Electronic transformer coil winding and stripping device

A technology of electronic transformers and winding devices, which is applied in the manufacture of coils, etc., can solve problems such as damage to coils, coil bumps, etc., and achieve the effects of easy arrangement, avoiding damage to the skeleton, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

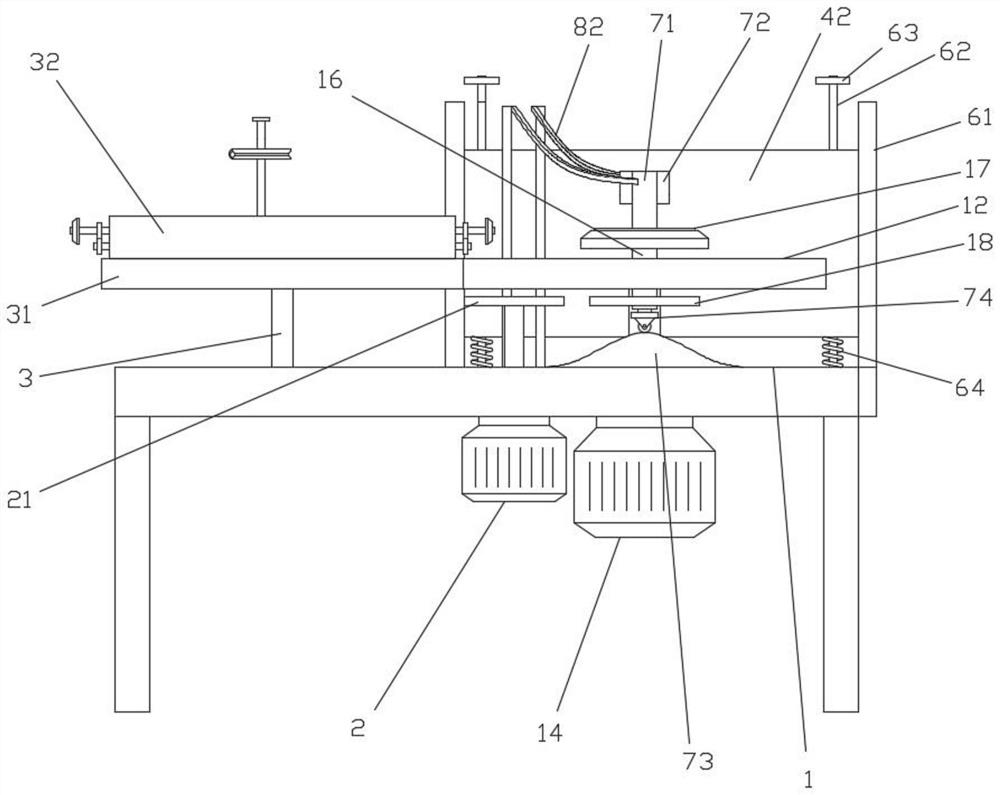

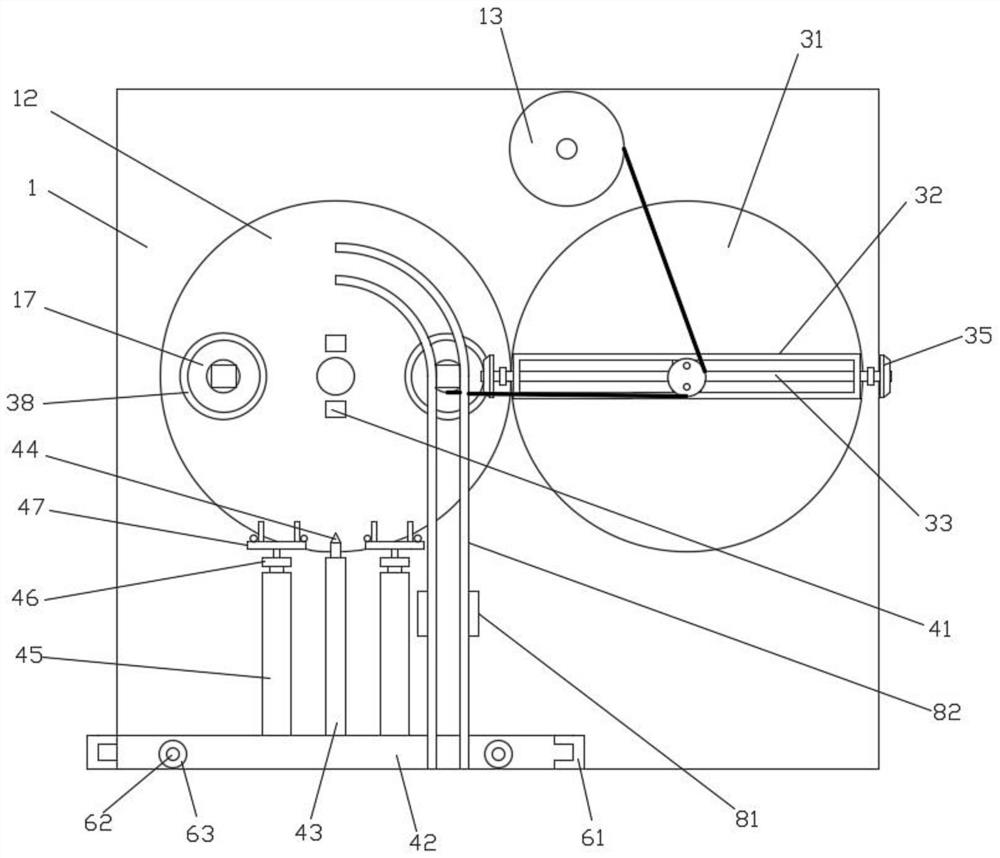

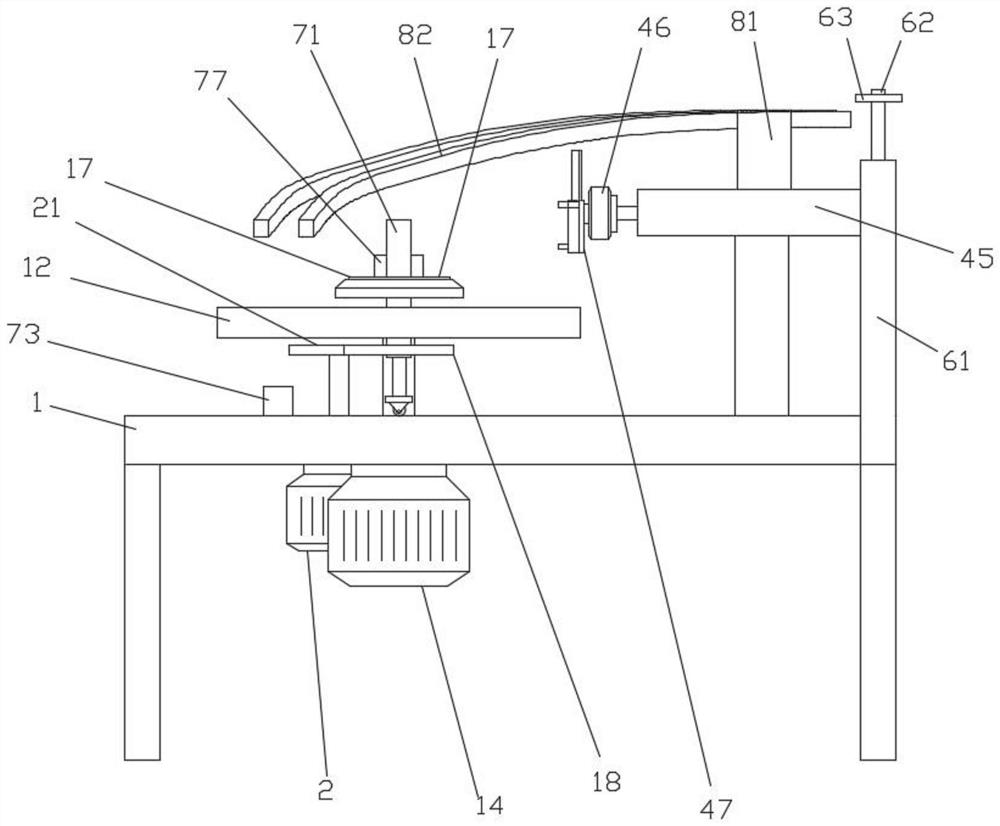

[0029] like Figure 1-7 Shown; A kind of electronic transformer coil winding stripping device, comprises:

[0030] Coil base 1, a turntable 12 and a wire reel seat 13 are installed on the coil base 1, the turntable 12 is driven by a stepper motor 14, and the stepper motor 14 is installed on the bottom of the coil base 1, and the turntable 12 is symmetrically installed with Two one-way bearing seats 15, two one-way bearing seats 15 are symmetrical about the axis of the turntable 12, each one-way bearing seat 15 is independently installed with a coil material shaft 16, and the upper end of the coil material shaft 16 is fixed with a material table 17, and the coil material shaft 16 lower end is fixed with driven gear 18;

[0031] Drive motor 2, the drive motor 2 is fixed on the lower part of the coil base 1, the output end of the drive motor 2 is fixed with a drive gear 21, the drive gear 21 is located between the turntable 12 and the coil base 1, and the driven gear 18 revolves...

Embodiment 2

[0040] On the basis of Example 1, such as Figure 1-5 As shown; the material distribution shaft 3 is rotated on the coil base 1, and the distribution shaft 3 is fixed with a steering gear 31. A guide channel 32 is installed on it;

