Steel bar spraying equipment for wave-type anti-stirring bridge

A technology for spraying equipment and bridges. It is applied in the direction of spraying devices, etc. It can solve problems such as rusting and corrosion on the surface of steel bars, rust and corrosion on the surface of steel bars, and affect the color, so as to avoid large-area film formation or agglomeration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0024] Such as Figure 1-Figure 4 As shown, the present invention provides a kind of technical scheme of steel bar spraying equipment for wave type anti-stirring bridge:

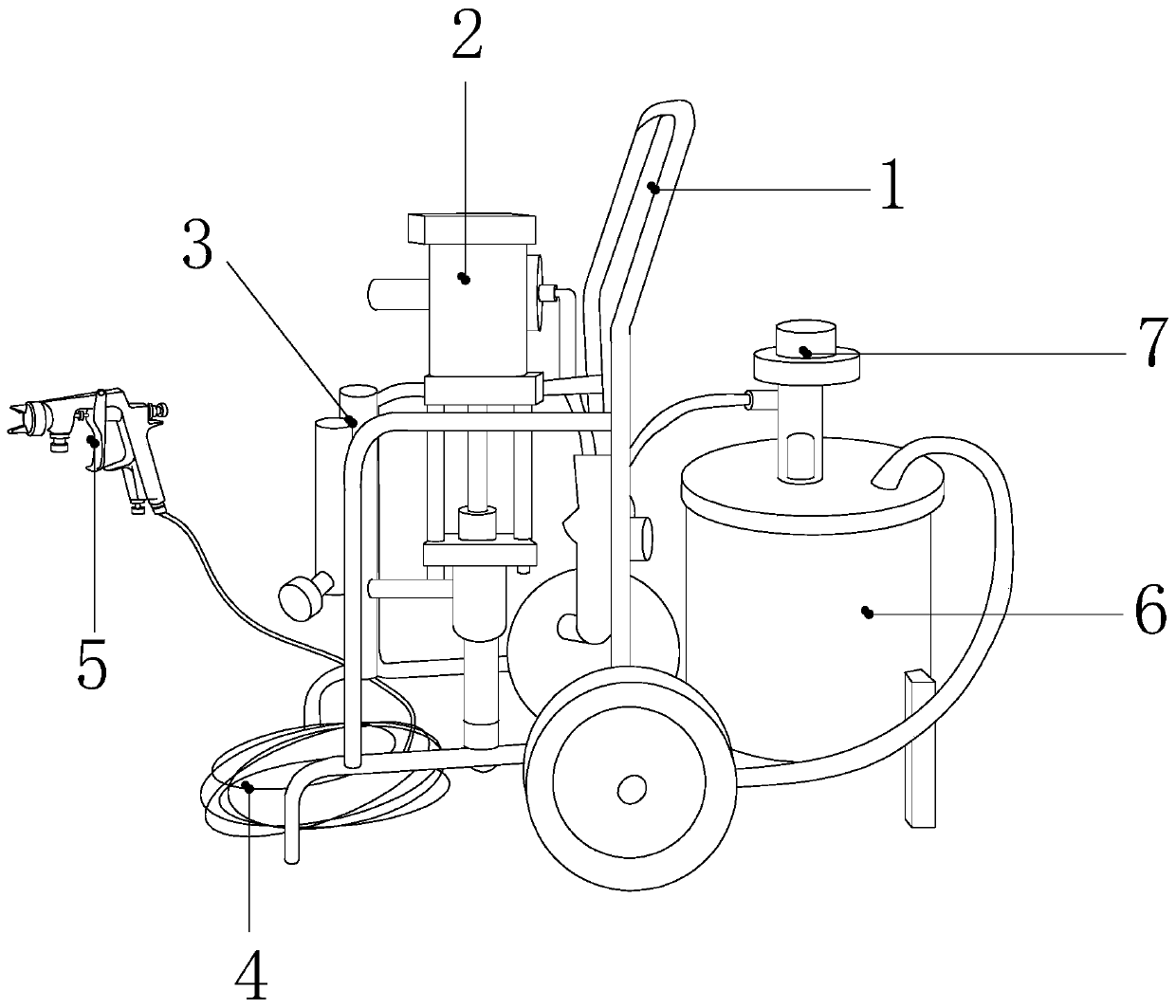

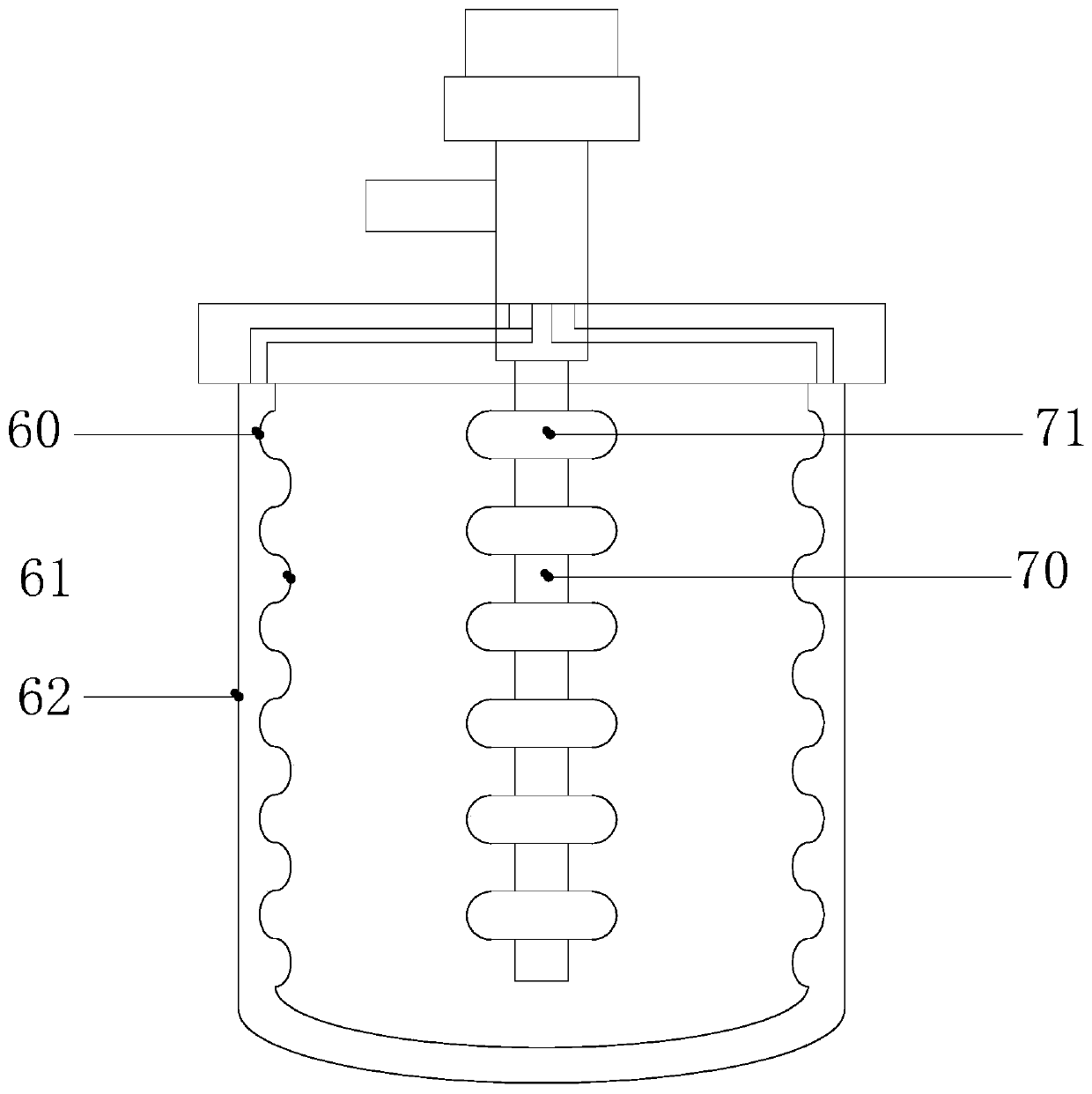

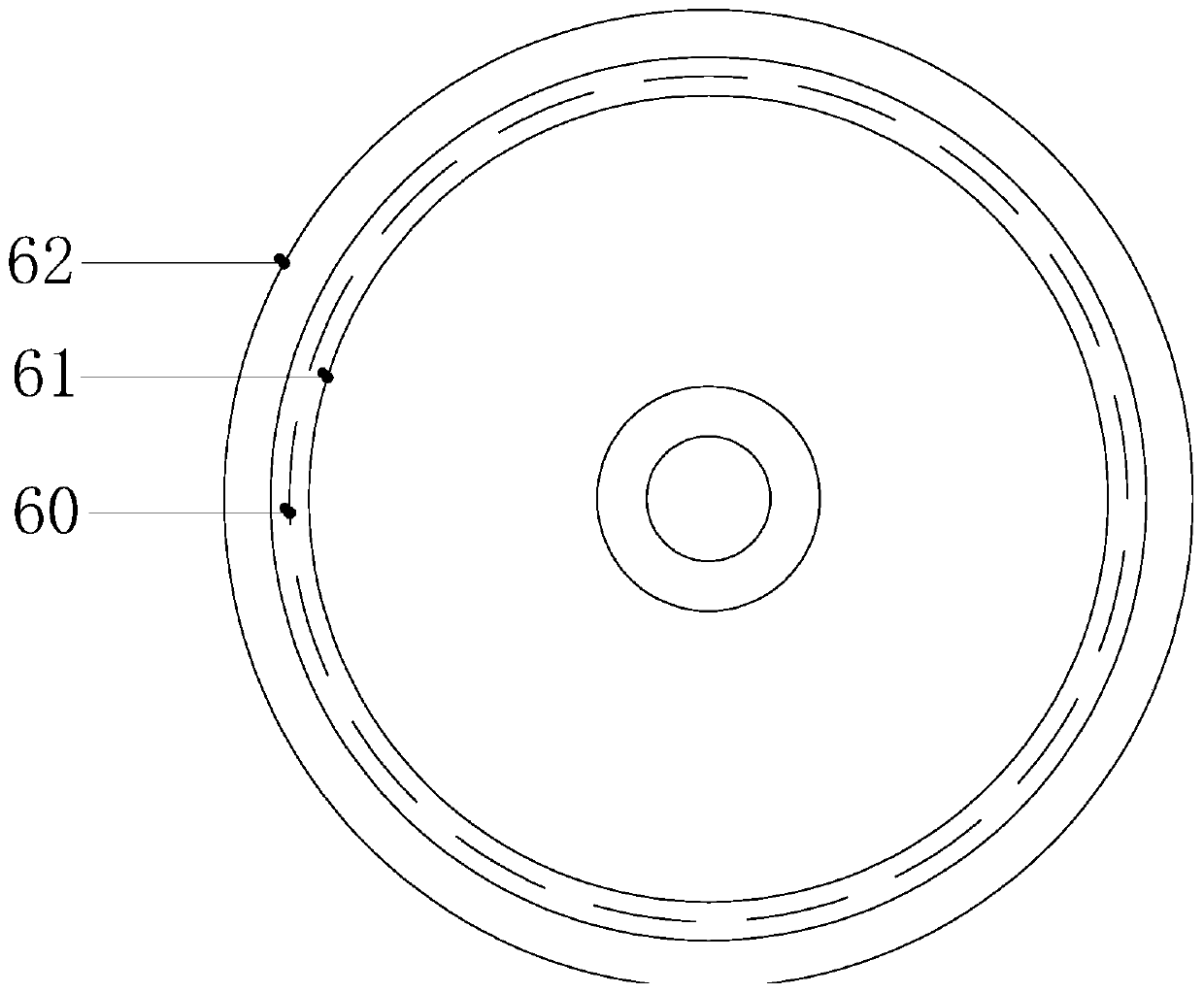

[0025] Such as Figure 1-Figure 2 Shown, a kind of wave-type anti-stirring bridge steel bar spraying equipment, its structure comprises trolley 1, air compressor 2, filter regulator 3, air pipe 4, spray gun 5, material storage tank 6, pneumatic mixer 7, described The air compressor 2 is installed in the middle of the cart 1 and connected by electric welding, the filter regulator 3 is electrically connected to the air compressor 2, the storage tank 6 is installed on the right side of the cart 1, and the storage tank 6 is connected to the spray gun 5 through the air pipe 4, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com