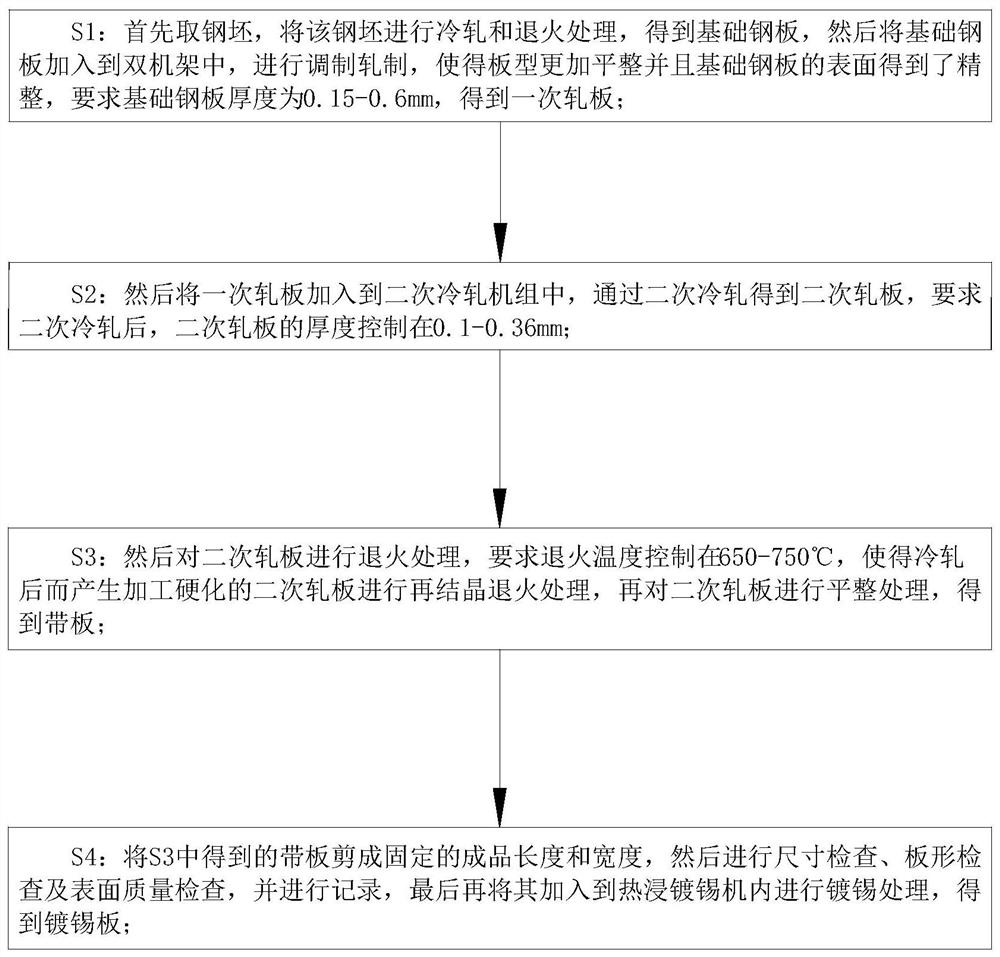

Double-reduced tin plate

PendingCN112376012ARealize automatic tin platingGuaranteed normal importHot-dipping/immersion processesMetallurgyTin plating

The invention belongs to the technical field of tin plate processing, and particularly relates to a double-reduced tin plate. A hot-dip tinning machine used in a production process of the tin plate comprises a shell, a tinning box and a sealing baffle plate, a placement plate is arranged at the position, close to the left side face of the shell, inside the shell, a cut strip plate is stacked on the upper surface of the placement plate, the tinning box is fixedly connected to the position, on the right side of the placement plate, inside the shell, and the sealing baffle plate is connected to the interior of the tinning box in a left-right sliding mode. By means of the machine, automatic tinning on the cut strip plate is effectively achieved, meanwhile, through a sealing structure, the tinning box is always isolated from outside air in a one-way mode while it is guaranteed that the cut strip plate is normally guided into the tinning box, so that liquid tin inside the tinning box is guaranteed not to make direct contact with air, the condition that the liquid tin liquid level is oxidized, so that the quality of the cut strip plate is influences is avoided, meanwhile, the problem thata large amount of tin gas generated by tin liquid evaporation is exhausted and pollutes the atmosphere is solved, and the tin plating quality is improved.

