A cleaning method for metal nanowires

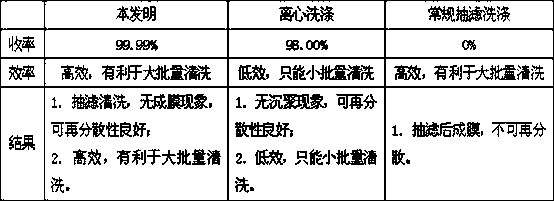

A metal nanowire and protective layer technology, applied in the field of nanomaterials, can solve the problems of low efficiency, cumbersome operation, long time consumption, etc., and achieve the effect of overcoming long time consumption, efficient cleaning, and avoiding film formation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Metal nanowire slurry 5mg / ml 100ml is mixed with 100ml of absolute ethanol, and 50mg of tetrabutyl titanate is added. After mixing, 250mg of deionized water is added, and a protective layer of titanium dioxide is formed on the surface of the metal nanowire.

[0028] 2. Wash the metal nanowires containing the titanium dioxide protective layer by suction filtration, wash the filter cake with deionized water to obtain the cleaned product; redisperse the cleaned product in 100 ml of 0.1 mg / ml polyvinylpyrrolidone aqueous solution, and mix well.

[0029] 3. Add 0.5 g of NaOH to the mixed solution obtained in the above step 2, mix evenly, leave it to stand and pour off the supernatant to obtain the washed metal nanowires.

Embodiment example 2

[0031] 1. Mix 5mg / ml 100ml of metal nanowire slurry with 100ml of isopropanol, add 50mg of tetrabutyl titanate, mix well and add 250mg of deionized water to form a silicon dioxide protective layer on the surface of the metal nanowire.

[0032] 2. Wash the metal nanowires containing the silicon dioxide protective layer by suction filtration, wash the filter cake with deionized water to obtain the cleaned product; redisperse the cleaned product in 100 ml of 0.1 mg / ml polyvinylpyrrolidone aqueous solution, and mix well.

[0033] 3. Add 0.5 g of NaOH to the mixed solution obtained in the above step 2, mix evenly, leave it to stand and pour off the supernatant to obtain the washed metal nanowires.

Embodiment example 3

[0035] 1. Mix 5mg / ml 100ml of metal nanowire slurry with 100ml deionized water, add 50mg of magnesium nitrate, mix well and add 250mg of sodium hydroxide to form a protective layer of magnesium hydroxide on the surface of the metal nanowire.

[0036] 2. Wash the metal nanowires containing the protective layer of magnesium hydroxide by suction filtration, wash the filter cake with deionized water to obtain the cleaned product; redisperse the cleaned product in 100 ml of 0.1 mg / ml polyvinylpyrrolidone aqueous solution, and mix well.

[0037] 3. Add 0.5 g of hydrochloric acid to the mixed solution obtained in the above step 2, after mixing evenly, leave it to stand and pour off the supernatant to obtain the washed metal nanowires.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com