Intelligent CSP system

A technology of photothermal power generation and concentrating plate, applied in the field of intelligent photothermal power generation system, can solve the problems of no cleaning function, inconvenient adjustment of the device, etc., and achieve the effect of increasing the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

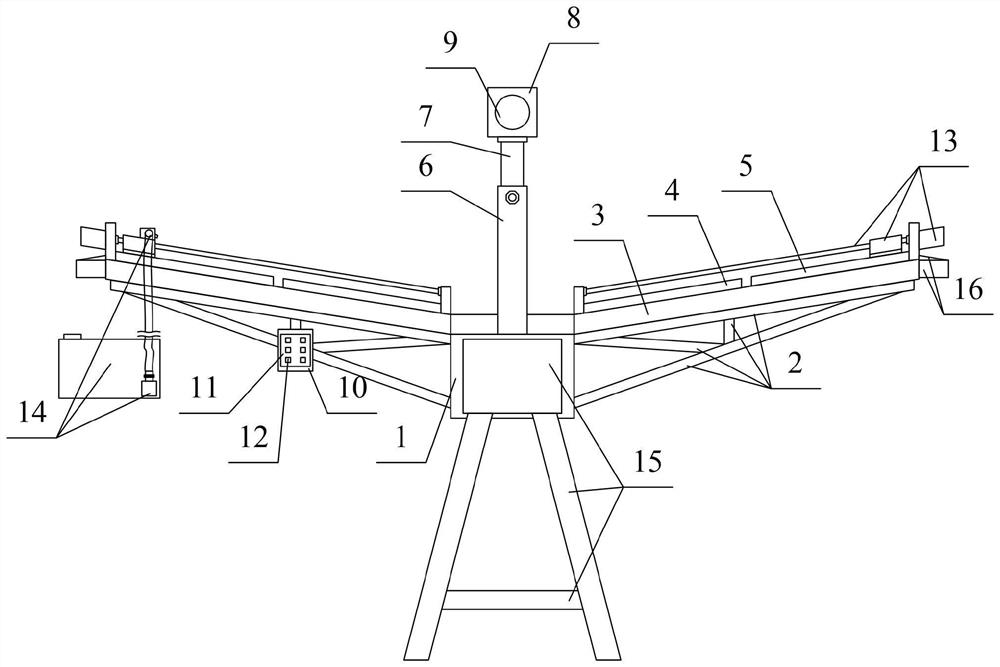

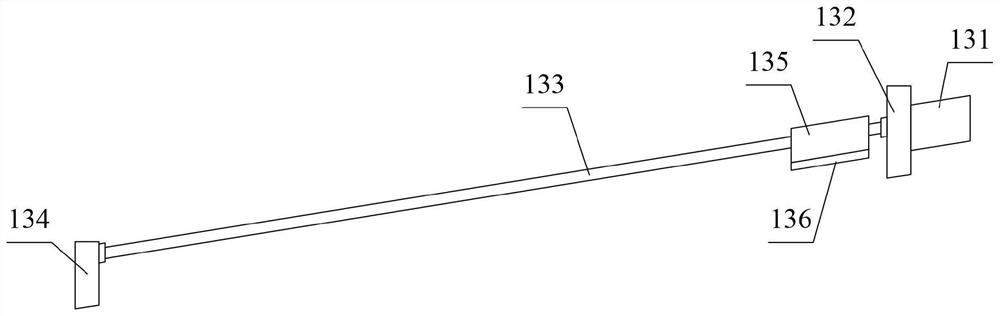

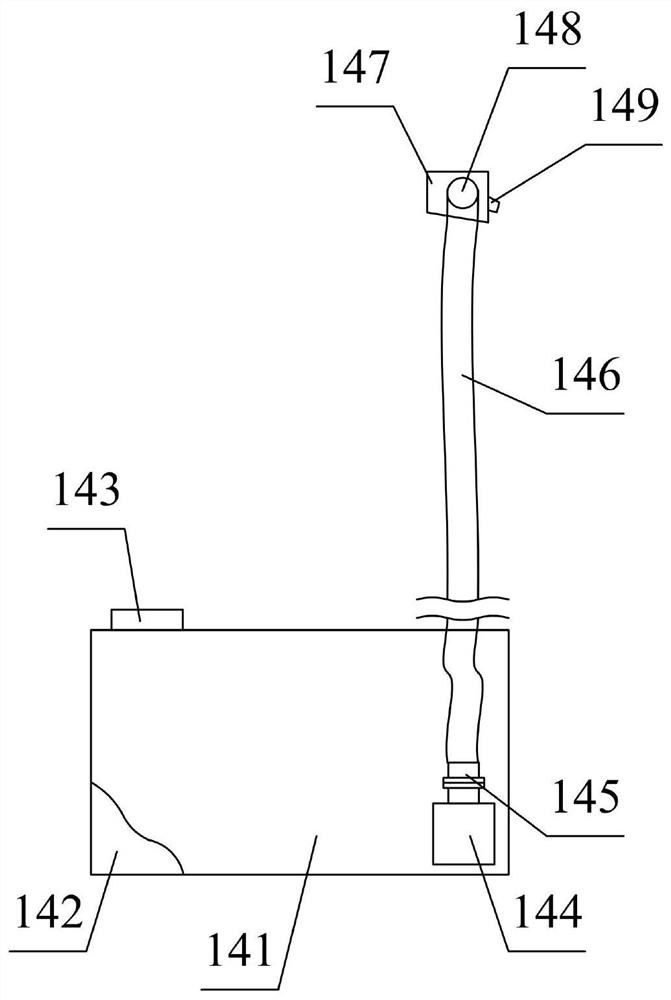

[0038] as attached figure 1 to the attached figure 2As shown, the intelligent CSP system includes a box 1, a support frame 2, a base plate 3, a first concentrating plate 4, a second concentrating plate 5, a sleeve pipe 6, a telescopic rod 7, a clamping block 8, and a molten salt pipe 9. Shell 10, PLC11, drive switch 12, washable rod frame structure 13, auxiliary flushing seat structure 14, supportable rotating frame structure 15 and auxiliary measurement box frame structure 16, the support frame 2 is bolted to the box respectively. The left and right ends of the body 1; the base plate 3 is respectively bolted to the upper end of the support frame 2 and the box body 1; The described sleeve pipe 6 is respectively welded on the middle part of the front and rear parts of the upper end of the box body 1; The molten salt tube 9 is embedded between the clamping blocks 8; the casing 10 is bolted to the front surface of the support frame 2 at the left end of the box 1; the PLC11 bol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com