Toner for developing electrostatic image, method for producing the same, developer, image forming apparatus, process cartridge, and image forming method

A technology for developing electrostatic images and toners, which is applied in the field of developers and toners for developing electrostatic latent images, and can solve problems such as film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

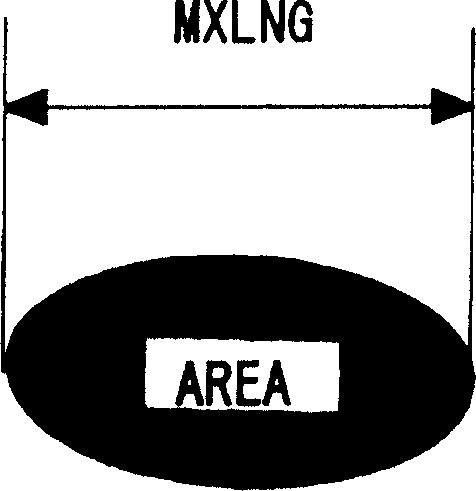

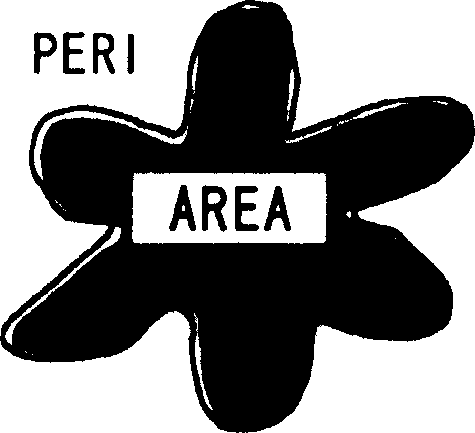

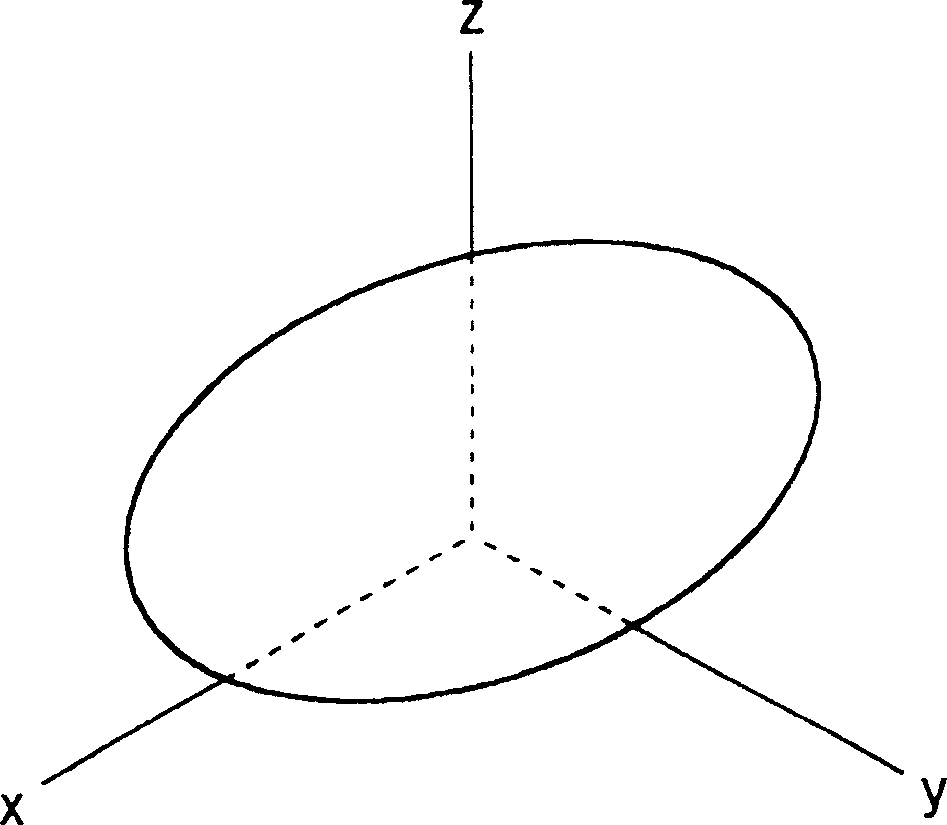

Image

Examples

Embodiment A

[0410] Next, the present invention will be further described through Example A, however, the present invention is not limited to this example. Parts represent parts by weight.

[0411] (Two-component developer evaluation)

[0412] When image evaluation is performed using a two-component developer, as shown below, a ferrite carrier with an average particle size of 35 μm coated with a silicone resin with an average thickness of 0.5 μm is used, and the form of stirring by rotating the container is used. A twist mixer uniformly mixed 7 parts by weight of toners of each color with respect to 100 parts by weight and charged them to prepare a developer.

[0413] (manufacture of carrier)

[0414] ·Core

[0415] Mn ferrite fine particles (weight average particle diameter: 35 μm) 5000 parts by weight

[0416] ·Coating material

[0417] 450 parts by weight of toluene

[0418] Silicone resin SR2400 (manufactured by Toray Douko-ning Silicone Co., Ltd. (Silicon), 50% non-volatile cont...

Embodiment A-1

[0431] ~Synthesis of Organic Microparticle Emulsion~

manufacture example 1

[0433] In a reaction vessel equipped with a stirrer and a thermometer, add 683 parts of water, 11 parts of sodium salt of methacrylic acid ethylene oxide adduct sulfate (Elemino-lu RS-30, manufactured by Sanyo Chemical Industry Co., Ltd.), 166 parts Methacrylic acid, 110 parts of butyl acrylate, and 1 part of ammonium persulfate were stirred at 3800 rpm for 30 minutes to obtain a white emulsion. The internal temperature of the system was raised to 75° C. by heating and reacted for 3 hours. Furthermore, 30 parts of 1% ammonium persulfate aqueous solution was added and aged at 70°C for 5 hours to obtain vinyl resin (sodium salt of methacrylic acid-butyl acrylate-methacrylic acid oxirane adduct sulfuric acid ester) A water-soluble dispersion ("microparticle dispersion 1"). The volume average particle diameter of "fine particle dispersion 1" measured using LA-920 was 75 nm. Part of the "fine particle dispersion 1" was dried to separate the resin component. The Tg of this resin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average particle size | aaaaa | aaaaa |

| Number average particle size | aaaaa | aaaaa |

| Primary particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com