Laminating machine used for vacuum microwave drying furnace

A vacuum microwave drying and stacking machine technology, which is applied in the direction of conveyors, winding strips, and sending objects, can solve the problems of inability to apply vacuum microwave drying ovens, reduce the physical properties of films, and bulky volume, so as to reduce the difficulty of maintenance , avoid being interrupted and destroyed, and reduce the volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention. In addition, it should be understood that after reading the teachings of the present invention, those skilled in the art can make various changes or modifications to the present invention, and these equivalent forms also fall within the scope defined by the appended claims of the present application.

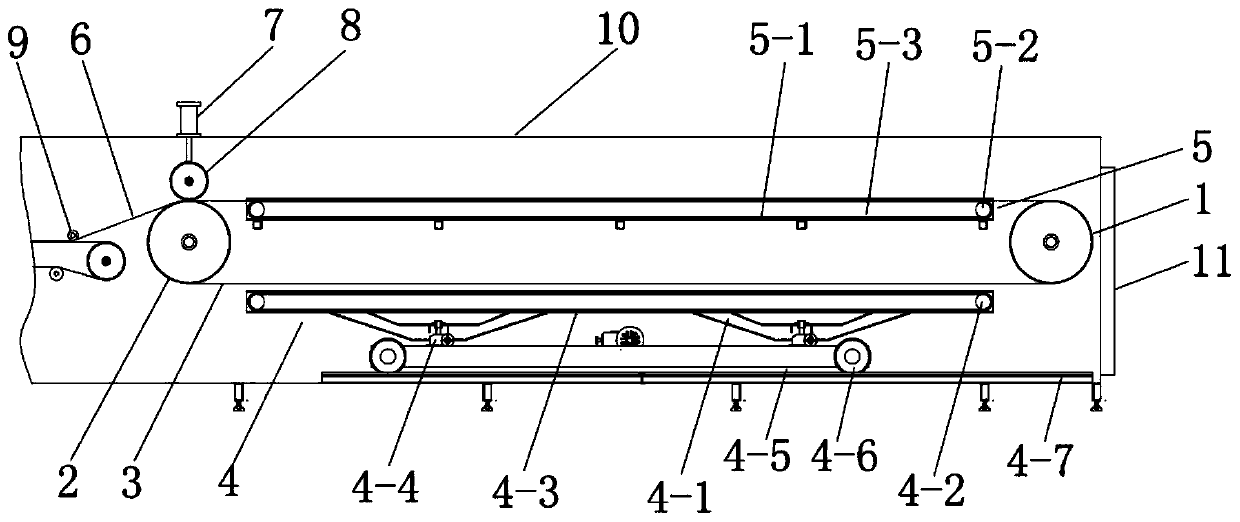

[0020] Such as figure 2 The lamination machine for a vacuum microwave drying oven shown includes a pulley 1, a pressure roller 2, a conveyor belt 3, a follower trolley 4, a belt supporting mechanism 5 and a tablet pressing mechanism.

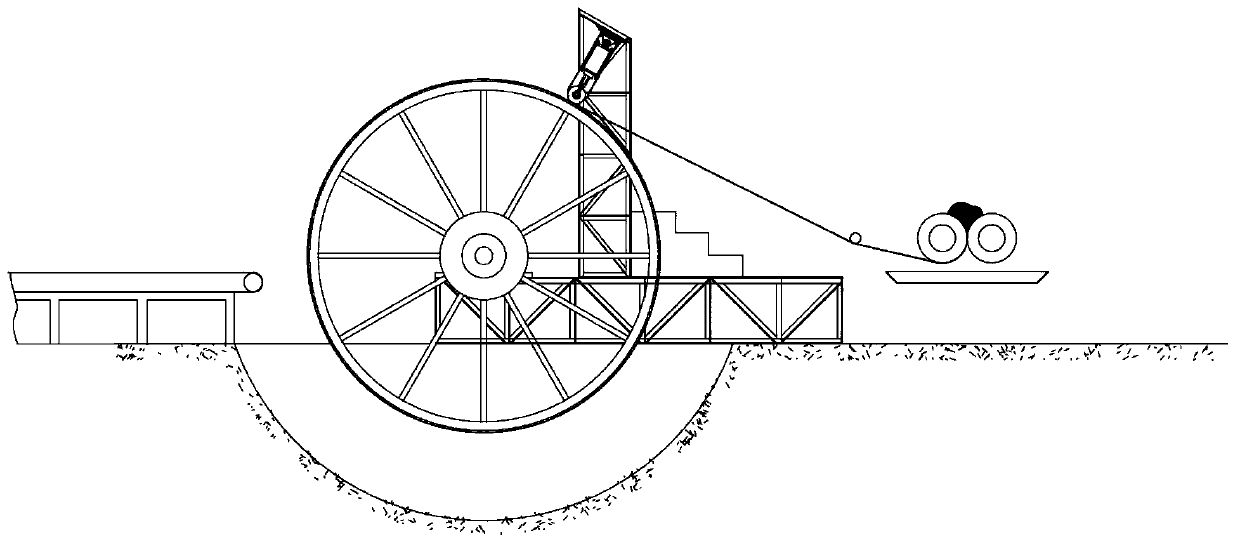

[0021] The stacking machine is arranged at the tail of the vacuum microwave drying oven 10, and the vacuum microwave drying oven 10 is a newly developed equipment for rubber film production. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com