[0041] A first support screw 33 and a second support screw 34 are installed in the guide channel 32 for rotation, a first transmission gear 35 is fixedly installed on the first support screw 33, a second transmission gear 36 is fixedly installed on the second support screw 34, The first transmission gear 35 meshes with the second transmission gear 36, the two ends of the first support screw 33 are respectively equipped with bevel gears 37, the outer ring of the table 17 has a bevel gear ring 38, and the bevel gear 37 at one end of the first support screw 33 is engaged The bevel ring 38, the first support screw 33 is equipped with a moving seat 39, the moving seat 39 is equipped with a reciprocating screw 310 and a guide rod 311, and one end of the...

Embodiment 3

[0049] On the basis of Example 2, such as Figure 1-5 as well as Figure 8 As shown; the middle part of the turntable 12 is fixedly equipped with a knife seat 41, and the side of the coil base 1 is provided with a side plate 42, and a first electric push rod 43 is fixedly installed on the side plate 42, and the output end of the first electric push rod 43 faces the knife. Seat 41 is arranged, and the cutter 44 is fixed on the first electric push rod 43, and the second electric push rod 45 is respectively installed on the side plate 42 on both sides of the first electric push rod 43, and each second electric push rod 45 output end Steering motors 46 are installed respectively, the second electric push rod 45 is arranged one-to-one with the material table 17, the output end of the steering motor 46 is fixedly installed with a clamping plate 47, and the second electric push rod 45 is perpendicular to the clamping plate 47;

[0050] Two guide rails parallel to each other are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com