Owner:徐国进

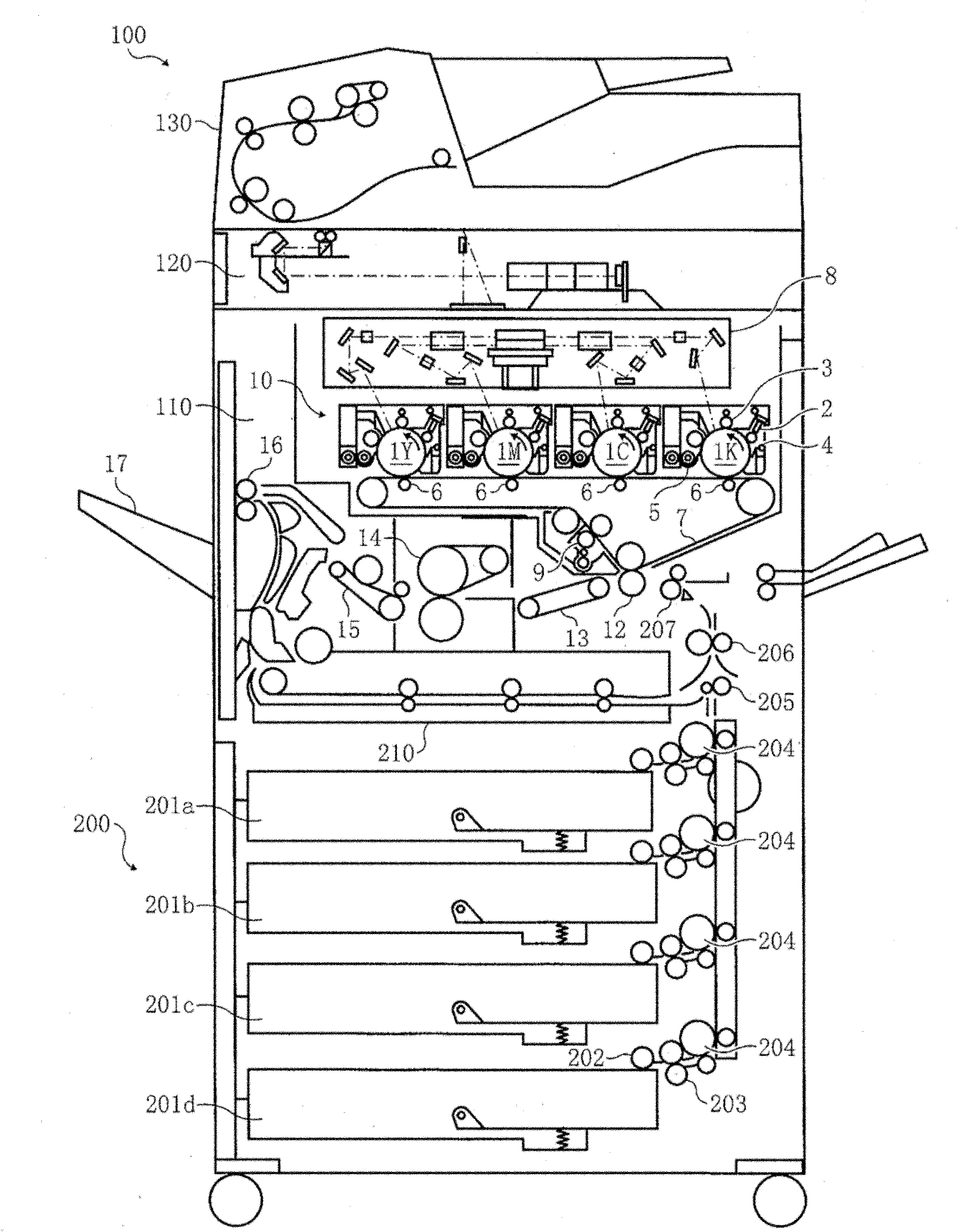

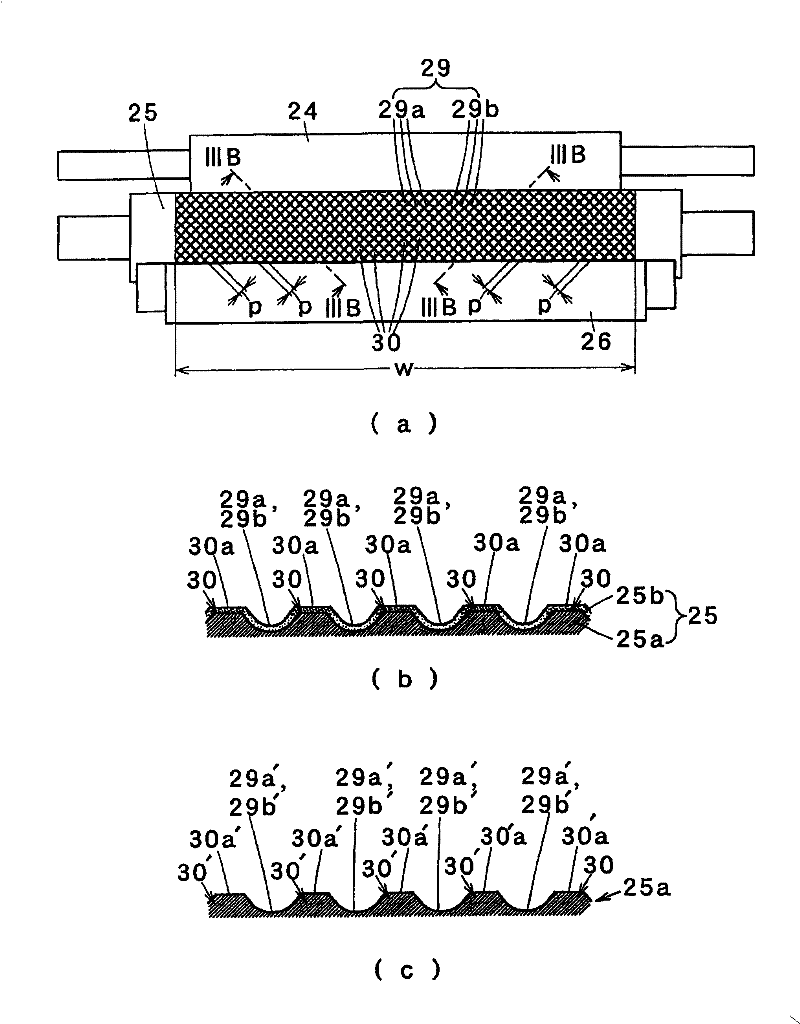

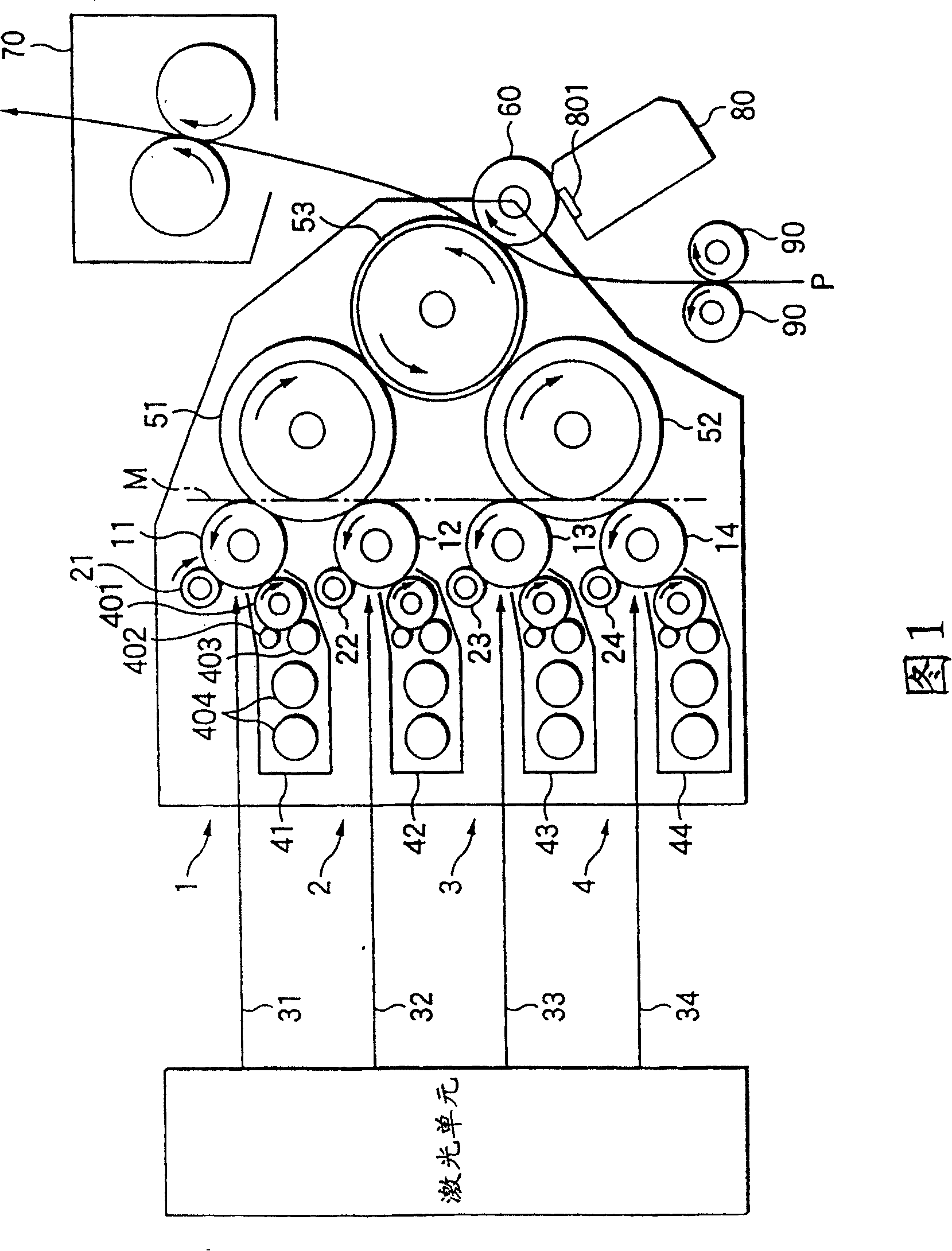

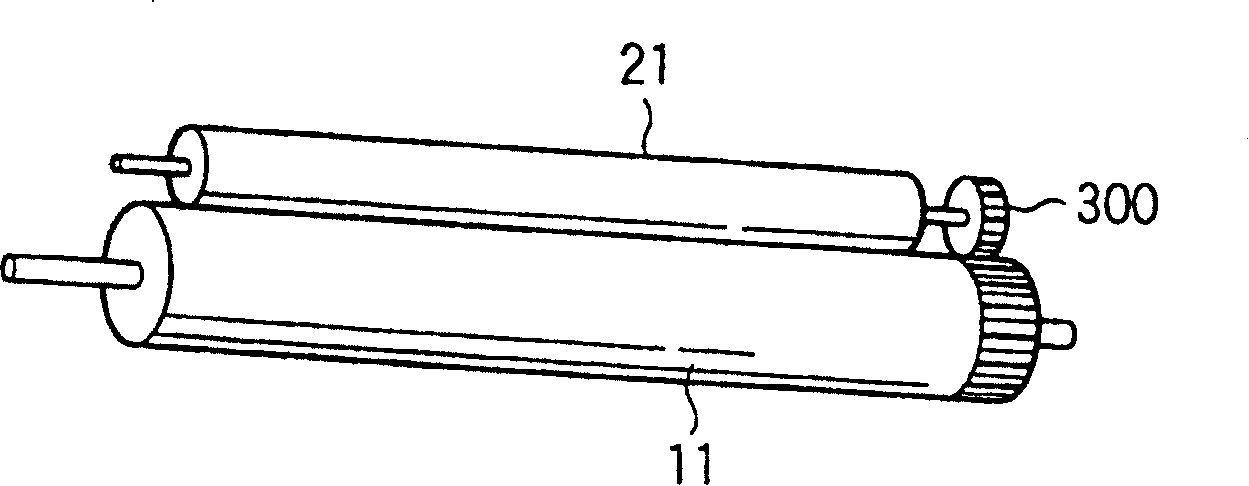

Development roller, development device, image forming apparatus, and method of manufacturing development roller

