Double-reduced tin plate

A technology of secondary cold rolling and tinplate, applied in hot dip plating, coating, metal material coating, etc., can solve the problems of increasing labor cost, affecting the quality of tinplate, and low quality of tinplate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

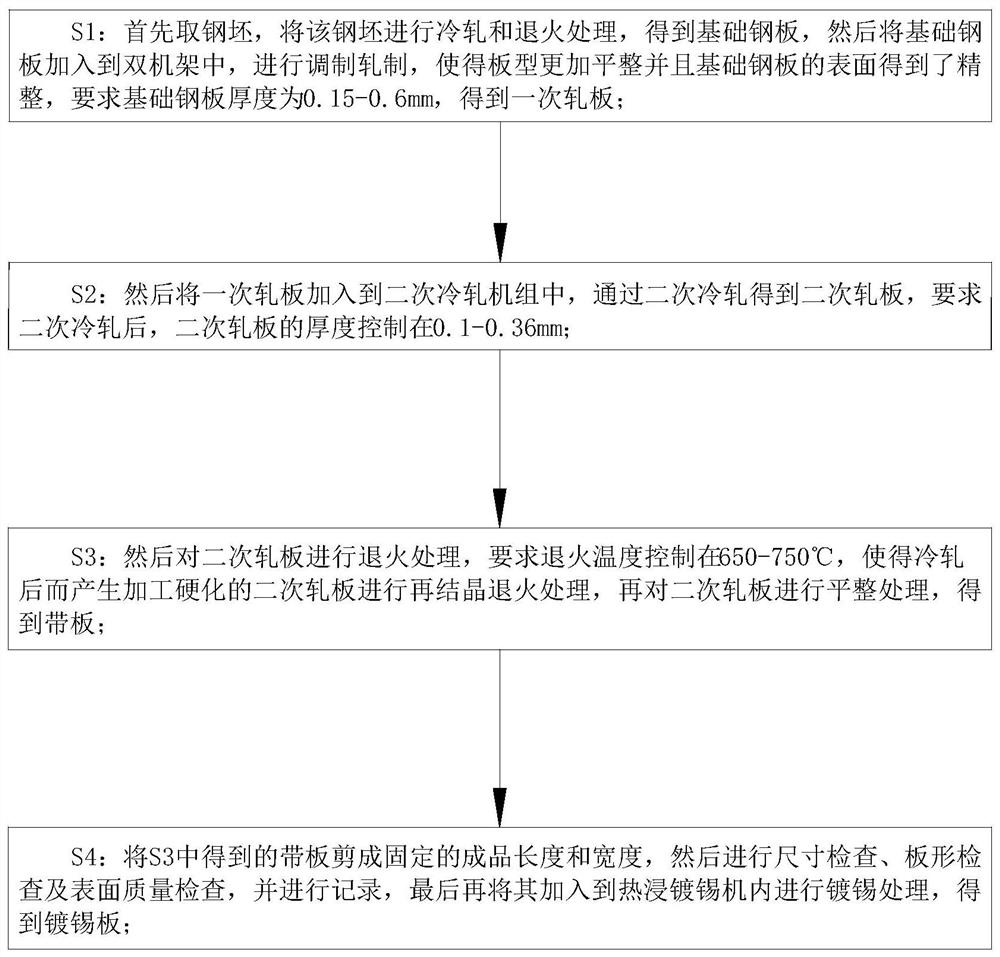

[0038] Such as Figure 1 to Figure 6 Shown, a kind of secondary cold-rolled tinplate of the present invention, the preparation method of this tinplate comprises the following steps:

[0039] S1: First take the billet, cold-roll and anneal the billet to obtain the basic steel plate, then add the basic steel plate into the double stand, and carry out modulation rolling, so that the plate shape is more flat and the surface of the basic steel plate is finished , the thickness of the basic steel plate is required to be 0.15-0.6mm, and a rolling plate is obtained;

[0040] S2: Then add the primary rolling plate to the secondary cold rolling unit, and obtain the secondary rolling plate through secondary cold rolling. After the secondary cold rolling, the thickness of the secondary rolling plate should be controlled at 0.1-0.36mm;

[0041] S3: Then perform annealing treatment on the secondary rolling plate, and the annealing temperature is required to be controlled at 650-750°C, so t...

Embodiment approach

[0047] As an embodiment of the present invention, the upper surface of the sealing baffle 3 is provided with a top groove; the inside of the top groove is slidably connected with a top plate 13; the groove bottom of the top groove is fixedly connected with a third telescopic rod 14 , and the upper end surface of the piston rod of the third telescopic rod 14 is fixedly connected with the top plate 13; during work, by setting the third telescopic rod 14, the top board 13 will be driven to move upward by the third telescopic rod 14, when the cut strip plate 6 approaches When sealing the baffle 3, in order to prevent the sliding of the sealing baffle 3 left and right on the lower surface of the cut-off strip 6, there is a gap between the sealing baffle 3 and the cut-off strip 6, and it can be ejected upwards through the top plate 13. The air in the gap space is completely squeezed out, avoiding that when the cutting baffle plate 6 continues to move downward, a small amount of air w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com