Deposition method and sputtering device

A film forming method and sputtering technology, which can be used in sputtering, vacuum evaporation, ion implantation and other directions, and can solve problems such as disturbing film quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

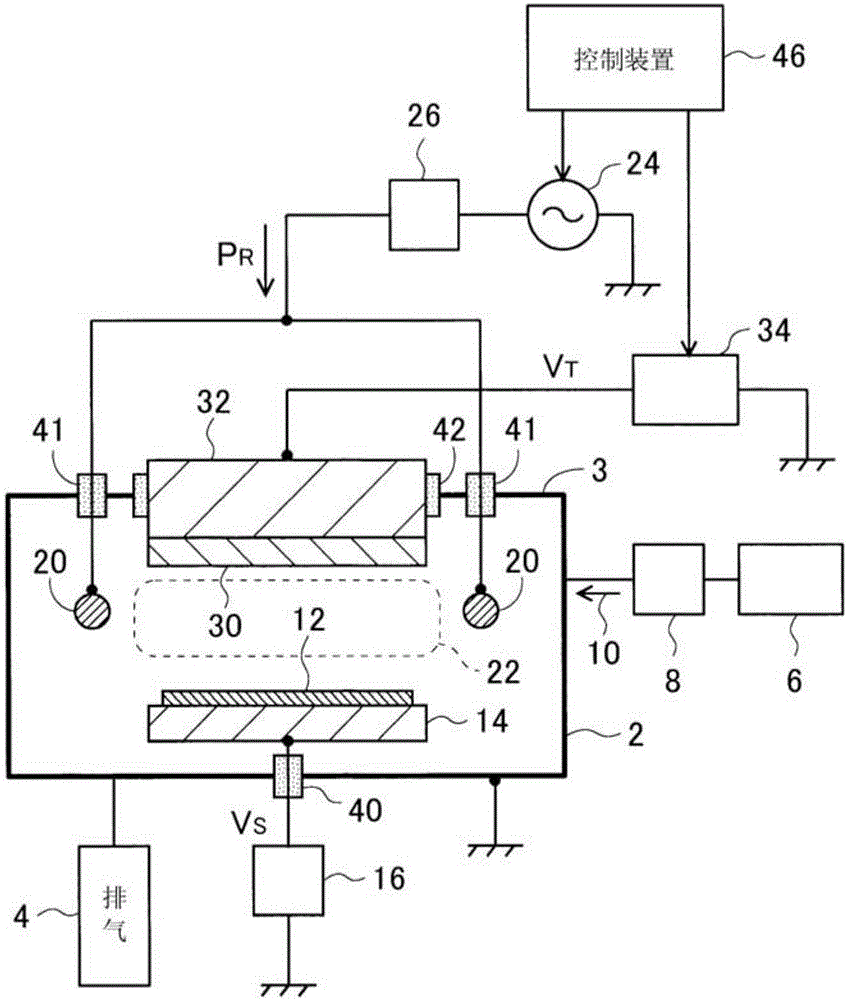

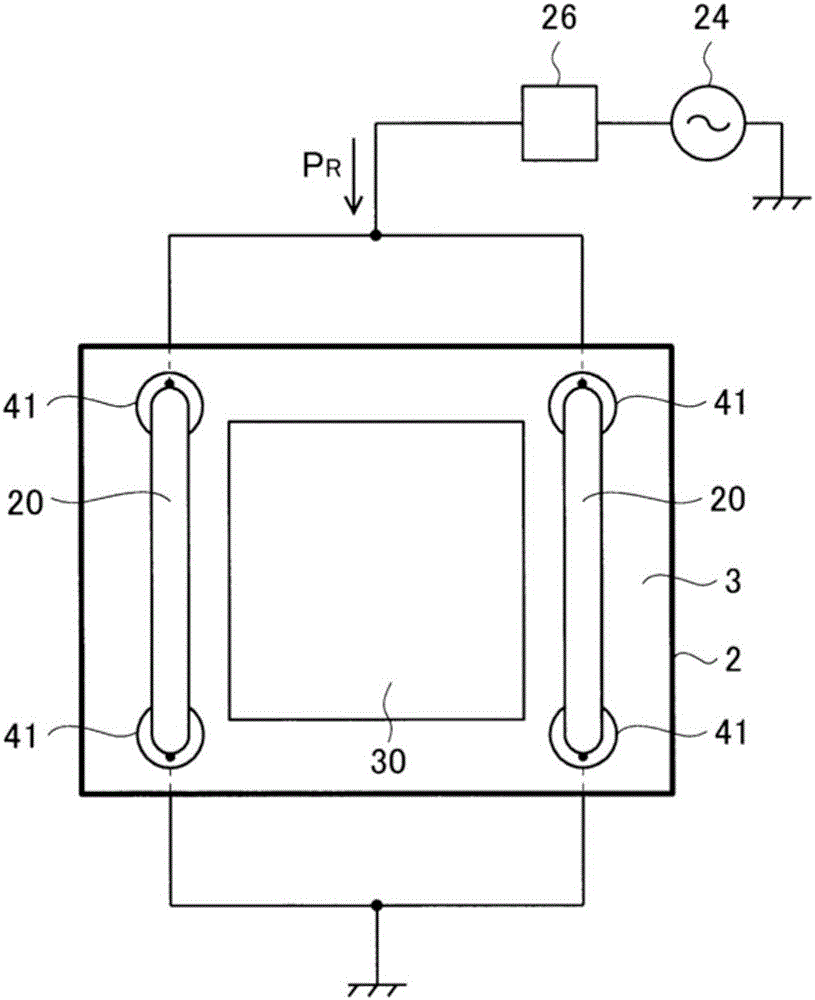

[0029] An example of a sputtering device for implementing the film forming method of the present invention is shown in figure 2 , will be observed from below figure 2 A diagram around the antenna of the device shown in the image 3 middle. exist figure 2 , conceptually represents the high-frequency power P for each antenna 20 R The power supply section, regarding the power supply section, will refer to image 3 And later.

[0030] The sputtering device includes a vacuum container 2 that is evacuated by a vacuum exhaust device 4, and the vacuum container 2 is electrically connected to the ground.

[0031] A sputtering gas 10 is introduced into the vacuum vessel 2 . In the above example, the gas is introduced from the gas source 6 through the flow regulator 8 . The gas 10 is, for example, argon. When reactive sputtering is performed, the gas 10 may be a mixed gas of argon and active gas (such as oxygen, nitrogen, etc.).

[0032] A substrate holder 14 holding a substr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com