InactiveCN101515145BInhibit wearInhibition of changes in depthLiquid/solution decomposition chemical coatingElectrographic process apparatusSurface layerImage formation

Owner:SEIKO EPSON CORP

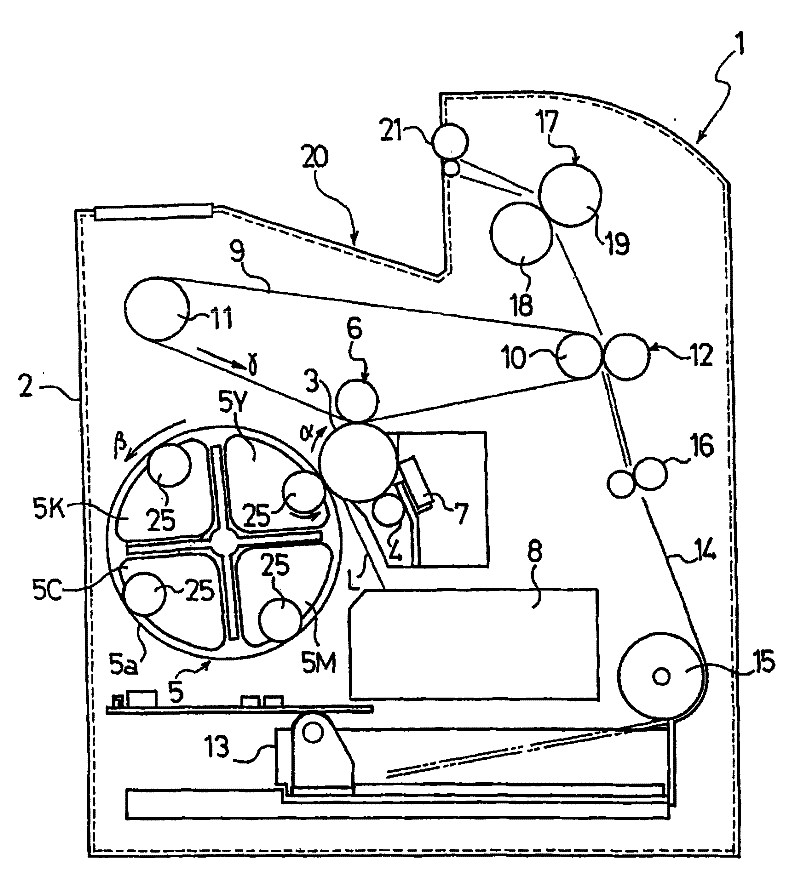

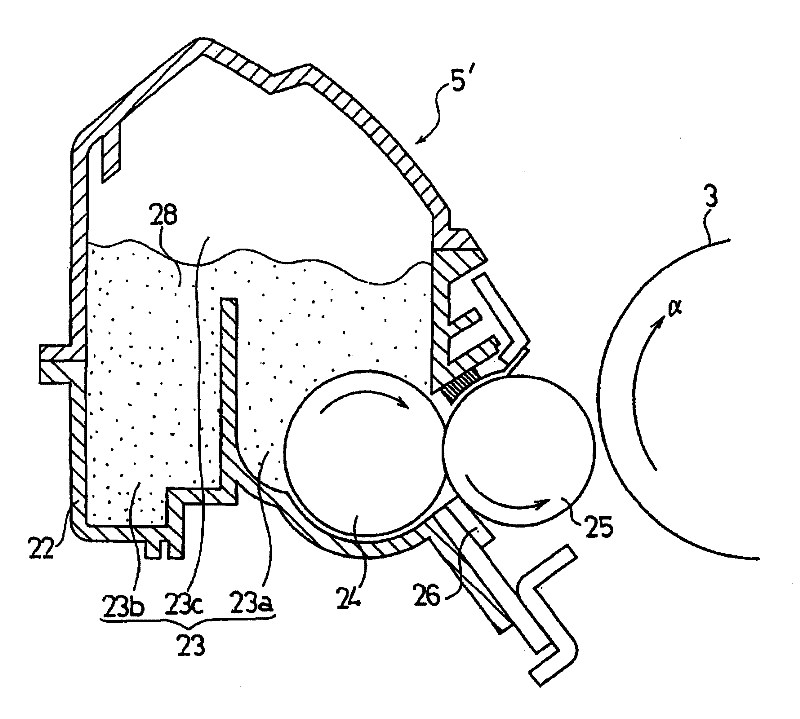

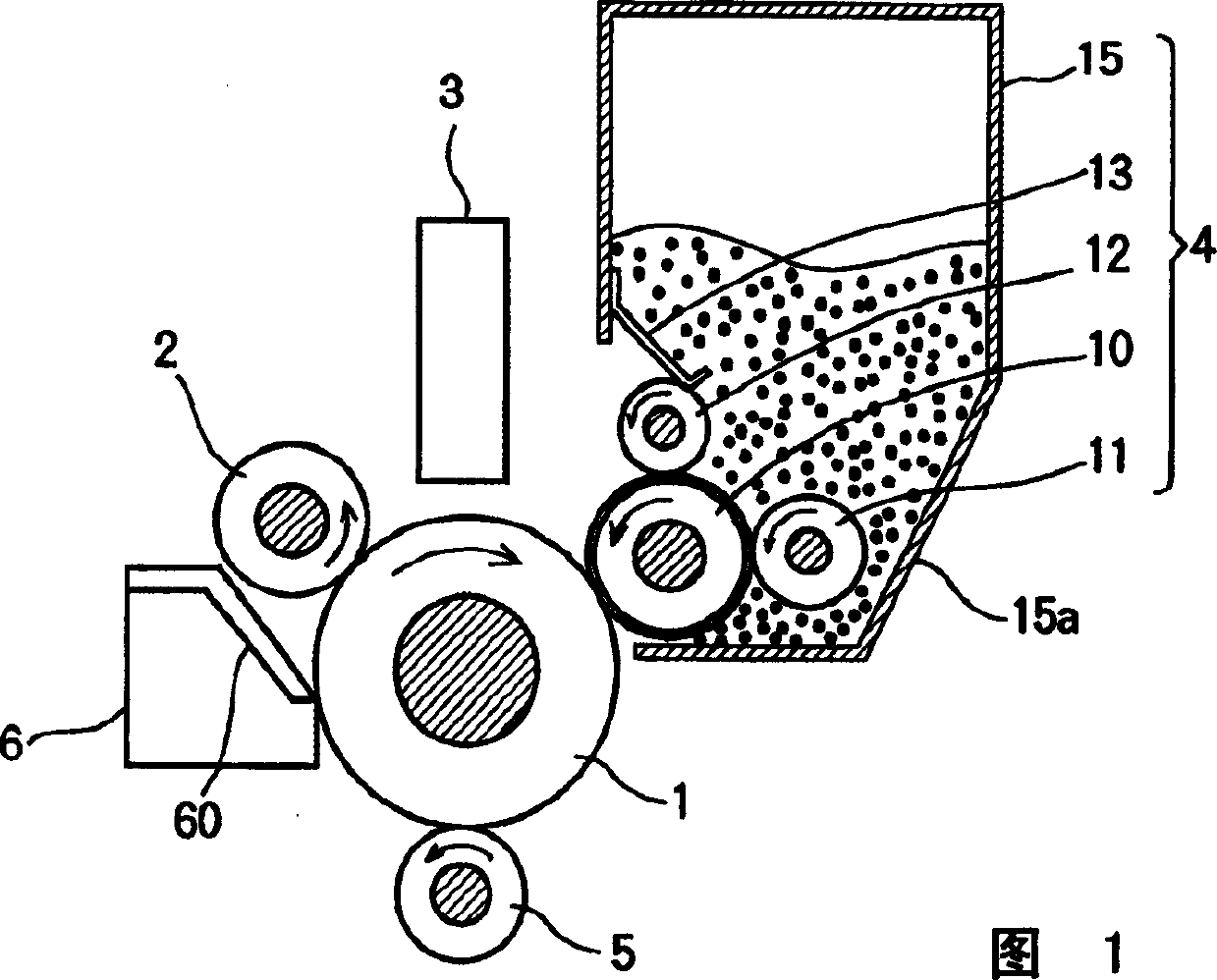

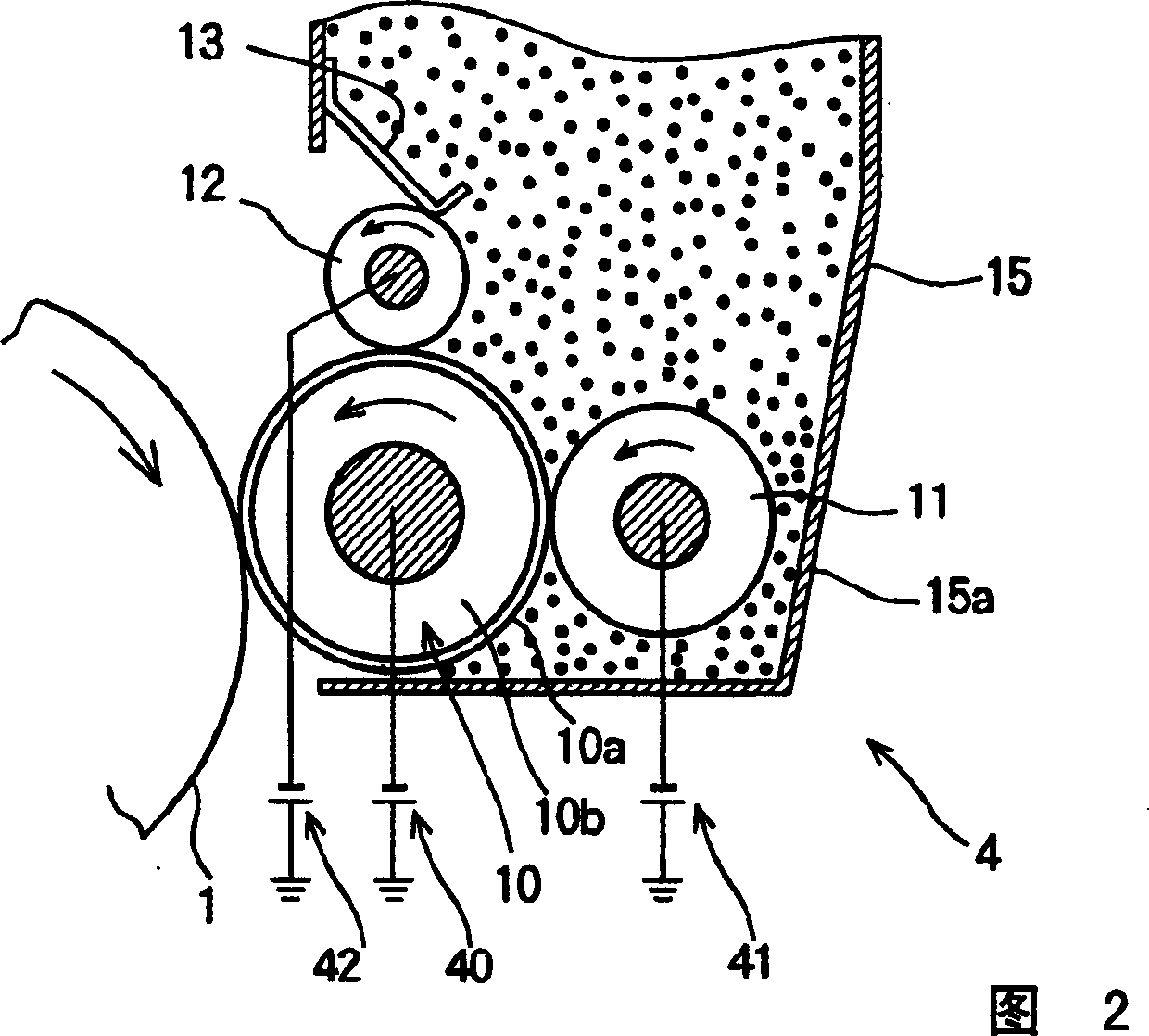

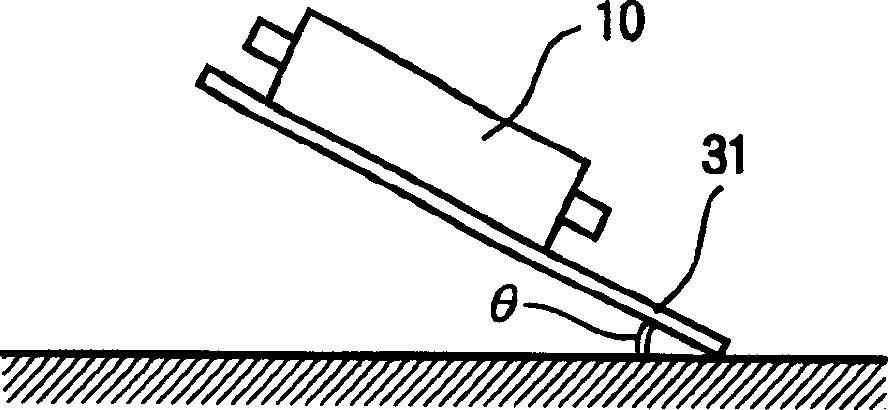

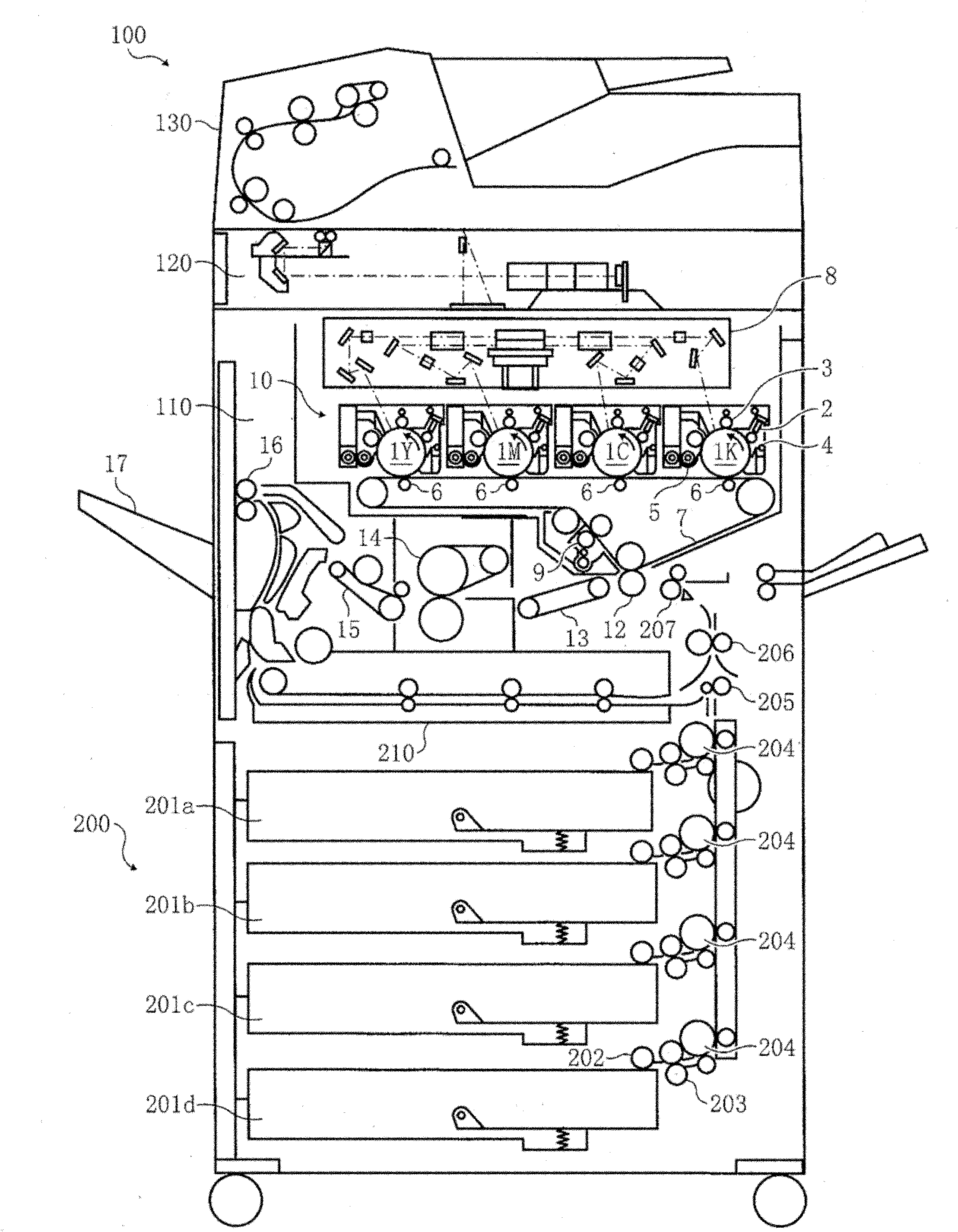

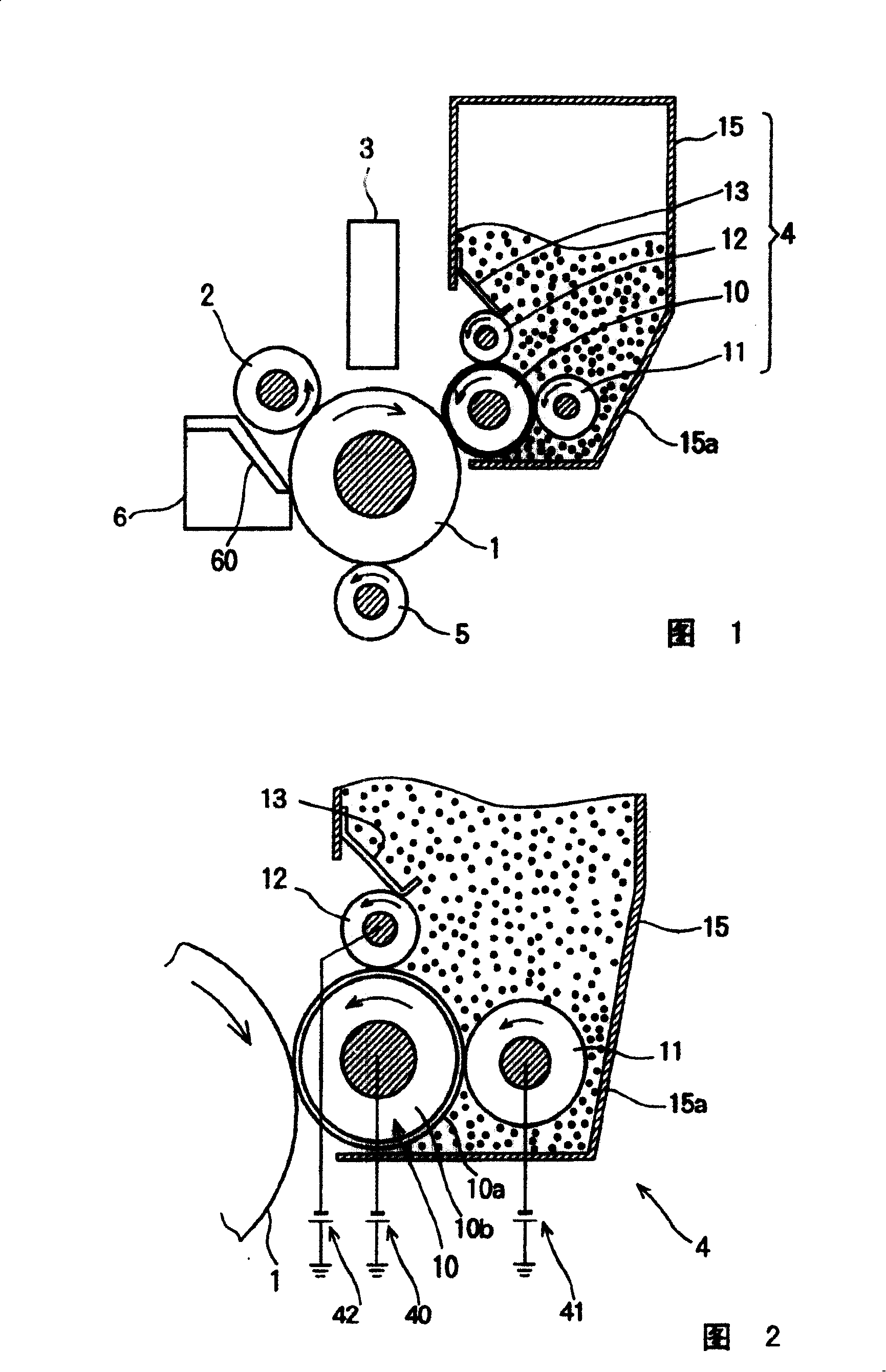

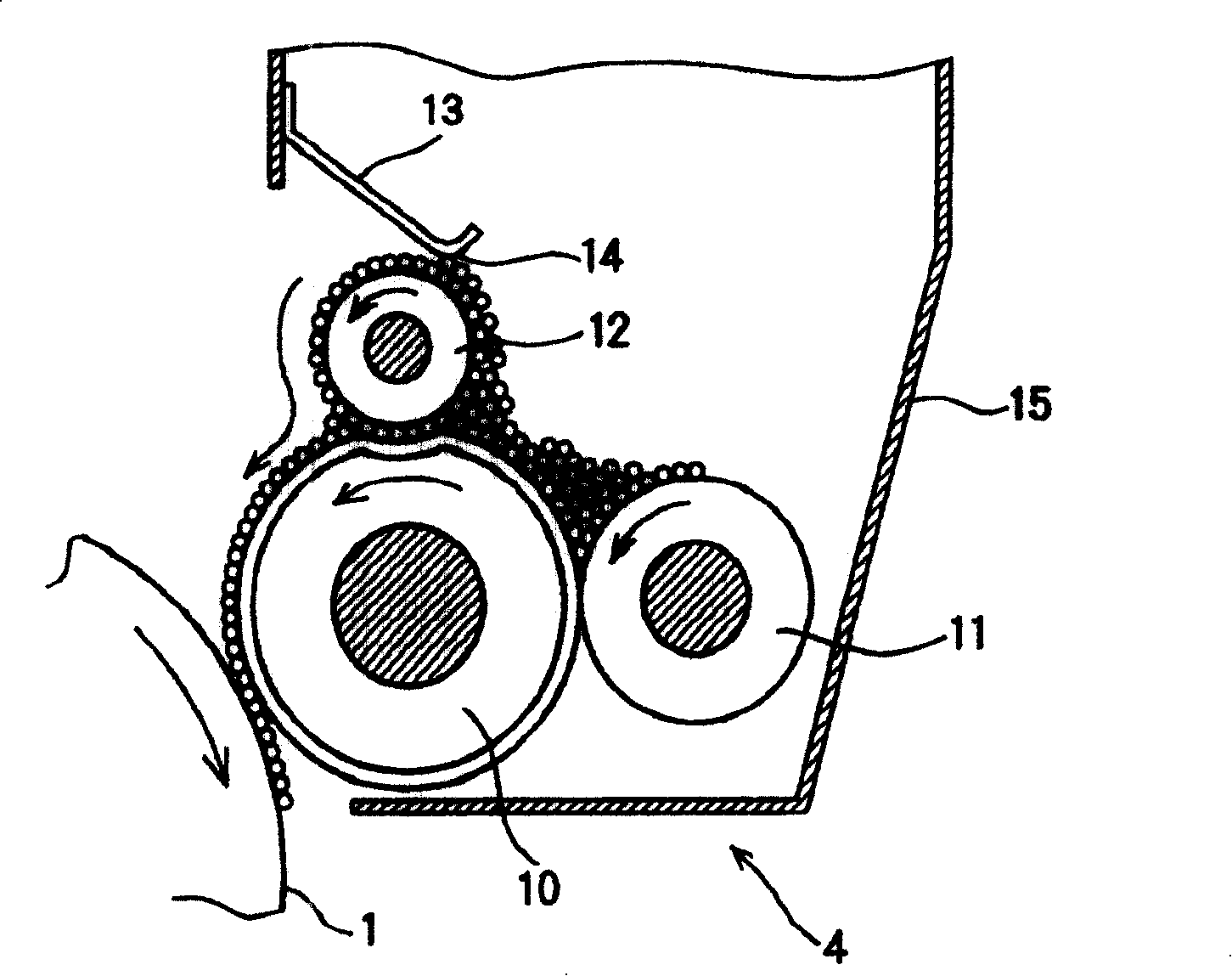

Development device and electronic photographing apparatus

