External additive, method of manufacturing same and toner

An electrostatic charge image and external additive technology, applied in the direction of developer, electric recording process using charge pattern, electric recording process using charge pattern, etc., can solve problems such as inability to obtain quality, carrier particle adhesion, surface treatment layer damage, etc. , to achieve the effects of improving durability, improving electrification, and preventing scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example -A

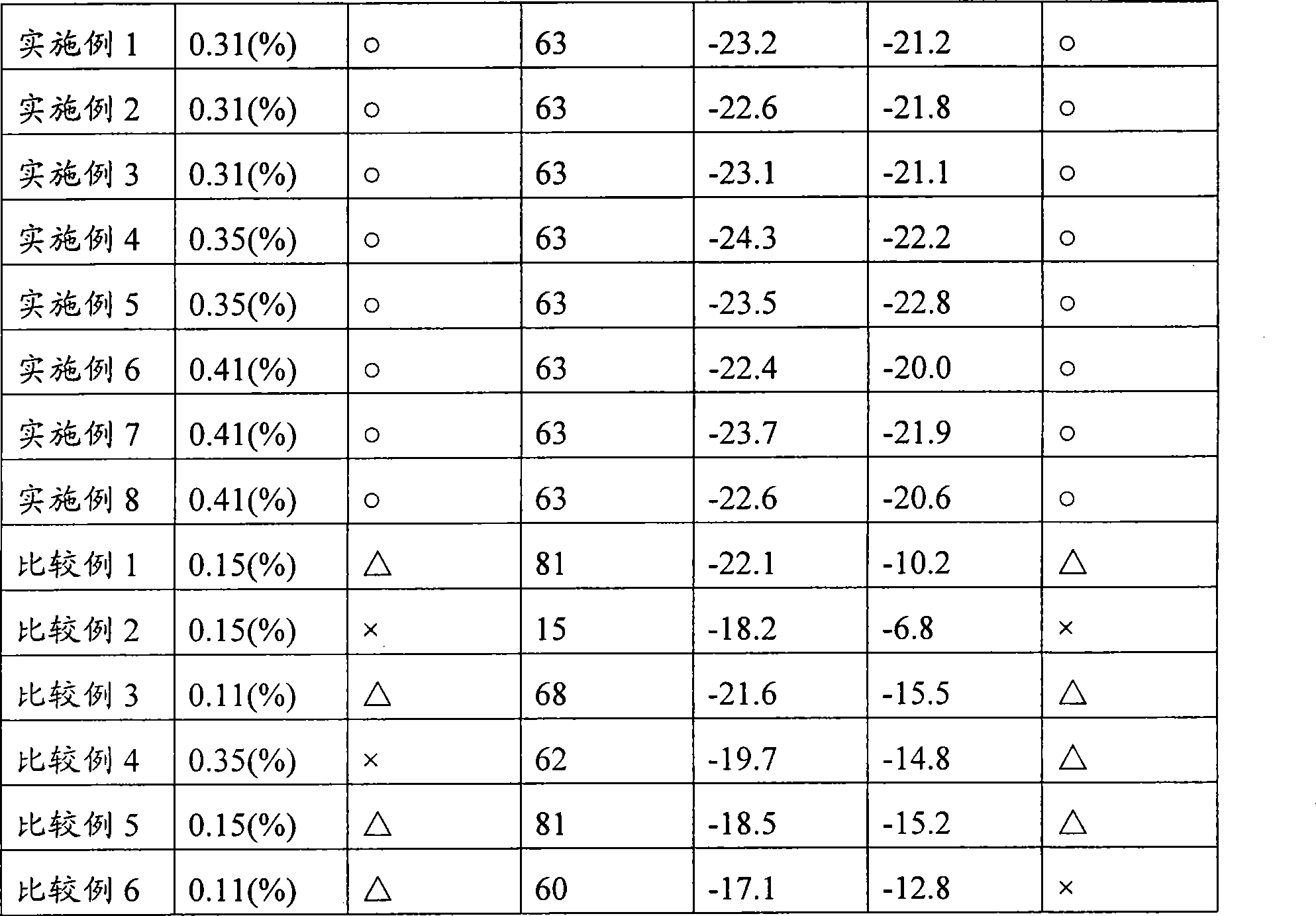

[0137] 40 g of commercially available trifluoropropyltrimethoxysilane (Dow Chemical Corporation Z-6333 CAS No 429-60-7) was dissolved in 200 g of ethanol solvent.

[0138] Then, commercially available (MT150 from Teika Co., Ltd.) with a water-soluble content of 0.31% was dispersed in toluene so that the solid content concentration was 37%, and the bead diameter was 0.5 mm. A bead mill (bead mill NVM-2 type manufactured by AIMEX Co.) was pulverized for about 2 hours to obtain particles with an average particle diameter of 0.047 μm (measured with NIKKISOmicro trackUPA-150), and weighed 630 g.

[0139] Further, the silane solution and the toluene solvent in which titanium dioxide was dispersed were mixed, and transferred to a 1 L four-necked flask installed in an oil bath. Use a stirrer at 60rpm to stir while shooting and heat up to 60°C, and react for 6 to 7 hours at the same time, then raise the temperature to 80°C. At this time, the amount of ethanol and toluene was collecte...

Synthetic example -B

[0142] Commercially available trifluoropropyltrimethoxysilane (Z-6333 from Toray Corporation) and methyltrimethoxysilane (Z-6366 from Toray Corporation) were dissolved in 200 g of methanol at an equivalent ratio of 40 g.

[0143] Then, commercially available (Teika Corporation MT150) titanium dioxide with a water-soluble content of 0.31% was dispersed in toluene so that the solid content concentration was 37%, and the bead diameter was 0.5 mm. A bead mill (bead mill NVM-2 type manufactured by AIMEX Co.) was pulverized for about 2 hours to obtain particles with an average particle diameter of 0.047 μm (measured with NIKKISOmicro trackUPA-150), and weighed 630 g.

[0144] Further, the silane solution and the toluene solvent in which titanium dioxide was dispersed were mixed, and transferred to a 1 L four-necked flask installed in an oil bath. Use a stirrer at 60rpm to stir while injecting the function temperature to 60°C, and react for 6 hours to 7 hours at the same time, then ...

Synthetic example -D

[0147] A mixture of commercially available trifluoropropyltrimethoxysilane (Z-6333 from Toray Corporation) and methyltrimethoxysilane (Z-6366 from Toray Corporation) dissolved in 190g of methanol solvent and 10g of water at an equal ratio of 40g middle. After the solution was left in a laboratory at 25°C for a day and night, a cloudy solution that was not observed in Synthesis Examples-A~C could be observed, and the surface treatment operation was performed in the same manner as Synthesis Examples-A~C.

[0148] When the gasification reaches 90% of the solvent amount relative to the prescribed amount, the set temperature is raised to 130°C to 140°C, and the temperature rise in the tank is confirmed. When the rise becomes slow, the pressure can be reduced. When the temperature in the tank exceeds 110°C, the decompression is stopped, and the calcining is performed for about 6 hours. At this time, a sample was sampled, and it was confirmed that the Rt peak due to the silylation r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com