InactiveCN1475873AChange concentrationPreventing Image Quality DeteriorationElectrographic process apparatusEngineeringMechanical engineering

A developing device (4) includes a developing roller (10) that faces a drum (1), a supplying roller (11) that supplies the toner to the developing roller (10), and a toner container (15) for storing the toner. A toner layer forming roller (12) contacts the developing roller (10) and rotates in the same direction as the developing roller (10). A part of the toner is transferred from the developing roller (10) to the peripheral surface of the toner layer forming roller (12) to form a toner layer. The thickness of the toner layer on the toner layer forming roller (12) is regulated by a blade (13). According to the rotation of the toner layer forming roller (12), the toner layer is carried outside the toner container (15), where the toner layer is transferred to the peripheral surface of the developing roller (10).

Owner:OKI DATA CORP

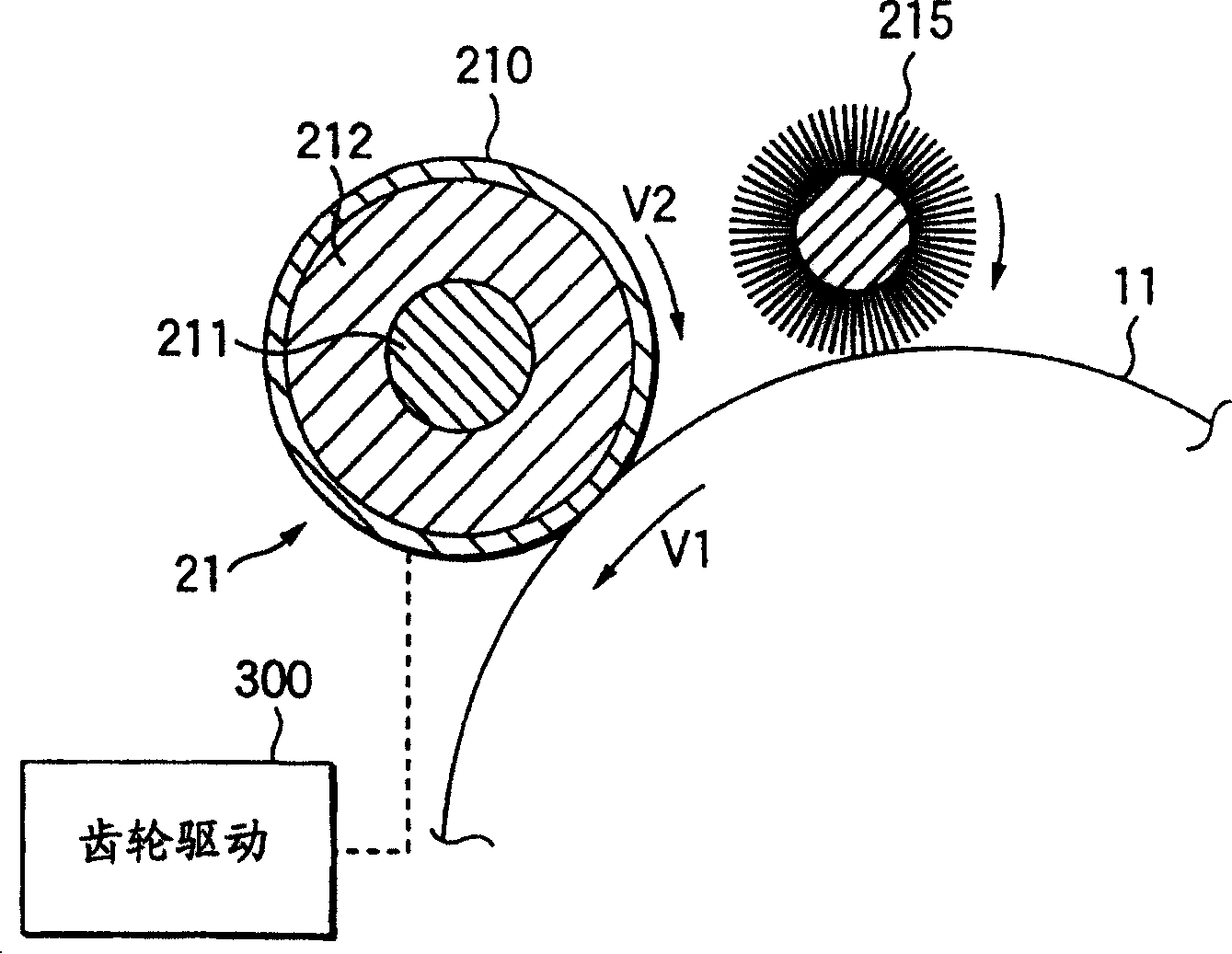

Charging device and imaging device using same

InactiveCN100392525CPrevent adhesionPrevent filmingElectrographic process apparatusCorona dischargeSurface roughnessEngineering

A charger has a cylindrical rotation tube coming in contact with an image receptor on which a toner image is formed, the rotation tube to which a predetermined charge bias is applied, and drive means for driving the rotation tube at a predetermined peripheral speed, the charger for uniformly charging the surface of the image receptor. When the peripheral speed of the image receptor is V1 and the peripheral speed of the rotation tube is V2, the following relation is satisfied: 1.01<(V2 / V1)<=1.10.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Protective agent feeding member, protective layer forming apparatus, and image forming apparatus

Owner:RICOH KK

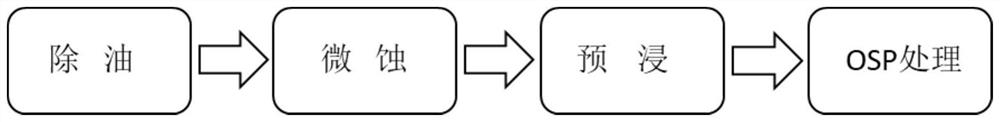

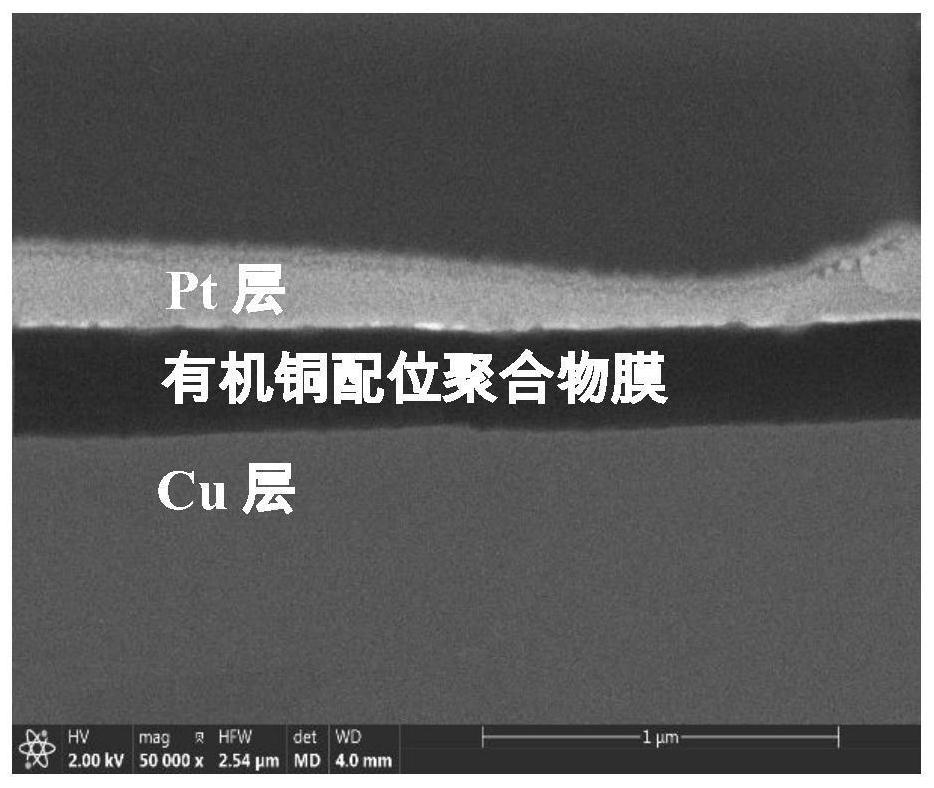

A kind of preparation method of organic solderability protective agent and organic copper coordination polymer film

ActiveCN111360450BImprove heat resistanceReduce pollutionWelding/cutting media/materialsSoldering mediaPhysical chemistrySolderability

The invention relates to an organic solderability protective agent, wherein an imidazole compound is selected as the main film-forming substance of the organic solderability protective agent, which improves the heat resistance of the organic copper coordination polymer film of a printed circuit board formed subsequently, It can meet the temperature required for lead-free soldering and reduce environmental pollution. After multiple reflow soldering treatments, the performance of the organic copper coordination polymer film is still very stable, which meets the needs of the PCB surface treatment production process. OSP solution As far as it is concerned, it is very stable, and the film formed on the surface of the PCB can effectively prevent copper from being oxidized for a certain period of time. At the same time, it maintains good solderability under lead-free reflow temperature soldering, and has excellent copper and gold options. sex. The printed circuit organic solderability protectant provided by the invention conforms to the progress and development of integrated circuit technology. In addition, the invention also relates to a method for preparing an organic copper coordination polymer film.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Image-bearing member protecting agent and image forming method

ActiveCN102129205BFully protectedPrevent filmingElectrographic process apparatusLubricant compositionImage formationStructural engineering

Owner:RICOH KK

Film forming method and sputtering device

ActiveCN106715750BPrevent filmingElectric discharge tubesVacuum evaporation coatingSputteringHigh frequency power

The present invention relates to a film formation method and a sputtering apparatus which suppress the formation of an inhomogeneous film at the start and end of film formation without providing a target moving mechanism. This sputtering apparatus generates inductively coupled plasma (22) by supplying high-frequency power (PR) to an antenna (20) installed in a vacuum vessel (2) into which gas (10) is introduced, and utilizing the plasma ( 22) With the target bias voltage (VT), the target (30) is sputtered to form a film on the substrate (12). At the start of film formation, high-frequency power (PR) is supplied to the antenna (20) to generate plasma (22), and then a target bias voltage (VT) is applied to the target (30) to start sputtering. At the end of the film, after the target bias voltage (VT) applied to the target (30) is stopped to stop sputtering, the high-frequency power (PR) supplied to the antenna (20) is stopped and the plasma (22) disappears .

Owner:NISSIN ELECTRIC CO LTD

Display panel, manufacturing method thereof, and display device

ActiveCN110783484BIncrease the display areaHigh light transmittanceSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention discloses a display panel, a manufacturing method thereof, and a display device. The display panel has a first display area and a second display area, the light transmittance of the first display area is greater than the light transmittance of the second display area, the display panel includes: a substrate; and a light emitting element layer, including a first electrode, located at the second A light-emitting structure on an electrode and a second electrode assembly located on the light-emitting structure, wherein the second electrode assembly includes: a light-transmitting electrode, at least partially located in the first display area; a light-transmitting block, located in the first display area, disposed on the transparent on the photoelectrode; and the second electrode, located in the second display area, and the material of the second electrode is separated from the material of the light-transmitting electrode. According to the display panel of the embodiment of the present invention, the material of the second electrode is repellent to the material of the light-transmitting block, which prevents the second electrode from forming a film in the region with the light-transmitting block, thereby accurately realizing the patterning of the second electrode , to prevent the second electrode from being formed in the first display area from affecting the light transmittance of the first display area.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

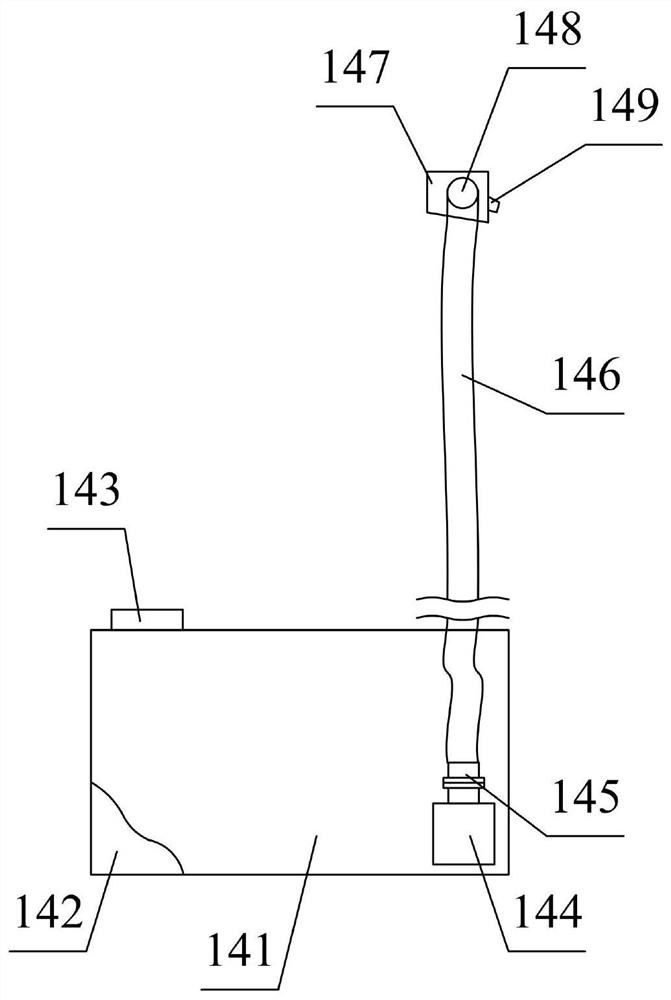

Intelligent CSP system

ActiveCN111749861BEasy to move aroundPrevent filmingFrom solar energyMachines/enginesMolten saltIndustrial engineering

The invention provides an intelligent photothermal power generation system, including a box, a support frame, a base plate, a first concentrating plate, a second concentrating plate, a socket tube, a telescopic rod, a clamping block, a molten salt tube, a casing, a PLC, a drive switch, The rod frame structure can be cleaned, the auxiliary flushing seat structure can support the rotating shell frame structure and the auxiliary measurement box frame structure, the support frames are respectively bolted to the left and right ends of the box body; and the upper end of the box body; the first concentrating plate and the second concentrating plate are respectively bolted on the left and right sides of the upper end of the base plate; the sleeve pipes are respectively welded on the middle part of the front and rear parts of the upper end of the box body. The beneficial effects of the present invention are: through the arrangement of the cleanable rod frame structure, when the cleaning pad moves left and right, the sundries on the surface of the first condensing plate and the second condensing plate can be cleaned accordingly, thereby avoiding the first concentrating plate and the second concentrating plate. Debris on the surface of the second concentrator shadows the effect of electricity.

Owner:SHANDONG YAOGUO NEW ENERGY TECH

A kind of preparation method of nano cellulose fiber dry powder

The invention relates to a preparation method of nano-cellulose fiber dry powder, which comprises the following steps: 1) taking cellulose, pulverizing and drying to obtain cellulose raw material, which is ready for use; 2) mixing organic acid and alcohol to obtain a reaction liquid, and reacting The mass fraction of organic acid in the liquid is 20-30%. The reaction liquid is heated to 140-160° C., the cellulose raw material obtained in step 1) is added, kept warm and stirred; 3) After the cellulose raw material is fully destroyed and dispersed, the reaction system Carry out solid-liquid separation treatment to obtain reaction recovery liquid and solid powder, and after the solid powder is washed with alcohol, disperse into alcohol to obtain a solid powder dispersion; 4) Homogenize the solid powder dispersion obtained in step 3), Obtaining the nanocellulose fiber dispersion; 5) Evaporating to dryness the alcohol in the nanocellulose fiber dispersion in step 4) to obtain the nanocellulose fiber dry powder.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

Development device and electronic photographing apparatus

InactiveCN100388129CChange concentrationPreventing Image Quality DeteriorationElectrographic process apparatusEngineeringElectrical and Electronics engineering

A developing device (4) includes a developing roller (10) that faces a drum (1), a supplying roller (11) that supplies the toner to the developing roller (10), and a toner container (15) for storing the toner. A toner layer forming roller (12) contacts the developing roller (10) and rotates in the same direction as the developing roller (10). A part of the toner is transferred from the developing roller (10) to the peripheral surface of the toner layer forming roller (12) to form a toner layer. The thickness of the toner layer on the toner layer forming roller (12) is regulated by a blade (13). According to the rotation of the toner layer forming roller (12), the toner layer is carried outside the toner container (15), where the toner layer is transferred to the peripheral surface of the developing roller (10).

Owner:OKI DATA CORP

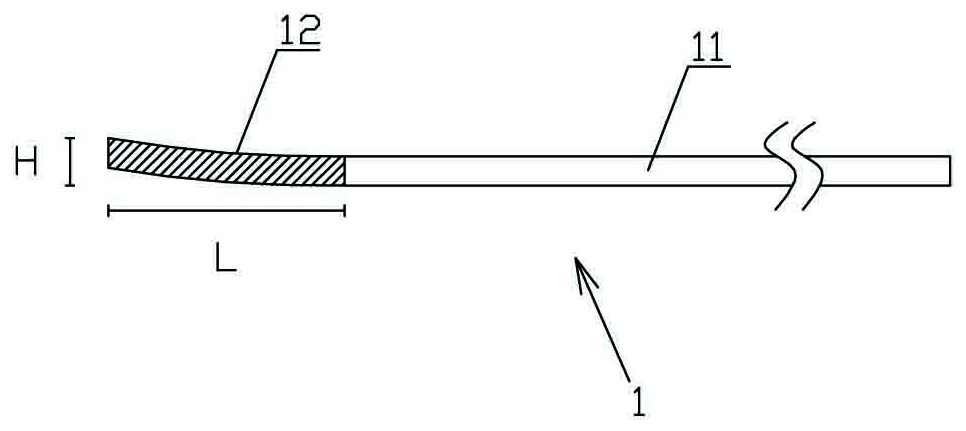

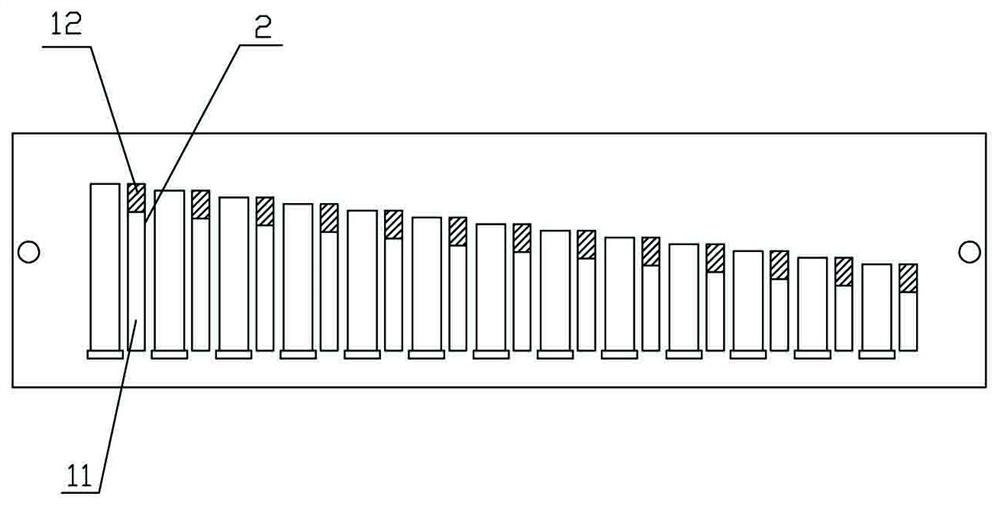

Diaphragm of anti-sticking film/anti-flapping film of chromatic harmonica

PendingCN112767899ASolve mucous membrane problemsLow adhesionWind musical instrumentsEngineeringAir tightness

The invention discloses a diaphragm of an anti-sticking film / anti-flapping film of a chromatic harmonica. The diaphragm comprises a diaphragm body, the diaphragm body is composed of a tiled section and an arc-shaped section, the tiled section is parallel to the horizontal plane, the front end of the arc-shaped section is connected with the tail end of the tiled section, and the arc-shaped section is gradually and naturally bent upwards in an arc shape from front to back; and the height of the arc-shaped section is 1.3-1.8 mm, the length of the arc-shaped section is 10-12 mm, the height of the arc-shaped section is equal to the distance between the highest point position of the tail end of the arc-shaped section and the horizontal plane position of the front end of the arc-shaped section, and the length of the arc-shaped section is equal to the distance between the front end and the tail end of the arc-shaped section. According to the invention, the diaphragm can be attached to a spring plate, the air tightness of the spring plate can be ensured, the contact position at the tail end of the spring plate cannot be influenced by condensed water to generate the adhesion problem, on the other hand, the flatness of the tail section of the diaphragm can be more uniform and stable, and the generation of diaphragm beating can be effectively prevented.

Owner:吴鸿彬

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com